Catalyst for preparing alcohol through methane electro-oxidation and preparation method and application thereof

A catalyst and electro-oxidation technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of lack of practical application value and high catalyst cost, and achieve high selectivity and the effect of inhibiting deep oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] An embodiment of the present invention provides a method for preparing a catalyst, which can be used for the electro-oxidation of methane to alcohol, comprising the following steps:

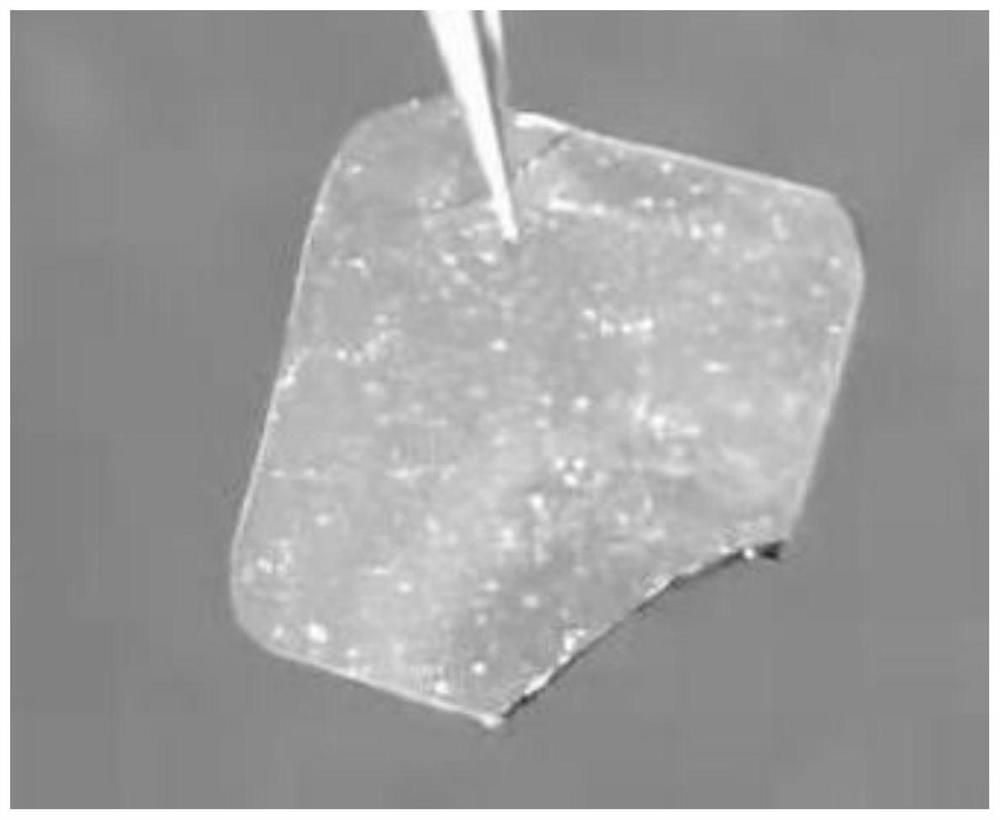

[0066] S1. Preparation of reduced graphene oxide dispersion

[0067] The graphene oxide (GO) dispersion is mixed evenly with ammonia water and hydrazine hydrate, and the reaction is carried out at 70°C-100°C for 0.5h-4h to obtain a reduced graphene oxide (rGO) dispersion, and stirring is maintained during the preparation process.

[0068] In order to further control the sufficient reduction of graphene oxide, the concentration of graphene oxide dispersion liquid is 0.05mg / mL-0.5mg / mL (such as 0.05mg / mL, 0.1mg / mL, 0.2mg / mL, 0.3mg / mL, 0.4mg / mL) / mL, 0.5mg / mL), ammonia water is an aqueous solution with an ammonia content of 25-28wt%, hydrazine hydrate is an aqueous solution with a hydrazine hydrate content of 80-90wt%, and the volume ratio of ammonia water to graphene oxide dispersion is 1:(1...

Embodiment 1

[0096] The present embodiment provides a preparation method of a catalyst, comprising the following steps:

[0097] (1) Graphene oxide was prepared according to the Hummers method, and deionized water was injected into the prepared graphene oxide to obtain a GO dispersion with a concentration of 0.2 mg / mL. Take 100 mL of the GO dispersion and mix it with ammonia water and hydrazine hydrate. Among them, the volume ratio of ammonia water and GO dispersion liquid is 1:1000, and the volume ratio of hydrazine hydrate and GO dispersion liquid is 1:10000, and the rGO dispersion liquid is obtained by refluxing at 80 °C for 1 h.

