Conductive particle indentation detection equipment

A detection equipment and technology of conductive particles, applied in the field of optical detection, can solve the problems of poor quality consistency, difficult to control product quality stably, and high subjectivity of manual judgment, and achieve the effect of strong consistency, accurate detection effect and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

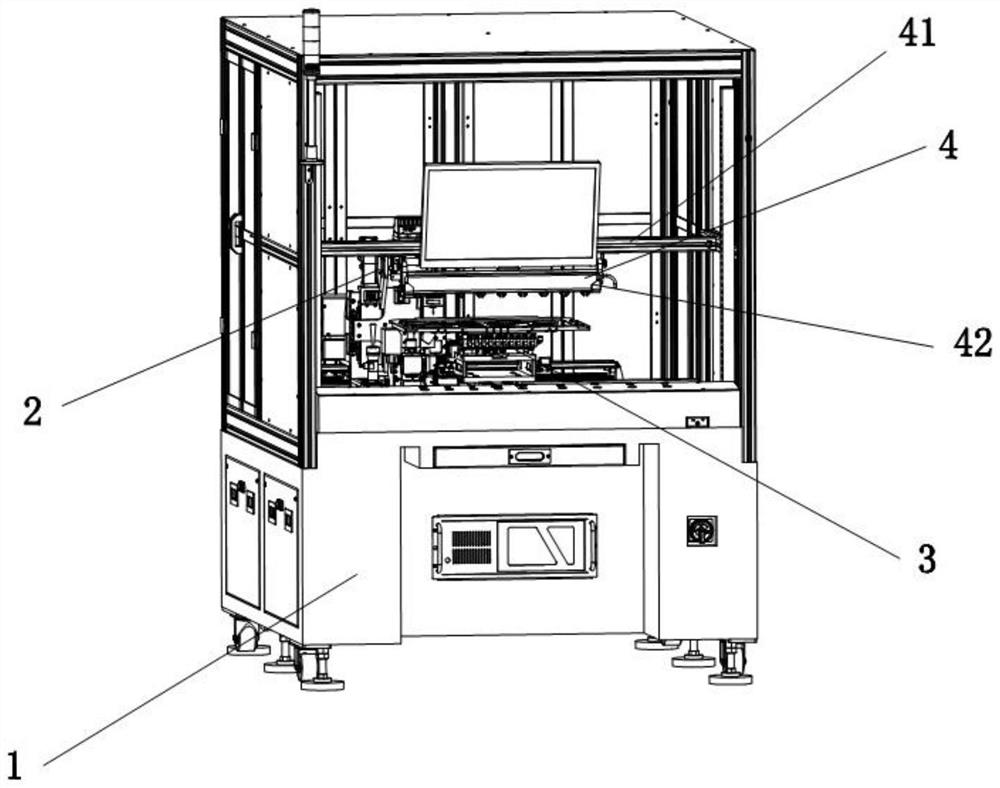

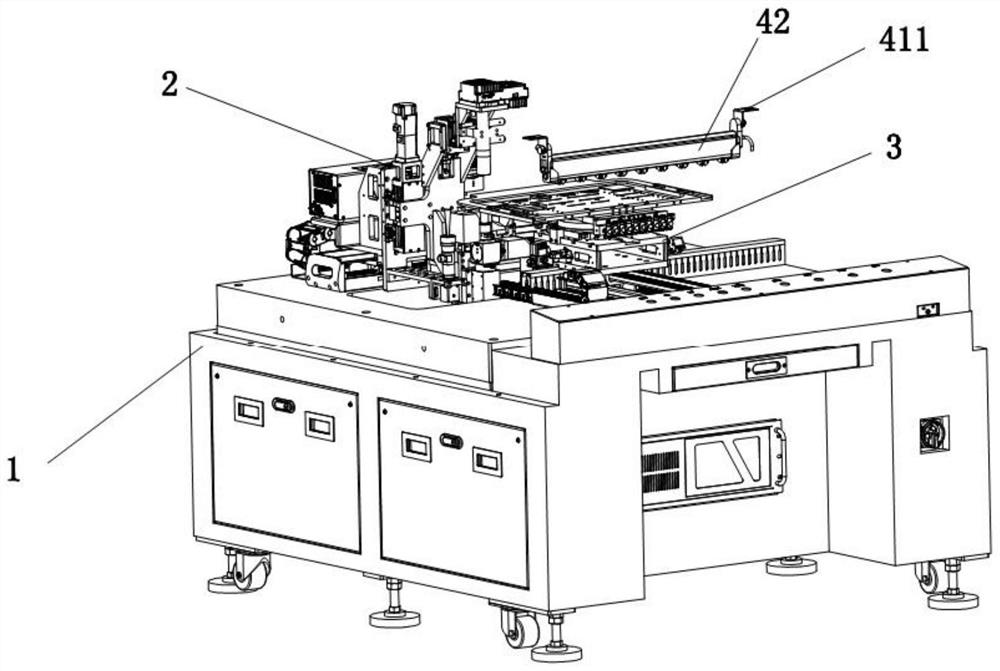

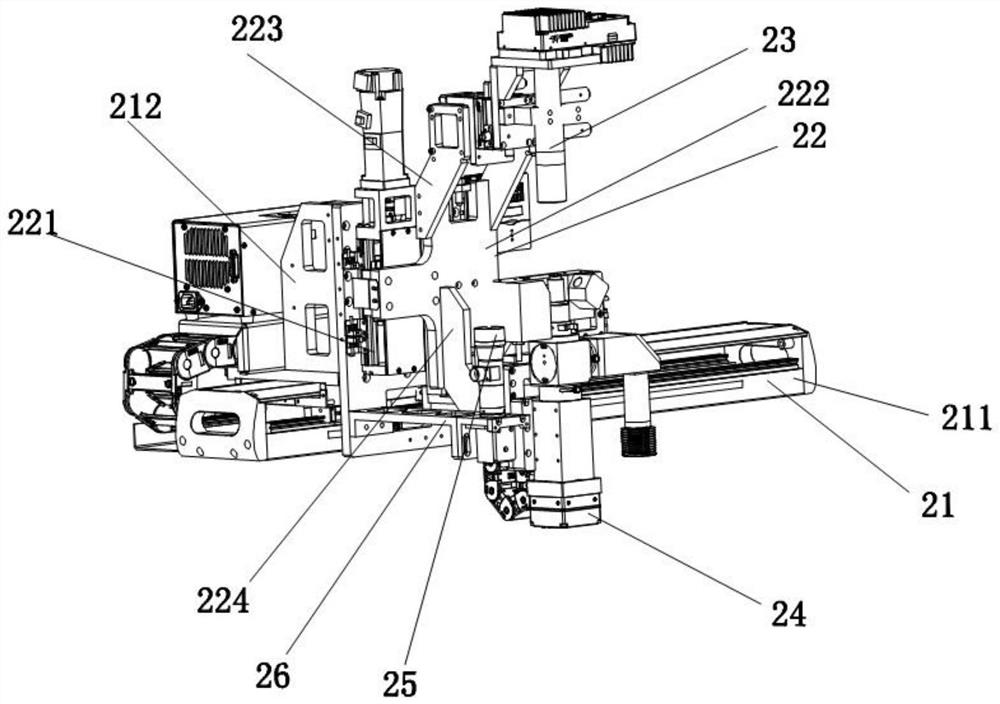

[0027] Cooperate Figure 1 to Figure 8 As shown, the present invention discloses a conductive particle indentation detection device, including a base 1, a detection mechanism 2 and a inspection mechanism 3. The detection mechanism 2 includes a line scan drive assembly 21, a camera stage 22, an offset detection assembly 23 and The particle detection component 24, the offset detection component 23 and the particle detection component 24 are respectively disposed on the upper side and the lower side of the camera stage 22 opposite to each other, and the line scan drive component 21 is used to drive the camera stage 22 to move along the detection direction to perform line scan detection , the feeding component 3 is used to transport the sample to be tested between the deviation detection component 23 and the particle detection component 24 . The offset detection component 23 is used to detect the offset status of the marks of the LCD screen, and the particle detection component 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com