Aerated block carrying device for building engineering construction

A technology for construction engineering and handling devices, which is applied in the field of handling tools, can solve the problems of large volume of aerated blocks, low handling efficiency, time-consuming and laborious loading and unloading, etc., and achieves the advantages of easy adjustment, convenient loading and unloading, and improved handling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

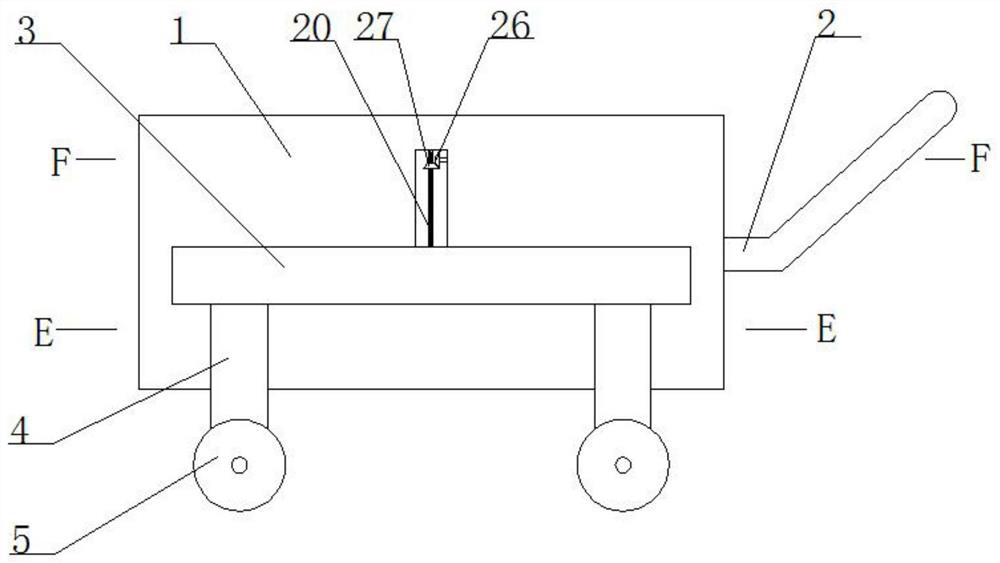

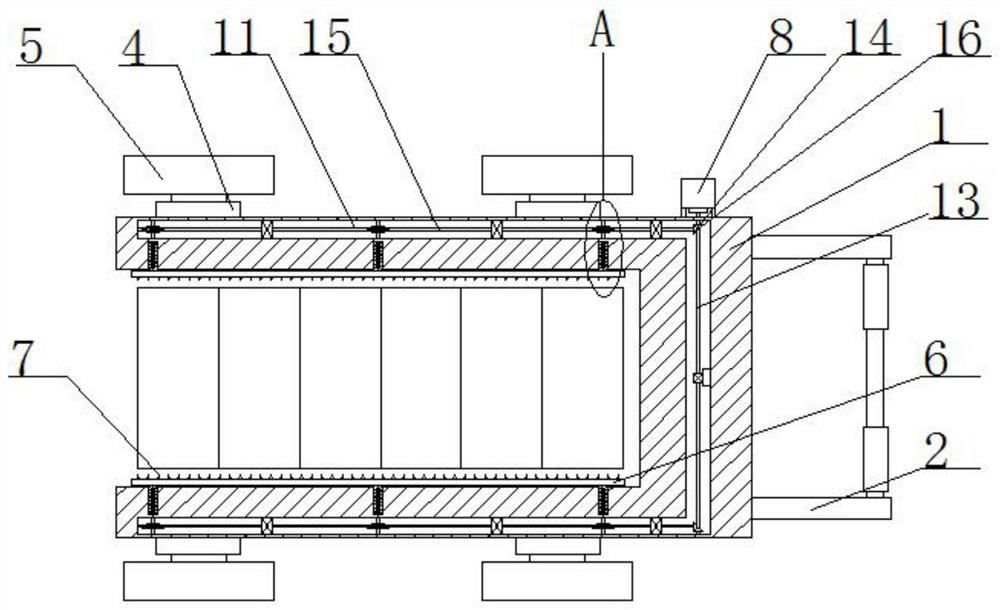

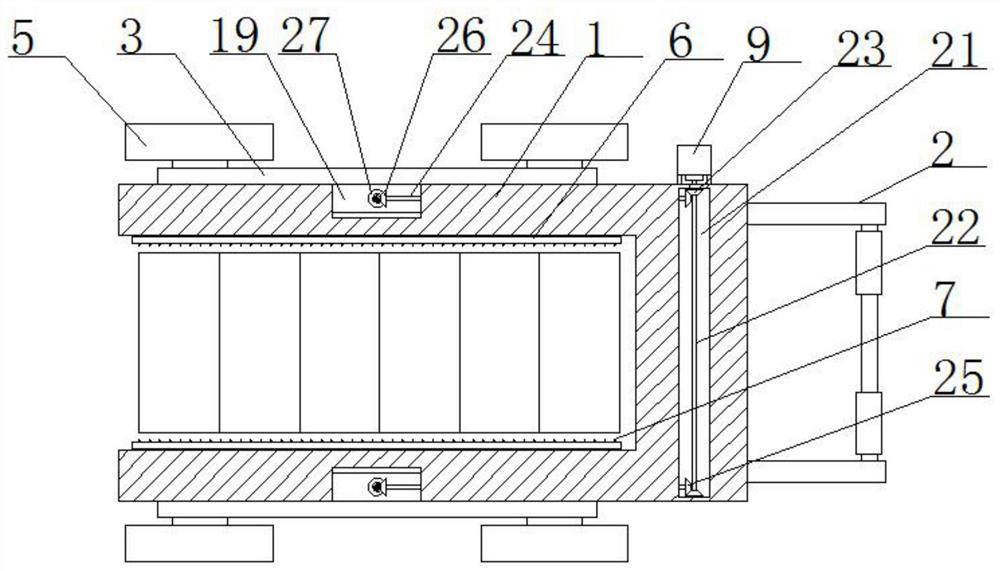

Embodiment 1

[0027] refer to Figure 1-5 , an air-entraining block handling device for building engineering construction, comprising a transport frame 1, a push rod 2 is fixedly connected to the transport frame 1, and lifting plates 3 are slidably installed on both sides of the transport frame 1, and the two lift The bottom of the plate 3 is fixedly connected with two fixed plates 4 by welding, the four fixed plates 4 are all provided with wheels 5, and the inner walls on both sides of the transport frame 1 are provided with a plurality of extrusion mechanisms, and many on both sides. Each of the extrusion mechanisms is fixedly connected to the same clamping plate 6 by welding, a plurality of extrusion teeth 7 are provided on both clamping plates 6, and a first motor 8 is fixedly installed on one side of the carrier frame 1 by bolts. , the first motor 8 is matched with the extrusion mechanism, and one side of the carrier frame 1 is fixedly installed with a second motor 9 through bolts, and...

Embodiment 2

[0037] The difference from the first embodiment is that it includes a transport vehicle frame 1, on which a push rod 2 is fixedly connected, and two anti-skid rubber sleeves are set on the push rod 2, and both sides of the transport vehicle frame 1 slide. Lifting plates 3 are installed, two fixing plates 4 are fixedly connected to the bottoms of the two lifting plates 3, wheels 5 are arranged on the four fixing plates 4, and a plurality of extruders are arranged on the inner walls of both sides of the transport frame 1. The same clamping plate 6 is fixedly connected to the multiple extrusion mechanisms on both sides, and a plurality of extrusion teeth 7 are arranged on the two clamping plates 6. One side of the carrier frame 1 is fixedly installed with a A motor 8 , the first motor 8 is matched with the extrusion mechanism, and a second motor 9 is fixedly installed on one side of the carrier frame 1 , and the second motor 9 is matched with the two lifting plates 3 .

[0038] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com