Digital printing method for tatting acetic acid printing

A digital printing and printing technology, applied in dyeing, textile and papermaking, etc., can solve the problems of weak high temperature resistance of acetate fiber, difficult to meet the appearance of the fabric, hardening of the acetate fabric, etc., to achieve good color development effect, not easy to fade naturally , The effect of not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

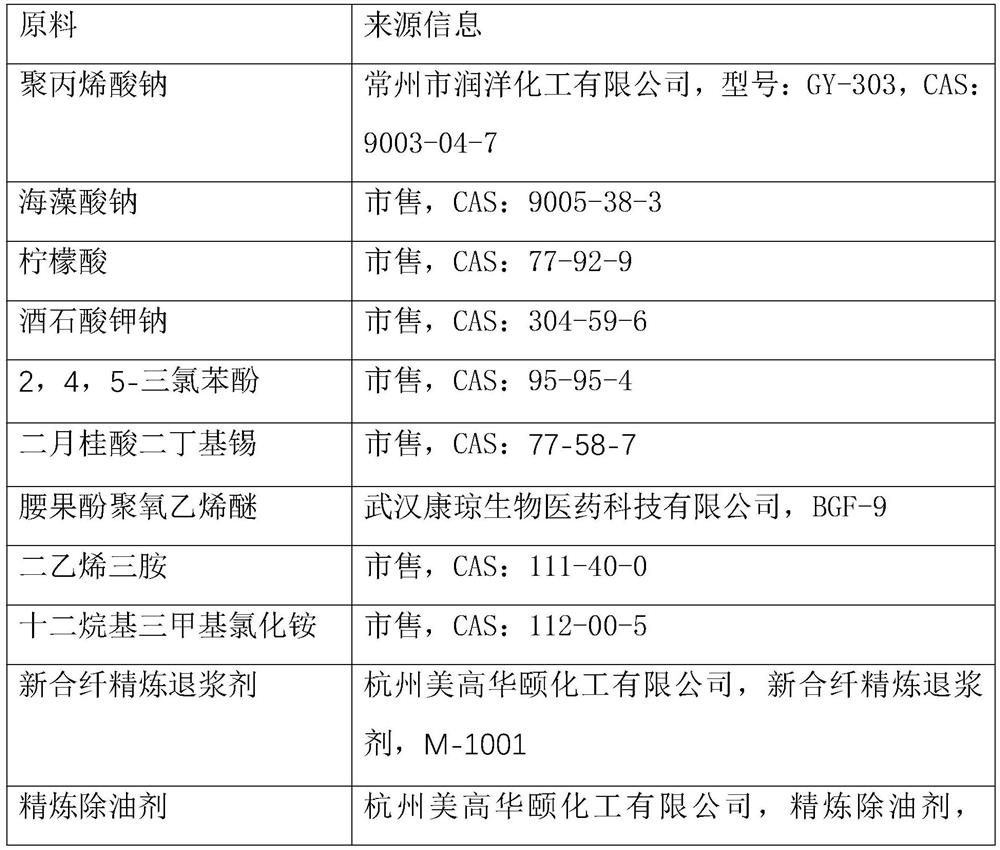

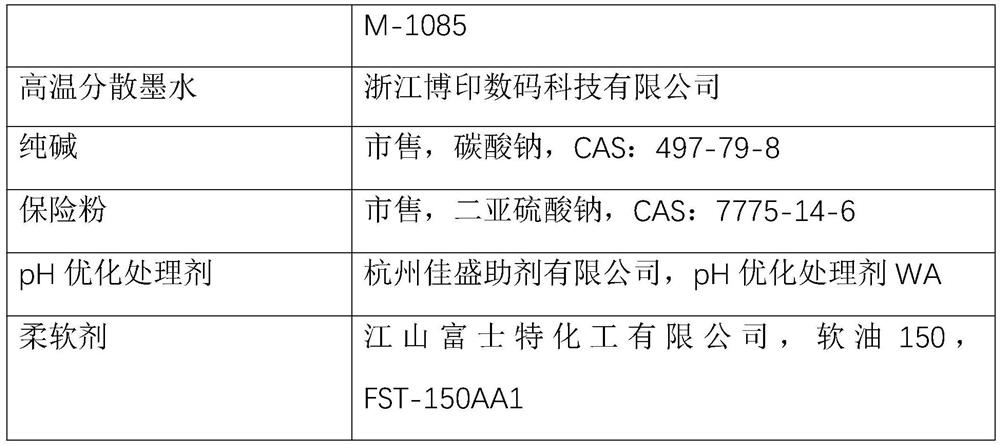

[0061] A sizing slurry comprising the following components:

[0062] Thickener, dye accelerator, surfactant, water.

