Preparation method of polyolefin hollow fiber membrane

A fiber membrane and polyolefin technology, applied in the field of membrane materials, can solve the problems of hollow fiber membrane membrane pore structure damage, hole collapse, long plasma penetration time of hollow fiber membrane, etc., to achieve high gas mass transfer rate, ensure integrity, The effect of great industrial practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

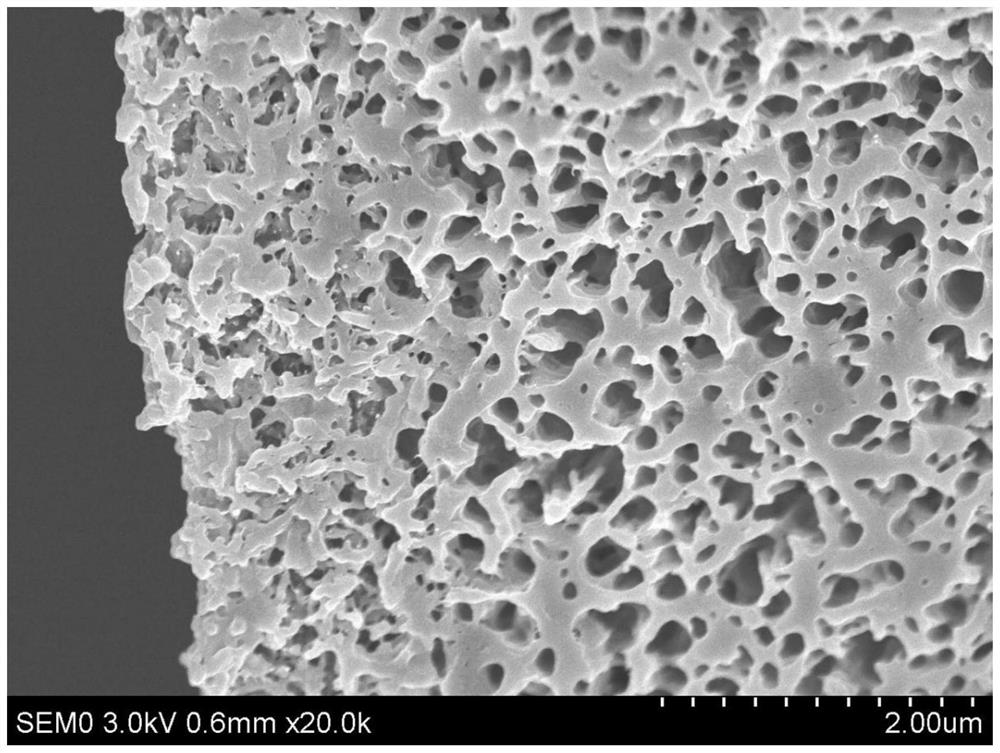

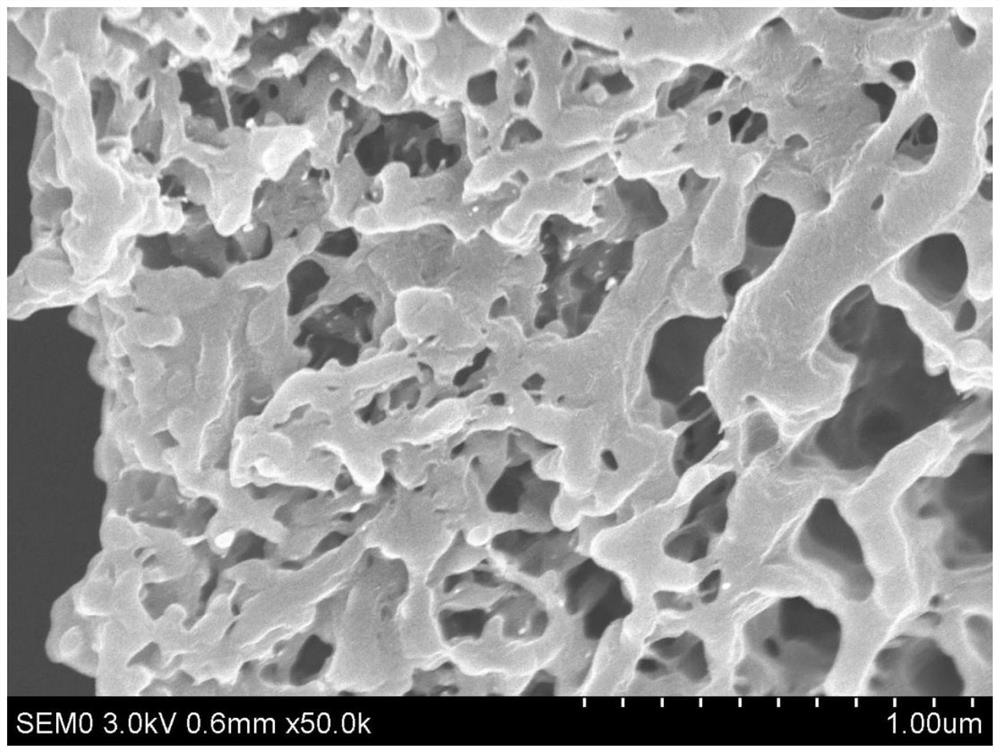

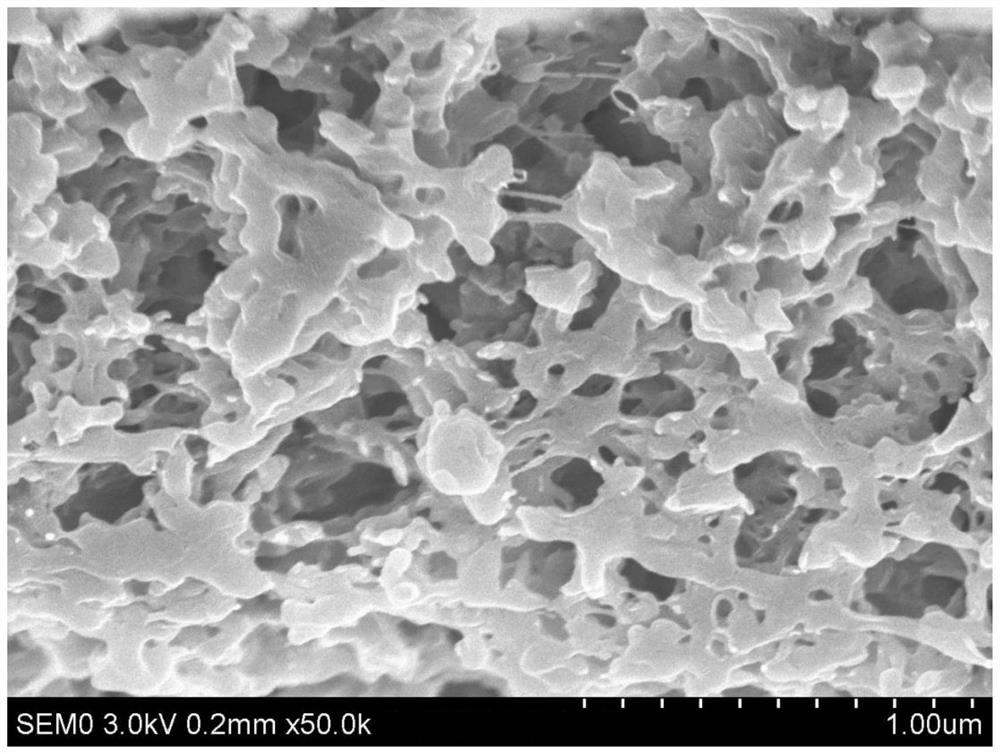

Image

Examples

Embodiment 1

[0054] A preparation method of polyolefin hollow fiber membrane, comprising the following steps:

[0055] Step 1: Add the solvent system consisting of 45wt% compound A and 15wt% compound B and 40wt% poly(4-methyl-1-pentene) into a twin-screw extruder and stir and knead at 240°C to obtain a homogenous solution. Phase casting liquid; wherein compound A is methyl-12-hydroxystearic acid, and compound B is dioctyl adipate;

[0056] Step 2: extruding the casting liquid from a die head with a temperature of 220°C to obtain a molded product with an inner surface and an outer surface;

[0057] Step 3: Immerse the molded product in a cooling liquid for phase separation and solidification, wherein the cooling liquid is methyl-12-hydroxystearic acid, the cooling liquid temperature is 35°C, and the phase separation solidification time is 70ms;

[0058] Step 4: then use methyl-12-hydroxystearic acid as a quenching liquid to quench the molded product, the quenching temperature is 60°C, the ...

Embodiment 2

[0063] A preparation method of polyolefin hollow fiber membrane, comprising the following steps:

