High-barrier-property flame-retardant backboard and preparation method thereof

A high-barrier, backplane technology, used in climate sustainability, polymer adhesive additives, non-polymer adhesive additives, etc. It can reduce the flame retardant effect, improve the water vapor barrier effect, and improve the compatibility effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

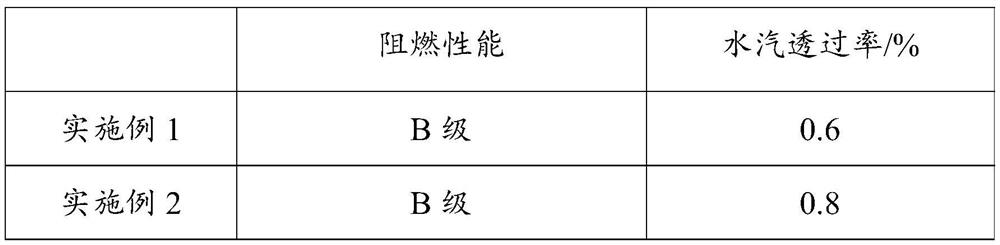

Examples

Embodiment 1

[0066] This embodiment provides a high-barrier flame-retardant backplane, the structure of which includes: a structural layer and an adhesive layer, the adhesive layer is located at the bottom of the backplane; the structural layer is located at the top of the backplane;

[0067] The thickness of the adhesive layer is 100 μm;

[0068] The thickness of the structural layer is 300 μm.

[0069] The raw materials of the adhesive layer, in parts by weight, include the following components: 12 parts of polyethylene wax, 2 parts of antioxidants, 2 parts of light stabilizers, 15 parts of auxiliary agents, and 110 parts of polyethylene.

[0070] The polyethylene wax had a weight-average molecular weight of 3000, a viscosity of 550 mPa·s, 220° C., and was purchased from Ningbo Weiye Plastic & Chemical Co., Ltd.

[0071] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168. The weight ratio of the antioxidant 1010 to the antioxidant 168 is 1:1.

[0072] The light stabi...

Embodiment 2

[0098] The specific implementation of Example 2 is the same as that of Example 1; the difference is that the raw materials of the structural layer described in Example 2, in parts by weight, include the following components: 100 parts of polyolefin, 5 parts of flame retardant, and 20 parts of solid filler parts, 2 parts of curing agent, 15 parts of auxiliary agent. The flame retardant is a modified phosphorus-nitrogen composite material.

Embodiment 3

[0100] The specific implementation of Example 3 is the same as that of Example 1; the difference is that the raw materials of the adhesive layer described in Example 3, in parts by weight, include the following components: 15 parts of polyethylene wax, 3 parts of antioxidant, 3 parts of stabilizer, 20 parts of auxiliary, and 120 parts of polyethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com