[0063] Among them, the thickener is a compound of sodium polyacrylate and sodium alginate, and the mass ratio of sodium polyacrylate and sodium alginate is 1:1.

[0064] Among them, the dye accelerator is the compound of citric acid, potassium sodium tartrate, 2,4,5-trichlorophenol, dibutyltin dilaurate, cardanol polyoxyethylene ether, citric acid, potassium sodium tartrate, 2,4, The mass ratio of 5-trichlorophenol, dibutyltin dilaurate and cardanol polyoxyethylene ether is 1:3:1:2:3.

[0065] Wherein, the surfactant is a compound of diethylenetriamine and dodecyltrimethylammonium chloride, and the mass ratio of diethylenetriamine and dodecyltrimethylammonium chloride is 1:4.

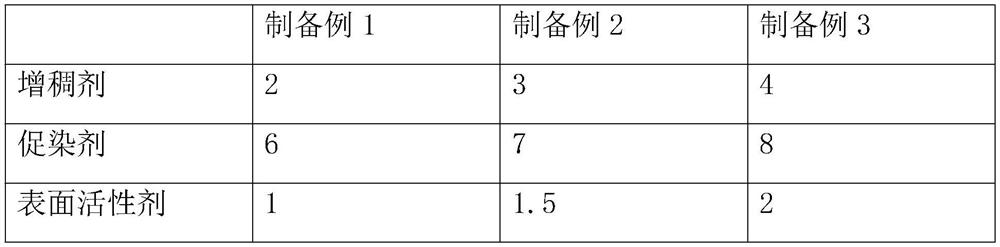

[0066] In Preparation Examples 1-3, the specific input amount (unit kg) of each component is shown in Table 2.

[0067] Table 2

[0068]

[0069]

[0070] The preparation metho...

Embodiment 1

[0088] A digital printing method for woven acetate printing, comprising the following steps:

[0089] Step 1), pre-treatment, washing the fabric, including:

[0090] Put clean water in the washing machine, add new synthetic fiber refining desizing agent and refining degreaser to the clean water, add 0.5g new synthetic fiber refining desizing agent and 0.5g refining degreaser to each liter of clean water, and then put the fabric into In the washing machine, wash in the washing machine at 90°C for 30 minutes, and take out the fabric.

[0091] Step 2), pre-type, specifically including:

[0092] The pre-treated fabric is transported to the setting machine for pre-setting. The temperature of the setting machine is 160°C, and the speed of the setting machine is 35m / min. Negative overfeeding or positive overfeeding can be adjusted as needed. In this embodiment, no overfeeding adjustment is performed. . Overfeed range is -2% to 20% of vehicle speed.

[0093] Step 3), sizing, apply...

Embodiment 2

[0107] A digital printing method of woven acetate printing, compared with embodiment 1, the difference is only:

[0108] In step 1), the fabric is put into the washing machine, washed in the washing machine at 130° C. for 20 minutes, and the fabric is taken out.

[0109] In step 2), the pre-treated fabric is transported to a setting machine for pre-setting, the temperature of the setting machine is 180°C, and the speed of the setting machine is 35 m / min.

[0110] In step 4), the dried fabric is transported into a vertical steamer, and steamed at 130° C. for 35min.

[0111] In step 5-1), the steamed cloth is transported to the cloth washing machine, the cloth washing machine is filled with clean water at room temperature, and the cloth washing machine is started for cleaning, while maintaining water injection, so that the water flow in the cloth washing machine overflows, and the water injection speed is 1L / min, overflow cleaning for 12min.

[0112] In step 5-2), stop the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com