Integrated servo electric pinch valve

A pinch valve, integrated technology, applied in the direction of diaphragm valve, valve device, valve details, etc., can solve the problems that the valve cannot be dynamically adjusted, the clamping force cannot be adjusted, the open-loop control of the pinch valve, etc., and the replacement of valves can be saved time and cost, various control methods, and adjustable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

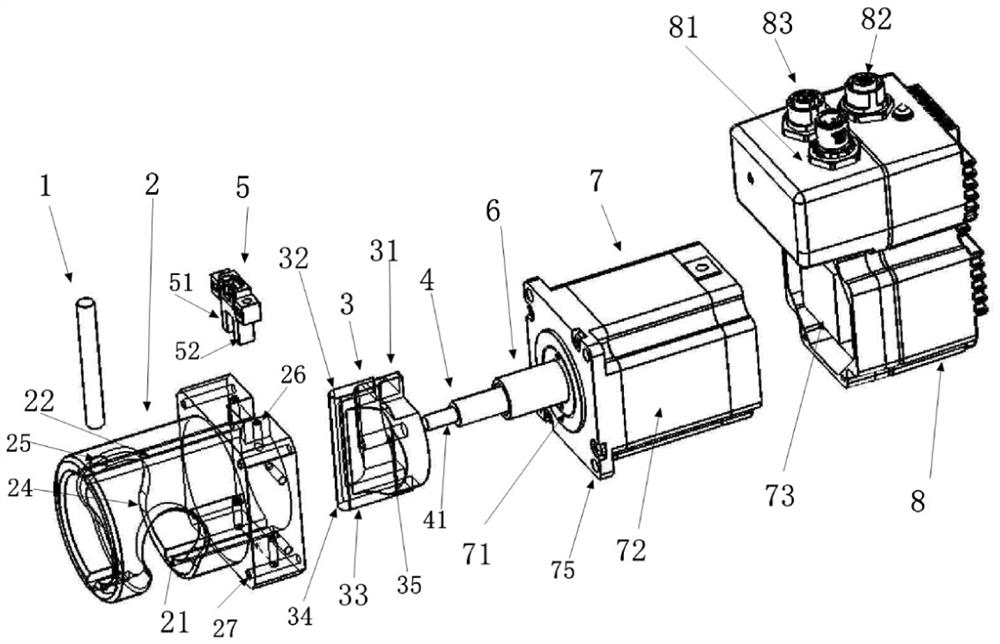

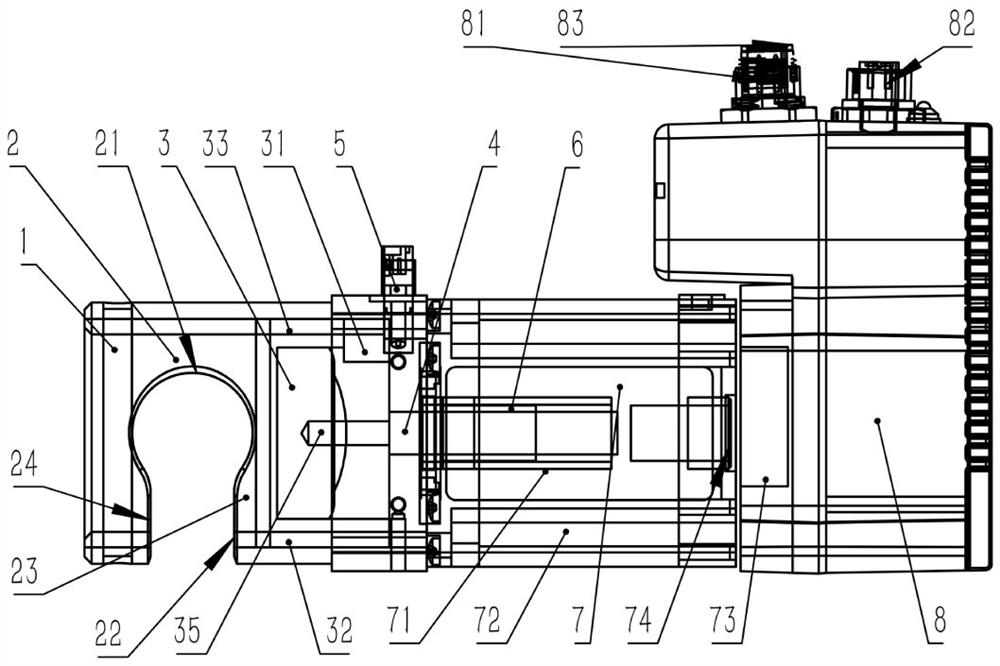

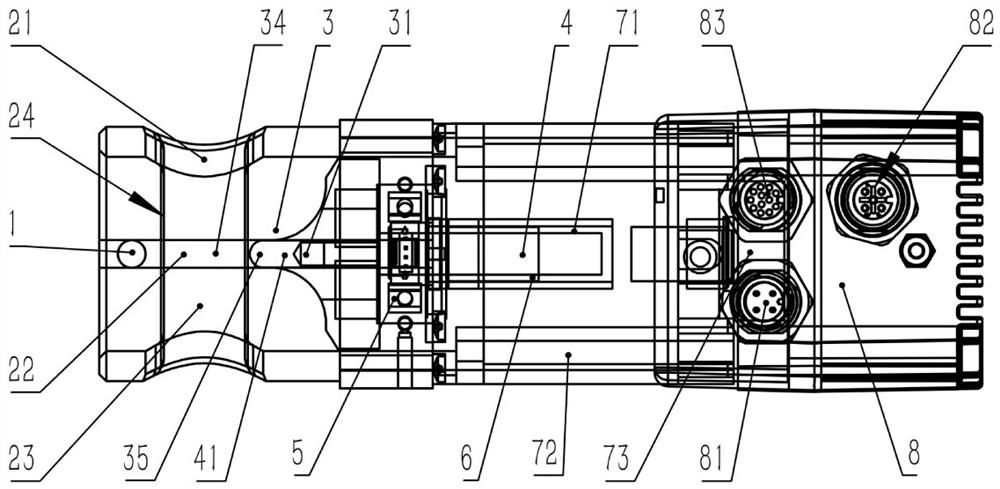

[0058] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the present application and are connected with the present invention. Figure 4 The purpose is to illustrate the principles of the present invention and not to limit the scope of the present invention.

[0059] like Figures 1~4 As shown, an integrated servo electric pinch valve provided by the present invention includes a bar 1, a valve body 2, a pressure head 3, a screw 4, a sensor 5, a motor 7, an encoder 73, and a driver 8; the valve The body 2 includes 21 a hose clamping part, a guide groove 22, a cavity 23, a round pipe pressure inlet 24, a positioning hole 25 for a rail, a sensor fixing hole 26 and a valve body fixing screw hole 27; the pressure head 3 includes a pressure head The sensor block 31, the indenter key 32, the indenter key 33, the front end arc surface 34 of the indenter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com