Ceramic atomizing core structure and preparation method thereof

An atomizing core and ceramic technology, applied in the field of atomization structure of electronic atomizer, can solve the problems of insufficient atomization effect, limited atomization area, and taste not as good as cotton core, etc. The effect of uniform atomization flow and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

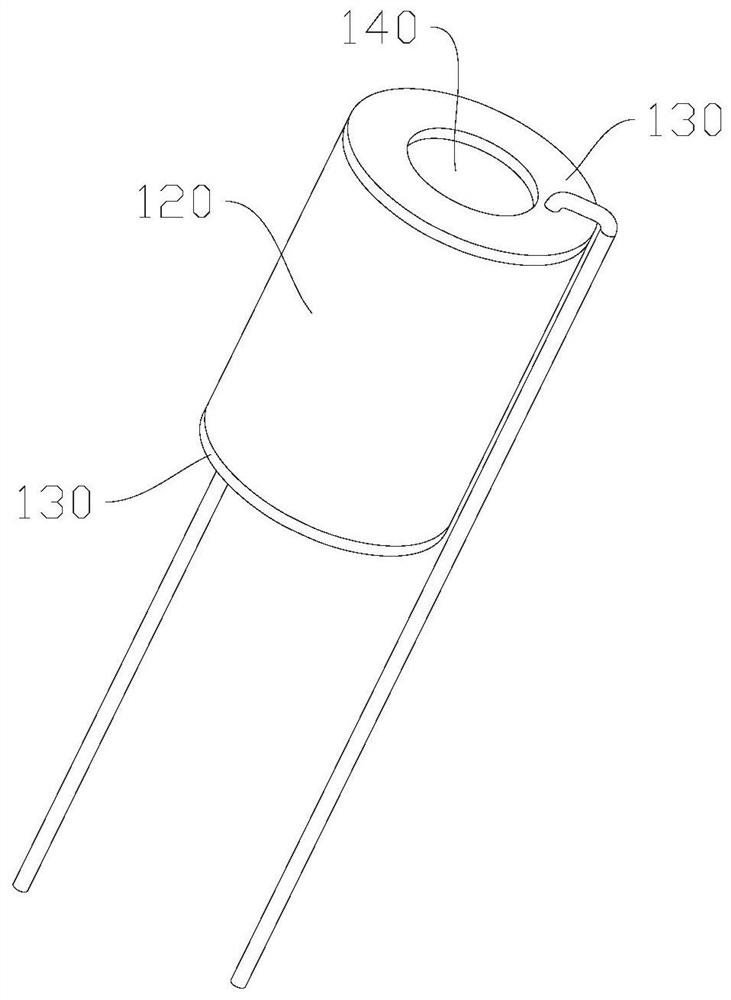

[0054] like Figure 1-Figure 4 As shown in the figure, the structure of the ceramic atomizing core is cylindrical. Specifically, an atomization channel 140 is formed in the middle of the cylindrical body. The cylindrical body is divided into an outer ring and an inner ring. It is made of oleoceramic 120 material, and electrode conductors 130 are attached to the end faces on both sides of the cylinder. The oil-conducting ceramic 120 sucks the atomized liquid contacted by the outer ring into the outer ring, and penetrates the atomized liquid into the conductive heating ceramic 110 through its porous nature. When the liquid contacts the heated conductive heating ceramic 110, it is atomized into oil mist, which flows from the atomization channel 140 in the middle of the cylindrical shape. The oil guiding area is large enough, and the whole surrounding can be effectively contacted with the atomized liquid. The direction of the air intake and the direction of the flue gas can be st...

Embodiment 2

[0056] like Figure 5-Figure 8 As shown, the structure of the ceramic atomizing core is in the shape of a boat, specifically, in a semicircle shape, one end of the semi-cylindrical plane is recessed inward to form an oil storage cavity 150, the inner ring of the semi-cylindrical is an oil-conducting ceramic 120, and the outer ring is a conductive heating ceramic 110. The conductive heating ceramic 110 is covered on the arc surface side of the oil conductive ceramic 120 , the electrode conductors 130 are attached to both ends of the conductive heating ceramic 110 , and the outer side of the conductive heating ceramic 110 is the atomization channel 140 . During the sucking process, the atomized liquid is injected into the oil storage cavity 150, and the atomized liquid evenly extends into the oil-conducting ceramics 120, and is transferred to the conductive heating ceramics 110 to be heated and atomized. The atomized atomization liquid flows along the atomization channel 140 out...

Embodiment 3

[0059] like Figure 9 and Figure 10 As shown in the figure, the structure of the ceramic atomizing core is in the shape of a block. Specifically, the oil-conducting ceramic 120 is in the shape of a square. One side of the oil-conducting ceramic 120 is grooved, the conductive heating ceramic 110 is arranged in the groove, and the electrode conductor 130 is arranged in the conductive On both sides of the heating ceramic 110 , the outer surface of the conductive heating ceramic 110 is an atomization channel 140 . The atomized liquid in the oil-conducting ceramic 120 penetrates into the conductive heating ceramic 110 , and the atomized liquid is heated to form an oil mist from the outer surface of the conductive heating ceramic 110 . It is suitable for the structure of the atomizer with a relatively flat shape.

[0060] The oil-conducting ceramic 120 can also be provided with a through groove, the through-groove is arranged through, the conductive heating ceramic 110 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com