Method for preparing diamond based on graphite under low pressure

A diamond and graphite technology, which is applied in the field of preparing diamond based on graphite under low pressure, can solve the problems of difficult high-quality uniform films, reduced film purity, and low deposition rate, and achieves the effects of simple process, low equipment requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

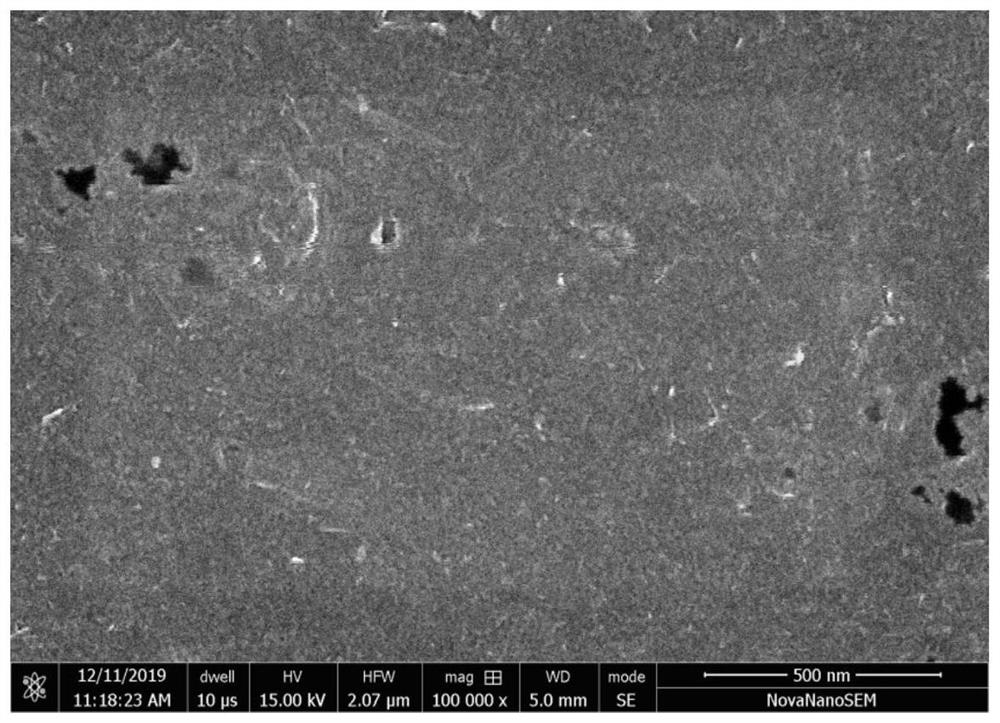

[0072] (1) Grind the graphite sheet (sequentially with 2000-mesh and 4000-mesh sandpaper), polish (polish with polishing flannel), ultrasonically clean in ethanol (140W ultrasonic for 15 minutes), clean with deionized water, dry (nitrogen gun blows) dry) to obtain a pretreated graphite sheet; the above pretreatment is to obtain a graphite sheet with a smooth and clean surface, which is wrapped with lens tissue after drying.

