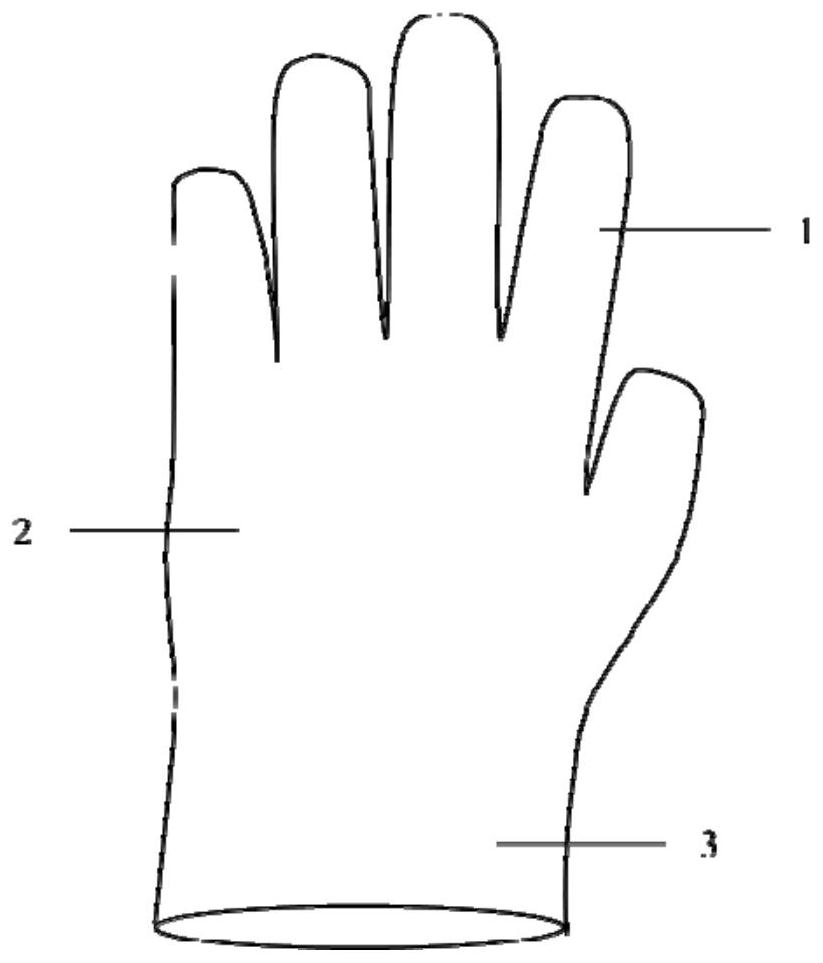

Cool, moisture-absorbing and sweat-releasing flexible stab-resistant glove

A moisture-absorbing, sweat-wicking, cool-feeling technology, applied to gloves, protective clothing, clothing, etc., can solve problems such as easy sweating, high cost, and poor wearing comfort of gloves, and achieve overall lightness and softness, good stab resistance and fit sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

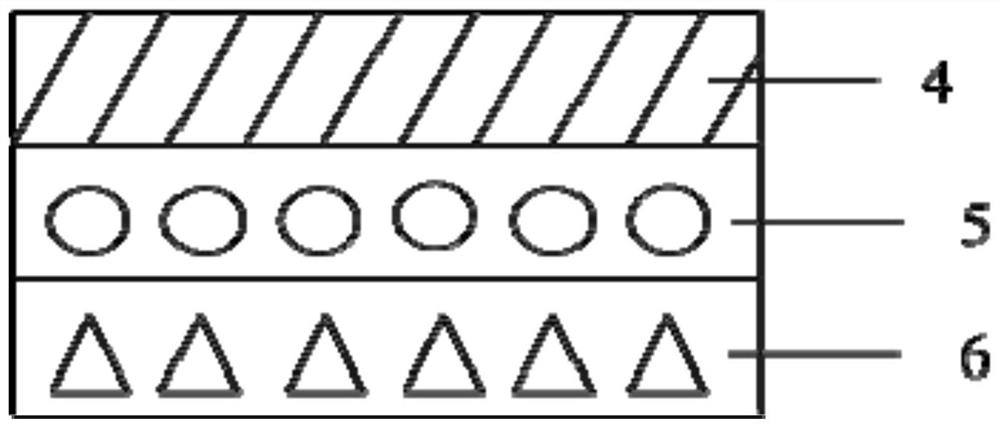

[0027] The preparation method of this cool feeling layer 4 comprises the following steps:

[0028] (a) soaking the cotton fiber non-woven fabric in the padding solution containing xylitol cooling feeling finishing agent;

[0029] (b) arranging the non-woven cotton fiber filled with padding liquid obtained in step (a) between two rollers for squeezing;

[0030] (c) drying the cotton fiber non-woven fabric obtained in step (b) in an oven.

[0031] Wherein, the mass concentration of the padding liquid is 80 g / L; in the step (a), the soaking time is 3 min; in the step (b), the rolling liquid ratio reaches 90% In the step (c), the drying temperature is 120° C., and in the step (c), the drying time is 2 min.

[0032] The absorbent layer 5 is made of viscose fibers. The moisture-absorbing layer 5 is a spunlace non-woven fabric. The thickness of the moisture-absorbing layer 5 is 0.5-0.8 mm. Viscose fiber has good hygroscopicity, and the spunlace non-woven fabric is flexible entan...

Embodiment 1

[0036] The raw material of the cool-sensing layer 4 is a cotton fiber non-woven fabric with a thickness of 0.5 mm, and a xylitol cool-sensing finishing agent is used to finish the cotton fiber non-woven fabric by a padding method, and the mass concentration of the padding solution is 80g / L, soaking The duration is 3 minutes, and two rollers are used to squeeze and roll the cotton fiber non-woven filled with padding liquid, and the rolling ratio is 90%, and it is dried in an oven at a drying temperature of 120° C. and the duration is 2 minutes. The raw material of the moisture-absorbing layer 5 is viscose fiber spunlace non-woven fabric with a thickness of 0.6 mm. The raw material of the stab-proof layer 6 is a woven fabric blended with high-strength polyester filament and spandex fiber, and the yarn blending ratio is 90:10. The cool feeling layer 4, the moisture absorption layer 5 and the stab-proof layer 6 are point-bonded by adhesives to ensure the breathability of the glove...

Embodiment 2

[0039] The glove consists only of the cooling layer 4 and the anti-stab layer 6 . The raw material of the cool-sensing layer 4 is a cotton fiber non-woven fabric with a thickness of 0.5 mm, and a xylitol cool-sensing finishing agent is used to finish the cotton fiber non-woven fabric by a padding method, and the mass concentration of the padding solution is 80g / L, soaking The duration is 3 minutes, and two rollers are used to squeeze and roll the cotton fiber non-woven filled with padding liquid, and the rolling ratio is 90%, and it is dried in an oven at a drying temperature of 120° C. and the duration is 2 minutes. The raw material of the stab-proof layer 6 is a woven fabric blended with high-strength polyester filament and spandex fiber, and the yarn blending ratio is 90:10. The cool-sensing layer 4 and the stab-proof layer 6 are point-bonded with an adhesive, and then cut and stitched to obtain a cool-sensing flexible stab-proof glove.

[0040] The result of this example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com