Embedded sieve plate state monitoring device and monitoring method thereof

A condition monitoring device and embedded technology, applied in measuring devices, chemical instruments and methods, sieves, etc., can solve the problems of waste of sieves, only regular inspections, and insufficient troubleshooting, so as to reduce personal safety risks, The effect of avoiding production accidents and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

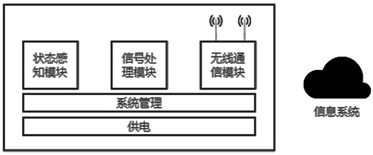

[0045] like figure 1 As shown, the embedded sieve plate state monitoring device includes a power supply module for providing power supply, and also includes a state sensing module, the state sensing module is connected with a signal processing module, and the signal processing module is connected with a background management system through a communication module. , the background management system is connected with sieve plate operation equipment and alarm equipment;

[0046] The state sensing module is used to collect the operating state data of the sieve plate;

[0047] The signal processing module is used for analyzing and processing the collected operating state data of the sieve plate, and judging the fixing condition of the sieve plate;

[0048] The background management system is used for data traces and sending of relevant instructions;

[0049] The communication module is used to realize the communication between the signal processing module and the background manag...

Embodiment 2

[0056] A monitoring method for an embedded sieve plate state monitoring device applied to Embodiment 1, comprising the following steps:

[0057] Step 1: signal collection; in the step 1, the collected information includes triaxial acceleration and temperature.

[0058] Step 2: Use the time domain threshold detection algorithm, frequency domain power spectral density (PSD) analysis, and combine the adaptive filter algorithm to carry out adaptive evolution to determine whether the sieve plate is loose;

[0059] The second step includes the following sub-steps:

[0060] 1-1: Calculate time domain eigenvalues , its calculation formula is:

[0061] in is the peak instantaneous acceleration, is the effective value of acceleration, which reflects the degree to which the maximum amplitude deviates from the vibration center value, and the characteristic value will increase significantly when the sieve plate is loose;

[0062] 1-2: Time domain eigenvalues Corresponding contras...

Embodiment 3

[0079] On the basis of Example 1 and Example 2

[0080] For example, in actual operation, the effective value of the acceleration of the vibrating screen About 2.01g (g =9.8m / s²), the peak instantaneous acceleration during its normal operation is 2.8g (g =9.8m / s²), then calculate the time domain eigenvalue according to the formula is 1.393, calculated by the least mean square algorithm =1.775, then Srp=1.42, at this time Rp(1.393)<Srp(0.8*1.775), the device is running normally.

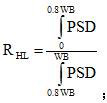

[0081] The power spectral density of the sieve plate is collected by a power spectral density measuring instrument, and the high / low frequency parts are integrated respectively with 80% of the frequency band broadband (WB) as the boundary, and the ratio is obtained. =352.66, output value after LMS adaptive filter =467.11. (352.66) (0.8*467.11), which means that the sieve plate is in normal working condition. The above conclusions are consistent with the status of the field equipment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com