Three-dimensional porous carbon composite material for lithium-sulfur battery and preparation method of three-dimensional porous carbon composite material

A carbon composite material, three-dimensional porous technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of complex experimental conditions, toxic raw materials, environmental pollution, etc., meet the experimental conditions and the preparation method is simple, good conductivity And chemical stability, the effect that is beneficial to transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

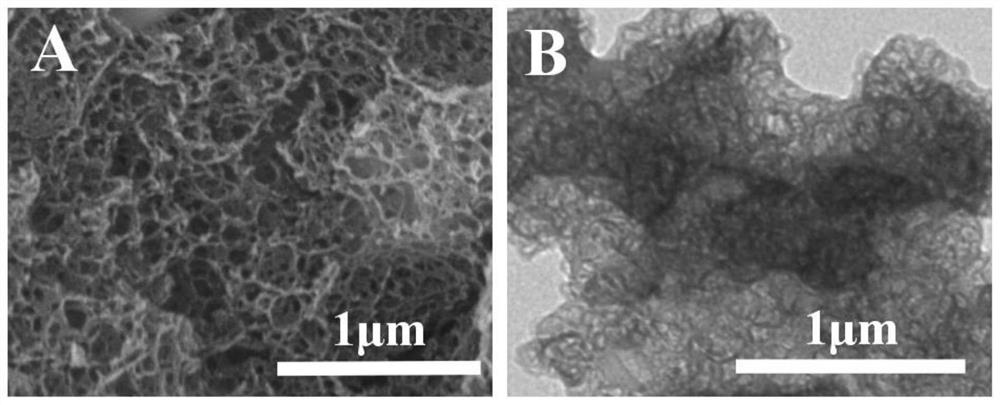

[0041] In the preparation method of the three-dimensional porous carbon composite material of the present invention, firstly, the polyacrylamide is dissolved in ultrapure water and becomes a gel under the action of magnetic stirring, and then the solution containing iron nitrate and nickel nitrate is slowly added dropwise to a In the gel, phytic acid and melamine are added to the mixture as phosphorus and nitrogen sources, and then under the action of high temperature, polyacrylamide will melt into a fluid, and iron nitrate and nickel nitrate will decompose to produce a large amount of gas. A large number of porous structures were formed when escaping from the molten polyacrylamide, and finally N, P co-doped 3D porous carbon composites were obtained.

[0042] The model of the material involved in the present invention and the source of purchase are described as follows:

[0043] Material name model source of purchase Polyacrylamide (PAM) Molecular weight: ...

Embodiment 1

[0045] In this embodiment, the preparation method of the three-dimensional porous carbon composite material includes the following steps:

[0046] (1) Under magnetic stirring at 280r / min, dissolve 0.142g of polyacrylamide in 120mL of ultrapure water, and stir for 60min until the solution forms a gel;

[0047] (2) under 450r / min magnetic stirring, 2mmol of ferric nitrate and 2mmol of nickel nitrate were added into 40mL of ultrapure water to dissolve, to form a solution containing ferric nitrate and nickel nitrate simultaneously, and then the solution containing ferric nitrate and nickel nitrate was added dropwise In the gel of step (1);

[0048] (3) 0.2mmol phytic acid and 7.5mmol melamine are added in the product of step (2) as phosphorus source and nitrogen source, and magnetic stirring 30min at 450r / min;

[0049] (4) Take the product of step (3), pour out the supernatant, put it in an oven, and dry it at 90°C for 10h;

[0050] (5) The powder obtained in step (4) is ground ...

Embodiment 2

[0060] In Example 2, the preparation method of the three-dimensional porous carbon composite material is basically the same as the method in Example 1, and the difference lies in step (2). Step (2) is to add 3mmol ferric nitrate and 3mmol nickel nitrate to 40mL ultrapure water respectively under 450r / min magnetic stirring to dissolve, form the solution containing ferric nitrate and nickel nitrate simultaneously, then the solution containing ferric nitrate and nickel nitrate is formed. Drop into the gel of step (1).

[0061] The properties of the material prepared in Example 2 are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com