Dielectric energy storage ceramic powder, preparation method and application of dielectric energy storage ceramic powder in ceramic membrane

A ceramic powder, dielectric technology, applied in the direction of the conductive layer on the insulating carrier, can solve the problems of small dielectric loss, slow heat dissipation, and high equipment requirements, achieve small leakage current, avoid thermal breakdown, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

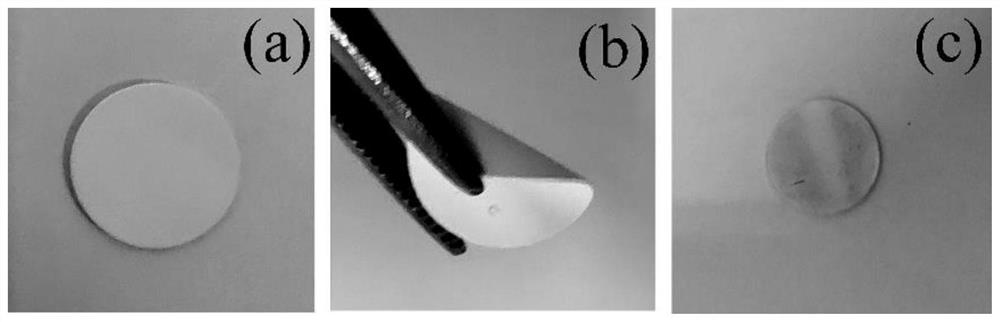

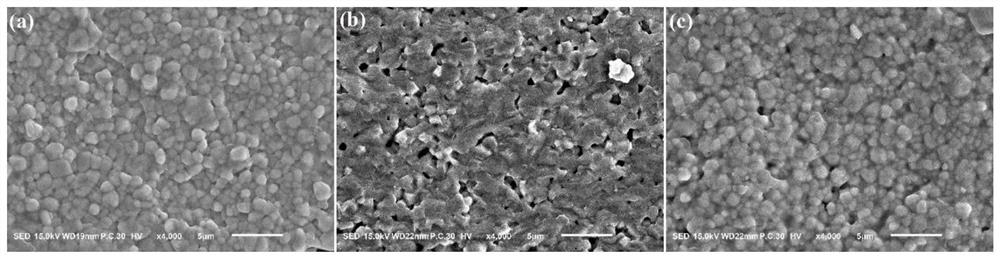

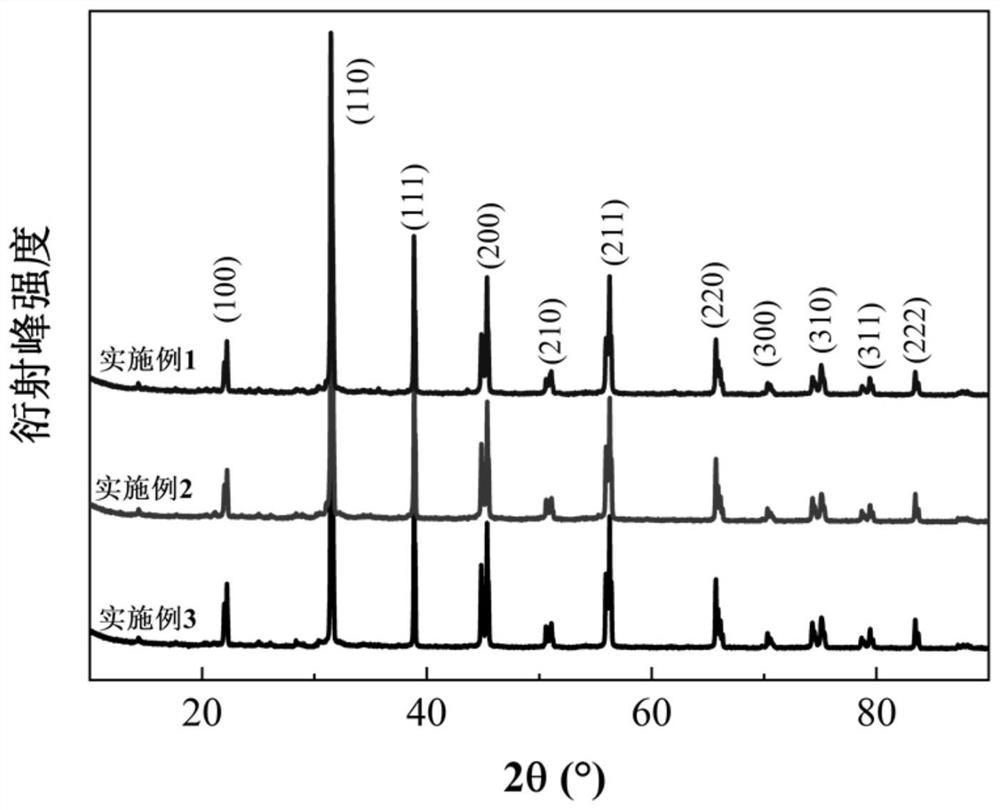

[0052] Embodiment 1: A kind of dielectric energy storage ceramic powder, preparation method and its application in ceramic membrane

[0053] The dielectric energy storage ceramic powder provided in this embodiment has a molecular formula of (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 .

[0054] Its preparation method is as follows:

[0055] with BaCO 3 , La 2 O 3 , Li 2 CO 3 , TiO 2 and MgO as raw materials, the powder is ground and mixed by the ball milling process, and it is prepared by pre-sintering after sieving, wherein the proportion of each component is according to (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 Weigh, use zirconia balls with diameters of 5mm, 10mm, 15mm and 20mm as the grinding medium, deionized water as the grinding dispersant, use the ball mill to run alternately forward and reverse, and grind for 48h to obtain a mixed powder; dry the powder Passing through a 100-mesh sieve and pre-firing to obtain a dielectric energy storage cer...

Embodiment 2

[0065] Embodiment 2: A kind of dielectric energy storage ceramic powder, preparation method and its application in ceramic membrane

[0066] The dielectric energy storage ceramic powder provided in this embodiment has a molecular formula of (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 .

[0067] Its preparation method is as follows:

[0068] with BaCO 3 , La 2 O 3 , Li 2 CO 3 , TiO 2 and MgO as raw materials, the powder is ground and mixed by the ball milling process, and it is prepared by pre-sintering after sieving, wherein the proportion of each component is according to (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 Weigh, use zirconia balls with diameters of 5mm, 10mm, 15mm and 20mm as the grinding medium, deionized water as the grinding dispersant, use the ball mill to run alternately forward and reverse, and grind for 48h to obtain a mixed powder; dry the powder Passing through a 100-mesh sieve and pre-firing to obtain a dielectric energy storage cer...

Embodiment 3

[0078] Embodiment 3: A kind of dielectric energy storage ceramic powder, preparation method and its application in ceramic membrane

[0079] The dielectric energy storage ceramic powder provided in this embodiment has a molecular formula of (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 .

[0080] Its preparation method is as follows:

[0081] with BaCO 3 , La 2 O 3 , Li 2 CO 3 , TiO 2 and MgO as raw materials, the powder is ground and mixed by the ball milling process, and it is prepared by pre-sintering after sieving, wherein the proportion of each component is according to (Ba 0.88 La 0.1 Li 0.02 )(Ti 0.96 Mg 0.04 )O 3 Weigh, use zirconia balls with diameters of 5mm, 10mm, 15mm and 20mm as the grinding medium, deionized water as the grinding dispersant, use the ball mill to run alternately forward and reverse, and grind for 48h to obtain a mixed powder; dry the powder Passing through a 100-mesh sieve and pre-firing to obtain a dielectric energy storage cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com