Preparation method of carbon black dispersion liquid for black polyimide film

A technology of polyimide film and dispersion liquid, which is applied in the field of preparation of carbon black dispersion liquid for black polyimide film, can solve the problem of deterioration of dispersion condition, difficulty and large workload of dispersant selection, and selection range of dispersant. Narrowing etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Experimental raw materials: N,N-dimethylacetamide (DMAc), pyromellitic dianhydride (PMDA), 4,4'-diaminodiphenyl ether (ODA), carbon black (brand: Orilon FW200; PH value 2.5);

[0053] Experimental equipment: double-layer glass reactor, circulating cooler, electric stirrer, sand mill;

[0054] Add 695g of DMAc to the double-layer glass reactor, add 60g of ODA, start the electric stirrer and stir at 150r / min for 30min, divide 45g of PMDA into two equal parts, slowly add the first part of dianhydride to the reactor, and stir for 15min. Then slowly add the second part of dianhydride into the reactor, stir for 30min, and control the polymerization temperature between 45±2°C during the reaction. After adding 200g of carbon black (brand: Orilong FW200, pH 2.5) and stirring evenly, the slurry was ground with a sand mill at 2800r / min for 10 hours.

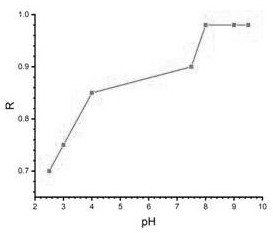

[0055] The mass percentage of carbon black in the obtained dispersion was 20%, the molar ratio of PDMA to ODA was 0.7 (R=0.7), an...

Embodiment 2

[0058] This example is similar to the technical solution adopted in Example 1, except that the carbon black brand used is LampBLACK 101 (the pH value of the product is 7.5), and the quality of the PDMA used is 58.81 g (R=0.9 at this time). ).

[0059] After testing, the median particle size of carbon black in the prepared carbon black dispersion was 50 nm (D 50 = 50nm) for 90 days: no sedimentation.

Embodiment 3

[0060] Example 3: Preparation of carbon black dispersion for black polyimide film

[0061] This example is similar to the technical solution adopted in Example 1, except that the carbon black brand used is PRINTEX L6 (commodity pH value is 9.5), and the quality of the PDMA used is 64g (R is 0.98 at this time) .

[0062] After testing, the median particle size of carbon black in the prepared carbon black dispersion was 50 nm (D 50 =50nm), placed for 90 days without sedimentation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com