Sand-resistant gate valve

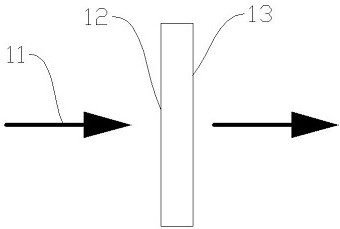

A gate valve and gate technology, which is applied to valve devices, valve details, sliding valves, etc., can solve the problems of sedimentation, limited vibration effect of knocking, and valves that cannot be completely closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

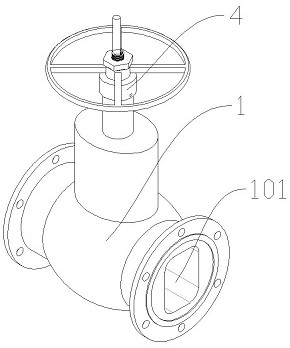

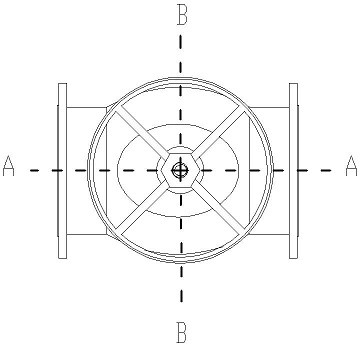

[0024] Please refer to Figure 2 to Figure 5 , figure 2 is a perspective view of the gate valve of this embodiment, image 3 Yes figure 2 top view, Figure 4 Yes image 3 Sectional view along section A-A, Figure 5 Yes image 3 Sectional view of section B-B.

[0025] The gate valve includes a valve body 1 , a gate 2 , a valve seat 3 and a driving structure 4 . The valve body 1 is provided with a fluid channel 101 that runs through the body as a channel for fluid flow; the valve seat 3 is located in the fluid channel 101 and is perpendicular to the fluid flow direction, and the driving structure 3 is used to drive the gate 2 to slide back and forth along the valve seat 3 so as to Open and close the fluid channel 101 .

[0026] The drive structure 4 includes a handwheel 401 and a valve stem 402. One end of the valve stem 402 is inserted into the valve body 1 and connected to the gate 2, and the valve stem 402 is sealedly connected to the valve body 1. The handwheel 401...

Embodiment 2

[0031] In order to further improve the flushing effect, part of the structure in Example 1 is improved in this implementation.

[0032]First of all, in order to reduce the gap between the bottom of the shutter 2 and the top of the first baffle 3012 when the shutter 2 is in the first position, a clearance fit is adopted between the shutter 2 and the first baffle 3012, and a clearance fit is adopted between the shutter 2 and the first baffle 3012. An elastic layer is provided on the upstream surface to seal the gap between the gate 2 and the first baffle 3012 .

[0033] Secondly, in order to prevent large particles from being intercepted, increase the minimum flow area of the flow channel between the bottom of the gate 2 and the groove 3012. For details, refer to Figure 13 , the upper end of the first baffle 3012 is higher than the upper end of the second baffle 3013, and when the gate 2 is in the first position, the minimum flow area of the flow passage between the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com