[0098] (2) Use a syringe pump to slowly inject the zinc acetate solution into the NaOH solution. The concentration of zinc acetate in the mixed solution is 1mM, and the mass concentration ratio of zinc acetate and NaOH is 1:4. Stir evenly and heat at 80 °C for 1 h to obtain a ZnO colloidal solution. Dilute with deionized water to a target concentration of 0....

Embodiment 2

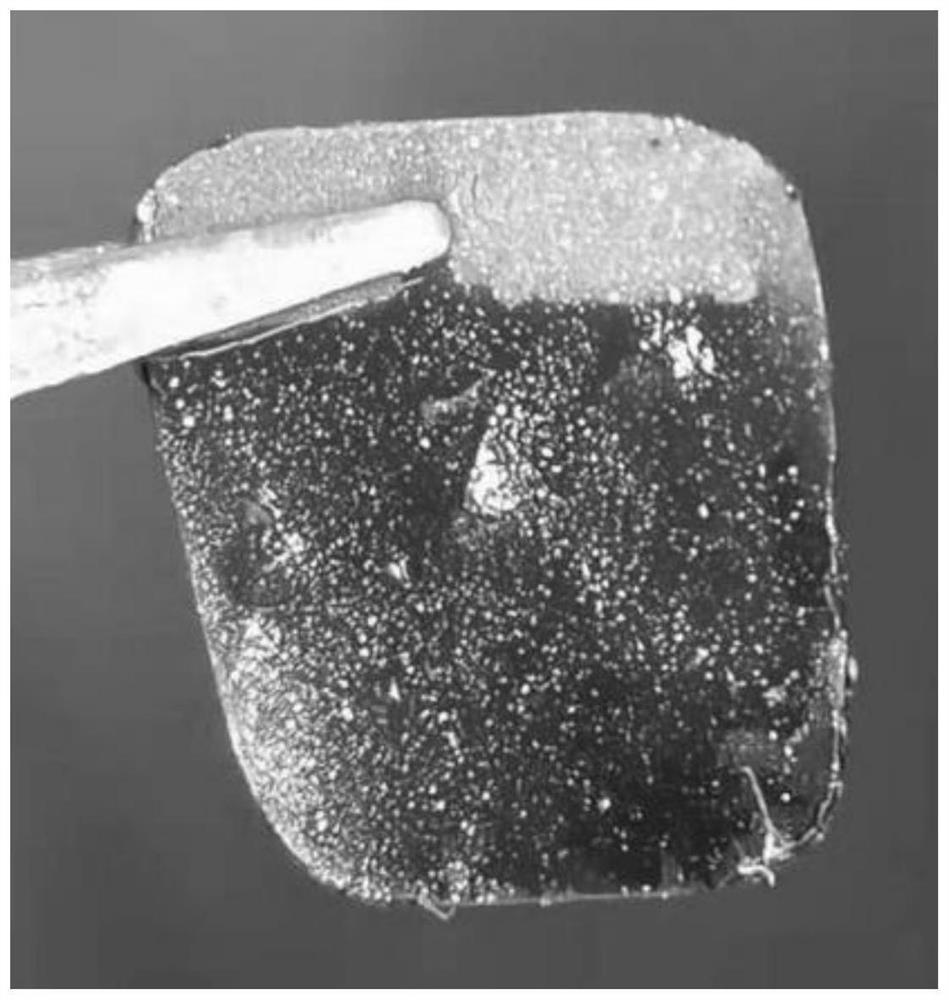

[0136] The present embodiment provides a preparation method of a catalyst, comprising the following steps:

[0137] (1) 100 mL of GO dispersion with a concentration of 0.2 mg / mL was uniformly mixed with ammonia water and hydrazine hydrate. Among them, the volume ratio of ammonia water and GO dispersion was 2.8:1000, the volume ratio of hydrazine hydrate and GO dispersion was 5.1:10000, and the rGO dispersion was obtained by refluxing at 90 °C for 0.5 h.

[0138] (2) Use a syringe pump to slowly inject the zinc acetate solution into the NaOH solution, the concentration of zinc acetate in the mixed solution is 7.5mM, and the ratio of the concentration of zinc acetate to NaOH is 1:4, stir evenly and heat at 60°C for 2h to obtain a ZnO colloidal solution, Deionized water was added to dilute to a target concentration of 0.2 mg / mL.

[0139] (3) The ZnO colloidal solution and the rGO dispersion (100 mL) were mixed in a volume ratio of 2:1, and vacuum filtered through the mixed cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com