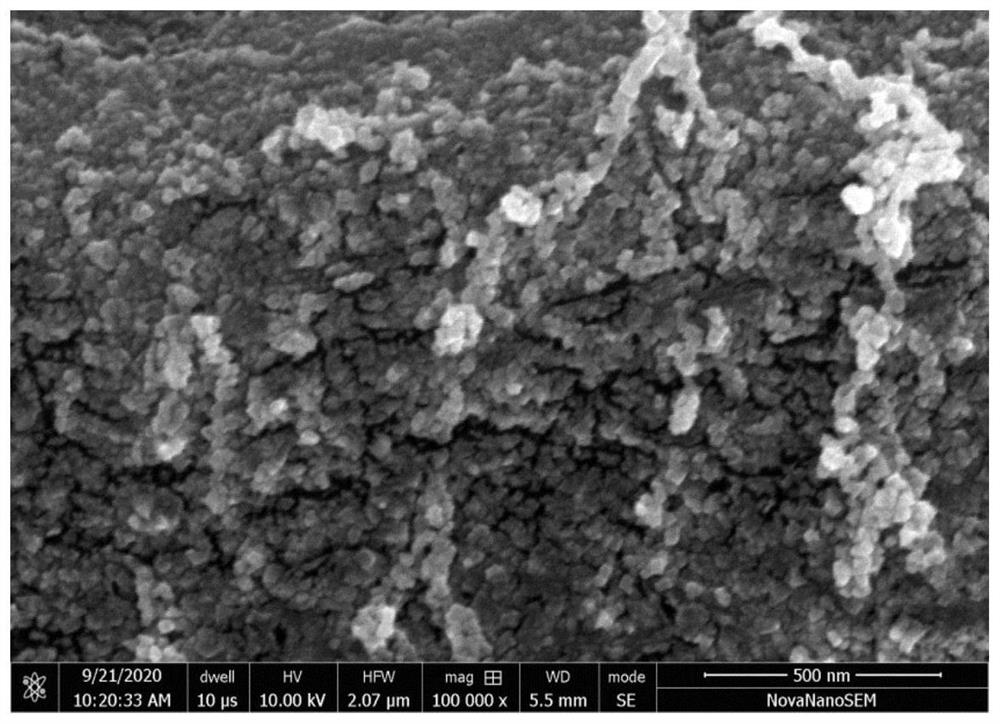

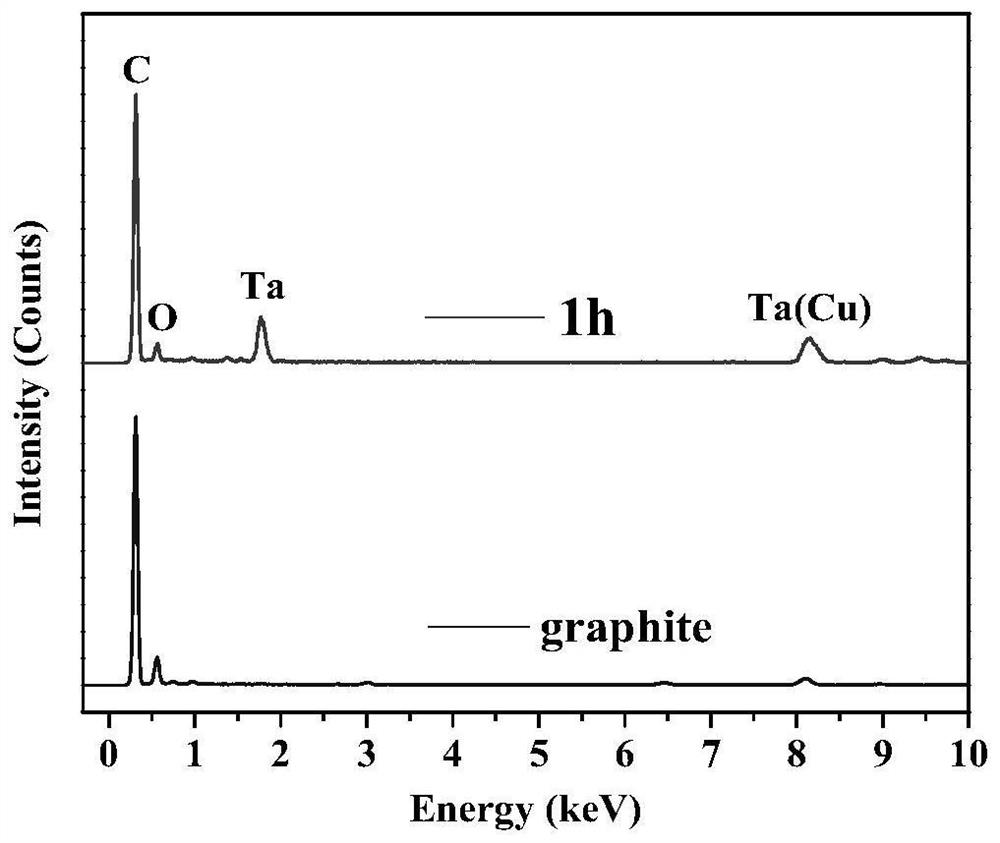

[0073] (2) The tantalum wire is installed 5mm away from the sample surface, the carbonization gas source is hydrogen and acetone, and the acetone is brought into the reaction chamber in the form of bubbling with hydrogen, the flow rate of the pure hydrogen is 200sccm, and the flow rate of the acetone is 80sccm ; 7V carbonization for 8 minutes, 12V carbonization for 7 minutes, 15V carbonization for 3 minutes, the total carbonization time is 18min, and the carbonization pressure is controlled to 5.7kPa. After the carbonization is completed, the power is rapi...

Embodiment 2

[0091] (1) Grind the graphite sheet (sequentially with 2000-mesh and 4000-mesh sandpaper), polish (polish with polishing flannel), ultrasonically clean in ethanol (140W ultrasonic for 15 minutes), clean with deionized water, dry (nitrogen gun blows) dry) to obtain a pretreated graphite sheet; the above pretreatment is to obtain a graphite sheet with a smooth and clean surface, which is wrapped with lens tissue after drying.

[0092] (2) The tantalum wire is installed 5mm away from the sample surface, the carbonization gas source is hydrogen and acetone, and the acetone is brought into the reaction chamber in the form of bubbling with hydrogen, the flow rate of the pure hydrogen is 200sccm, and the flow rate of the acetone is 80sccm ; 7V carbonization for 10min, 12V carbonization for 10min, 15V carbonization for 5min, the total carbonization time is 25min, the control carbonization pressure is 5.7kPa, after the carbonization is completed, the power is rapidly reduced to 0 in a h...

Embodiment 3

[0102] (1) Grind the graphite sheet (sequentially with 2000-mesh and 4000-mesh sandpaper), polish (polish with polishing flannel), ultrasonically clean in ethanol (140W ultrasonic for 15 minutes), clean with deionized water, dry (nitrogen gun blows) dry) to obtain a pretreated graphite sheet; the above pretreatment is to obtain a graphite sheet with a smooth and clean surface, which is wrapped with lens tissue after drying.

[0103] (2) The tantalum wire is tooled by means of double helical wire. The tantalum wire is 18mm away from the surface of the sample, and the carbonization time is 0min.

[0104] (3) Put the pretreated graphite sheet described in step (1) into the hot filament chemical vapor deposition (HFCVD) equipment described in step (2) as a substrate, and feed hydrogen with a flow rate of 100sccm and a power of 400W , control the air pressure to 3.5kPa, after 0.5h, reduce the power to 0 at a speed of 1V / min in a hydrogen atmosphere, and complete the first HFCVD tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com