Preparation method of true triaxial sample for reflecting occurrence characteristics of weak intercalated rock mass

A weak interlayer and sample preparation technology, applied in the field of geotechnical engineering, can solve the problems of uneven force, single function, high energy consumption, etc., and achieve the effects of multiple functions, energy saving, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

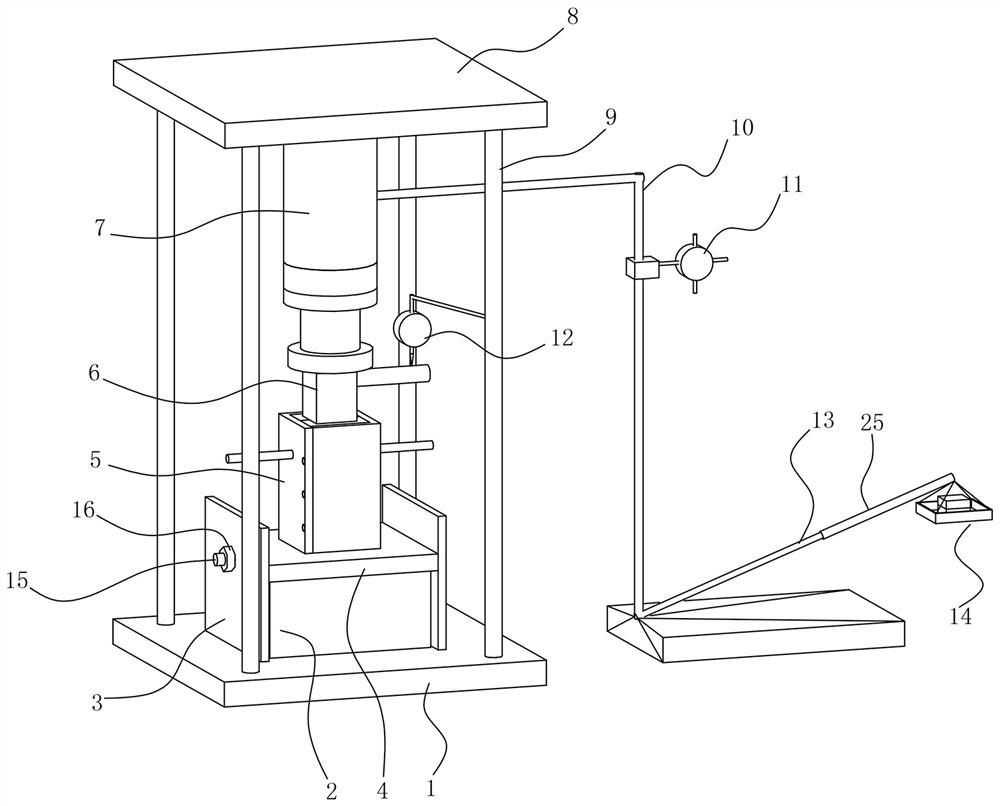

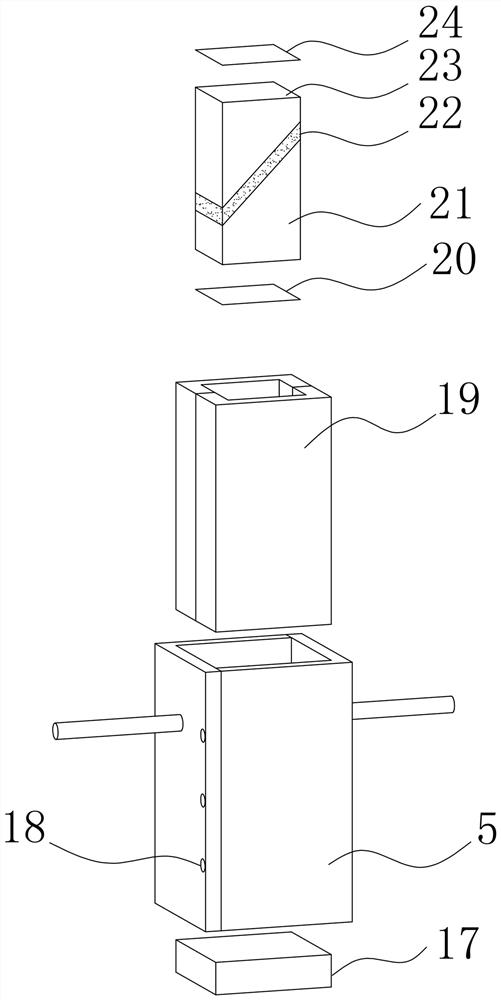

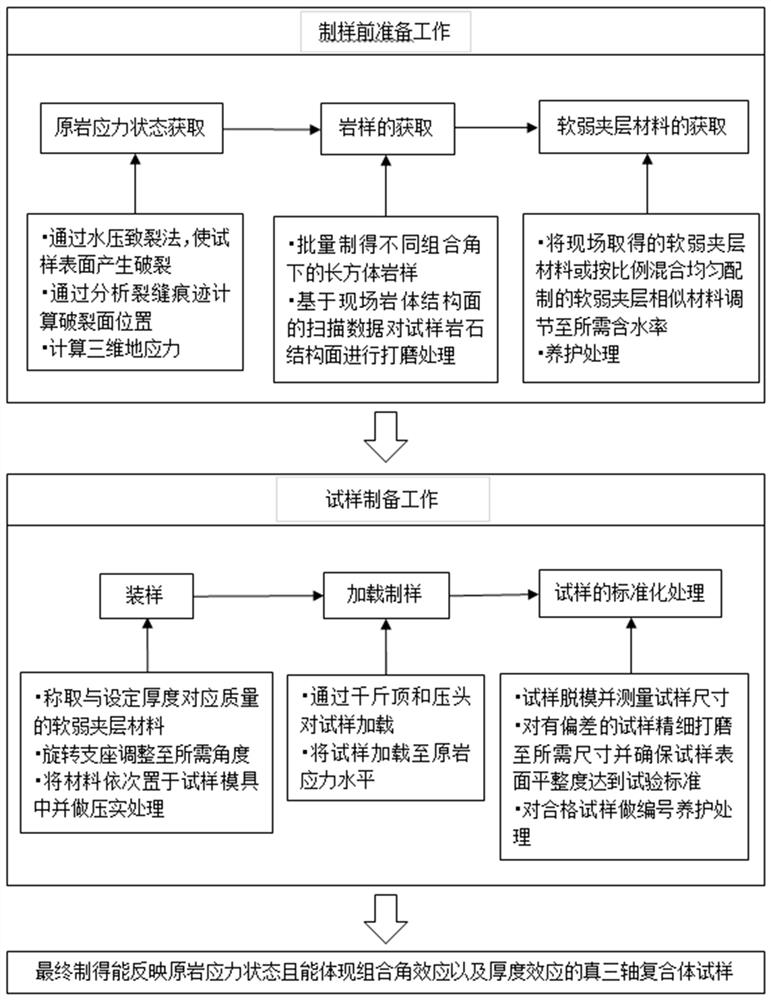

[0043] An embodiment of a true triaxial sample preparation method reflecting the occurrence characteristics of rock mass containing weak interlayers, such as Figure 1-2 shown, including the following steps:

[0044] Step 1. Obtain the stress state of the original rock

[0045] Using the hydraulic fracturing method, the sample is fractured through the fracturing test, and by analyzing the crack traces, the position of the fracture surface, that is, the direction of the maximum principal stress, is used to calculate the three-dimensional in-situ stress, the calculation method of the three-dimensional in-situ stress It is the prior art, and will not be repeated here;

[0046] Step 2. Acquisition of rock samples and weak interlayer materials

[0047] Equally spaced small holes are drilled along the different inclination lines of the center point of the rock sample and then split, and cuboid rock samples with different combination angles are obtained in batches, and then the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com