[0064] Step 1: Add the solvent system consisting of 41wt% compound A and 24wt% compound B and 35wt% poly(4-methyl-1-pentene) into a twin-screw extruder and stir and knead at 230°C to obtain a homogenous solution. Phase casting liquid; wherein compound A is dibutyl sebacate, and compound B is rapeseed oil;

[0065] Step 2: Extruding the casting liquid from a die head with a temperature of 215°C to obtain a molded product with an inner surface and an outer surface;

[0066] Step 3: The molded product is immersed in the cooling liquid for phase separation and solidification, wherein the cooling liquid is the solvent system (solvent system composed of 41wt% dibutyl sebate and 24wt% rapeseed oil) used in preparing the casting liquid, and the cooling liquid The temperature is 30°C, and the phase separation curing time is 60ms;

[0067] Step 4: then use the solvent system (solvent sys...

Embodiment 3

[0072] A preparation method of polyolefin hollow fiber membrane, comprising the following steps:

[0073] Step 1: Add a solvent system consisting of 38wt% compound A and 17wt% compound B and 45wt% polypropylene into a twin-screw extruder, stirring and kneading at 235°C to obtain a homogeneous casting liquid; wherein compound A is Dehydrated castor oil fatty acid, compound B is dimethyl phthalate;

[0074] Step 2: extruding the casting liquid from a die head with a temperature of 220°C to obtain a molded product with an inner surface and an outer surface;

[0075] Step 3: Immerse the molded product in a cooling liquid for phase separation solidification, wherein the cooling liquid is dehydrated castor oil fatty acid, the cooling liquid temperature is 45°C, and the phase separation solidification time is 80ms;

[0076] Step 4: then use dehydrated castor oil fatty acid as quenching liquid to quench the molded product, the quenching temperature is 75°C, the quenching time is 3h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com