Carbon sequestration reinforced recycled aggregate preparation device and method based on returned material crushing

A technology for regenerating aggregates and preparing devices, which is applied in solid waste management, climate sustainability, sustainable waste treatment, etc. The processing capacity, the instantaneous force is large, and the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below through specific embodiments.

[0038] refer to Figure 1 to Figure 4 As shown in the figure, a carbon-fixing-strengthened recycled aggregate preparation device based on return crushing includes a screw conveyor 1, a material throwing rotor 2, a screening drum 3, a return drum 4, a carbon dioxide input pipe 5, and an outer casing 6 , dust collector 7, absorption tank 71, graded aggregate screen 8, raw material conveyor 9;

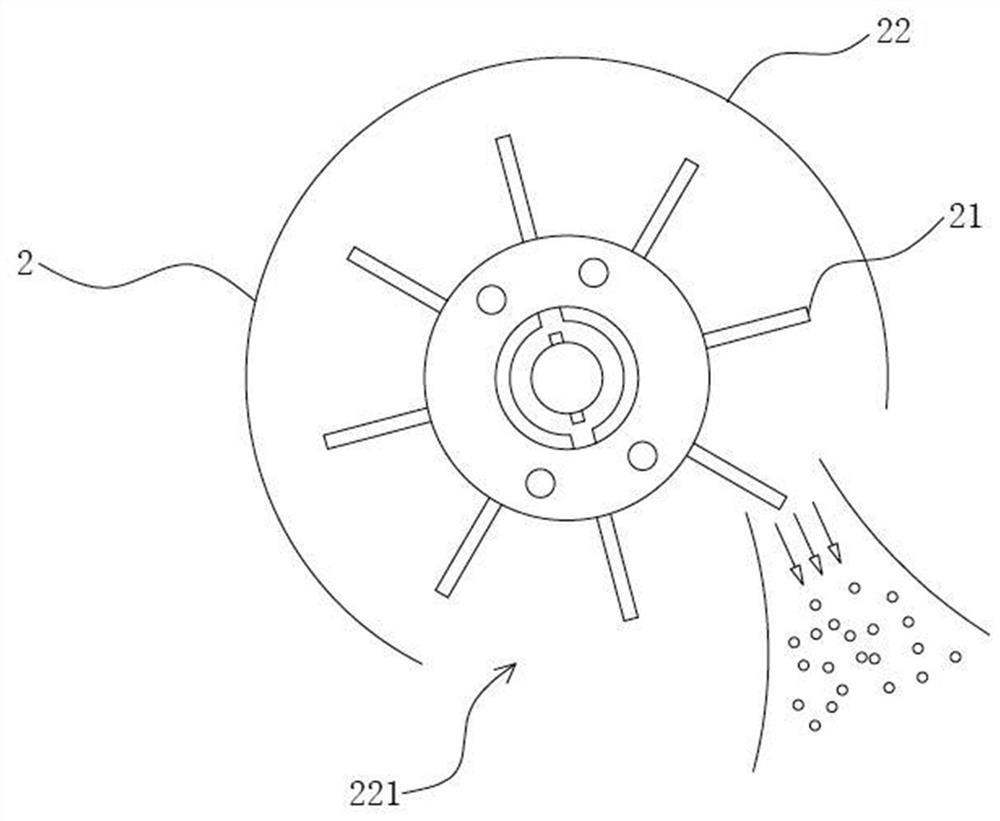

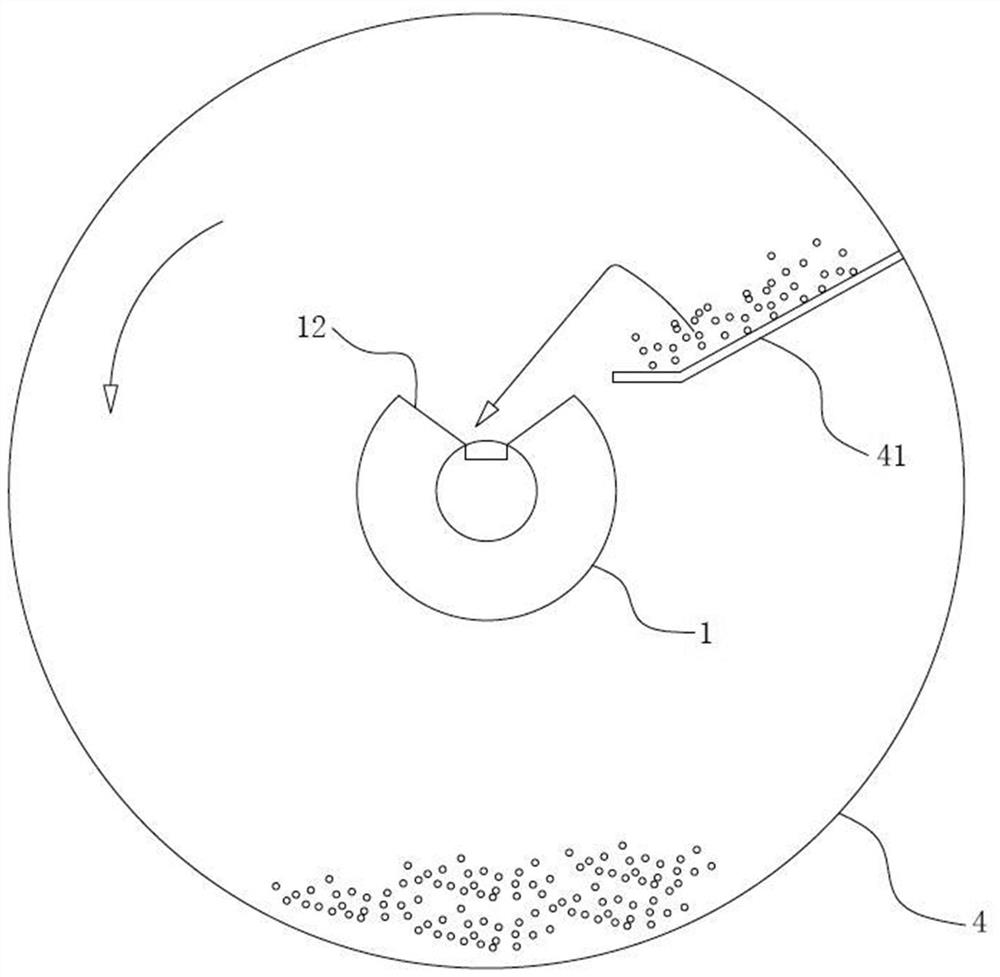

[0039] The screw conveyor 1 includes a raw material inlet 11, a fine aggregate inlet 12, and a discharge port 13. The raw material conveyor 9 is connected to the raw material inlet 11 of the screw conveyor 1, and the material throwing rotor 2 is provided in the screw conveyor. 1 one end and the discharge port 13 leads into the throwing rotor 2, and the screw conveyor 1 sends the aggregate into the throwing rotor 2;

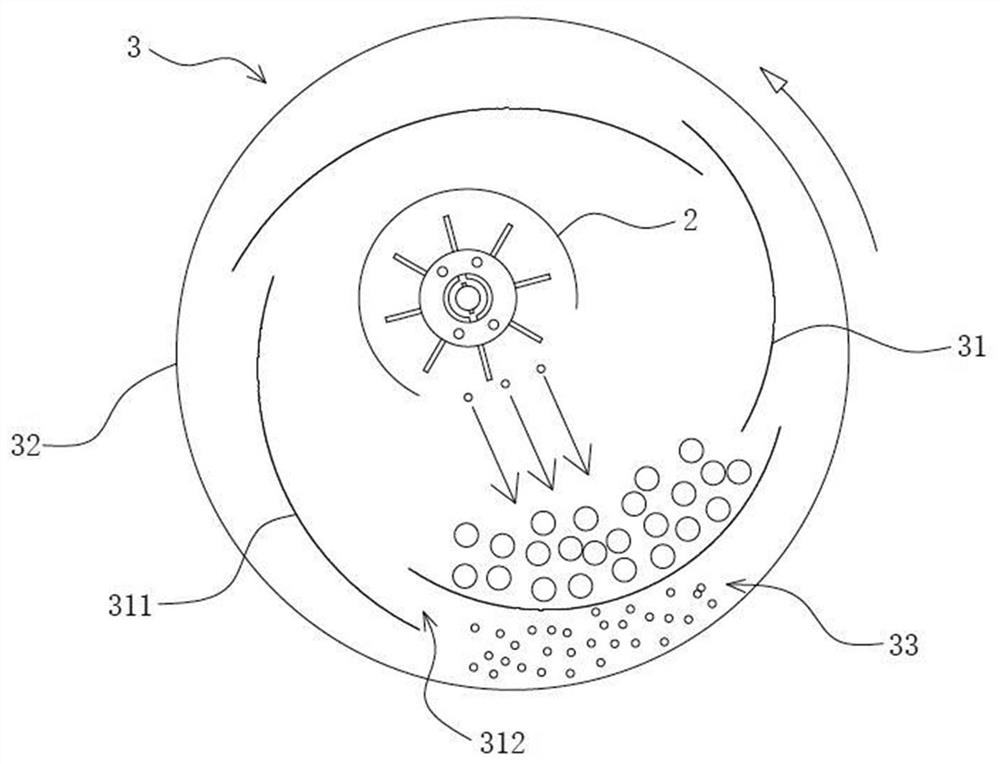

[0040]The screening drum 3 includes an inner cylinder 31 and an outer cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com