Power station condenser cooling pipe steam flow excitation assessment method based on shell side flow field

A vapor flow excitation and condenser technology, which is used in data processing applications, complex mathematical operations, design optimization/simulation, etc., can solve the problem of uneven distribution of the flow field on the side of the condenser shell, failure and leakage of cooling pipes without considering and other problems to achieve the effect of avoiding steam flow excitation, improving accuracy and high engineering significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

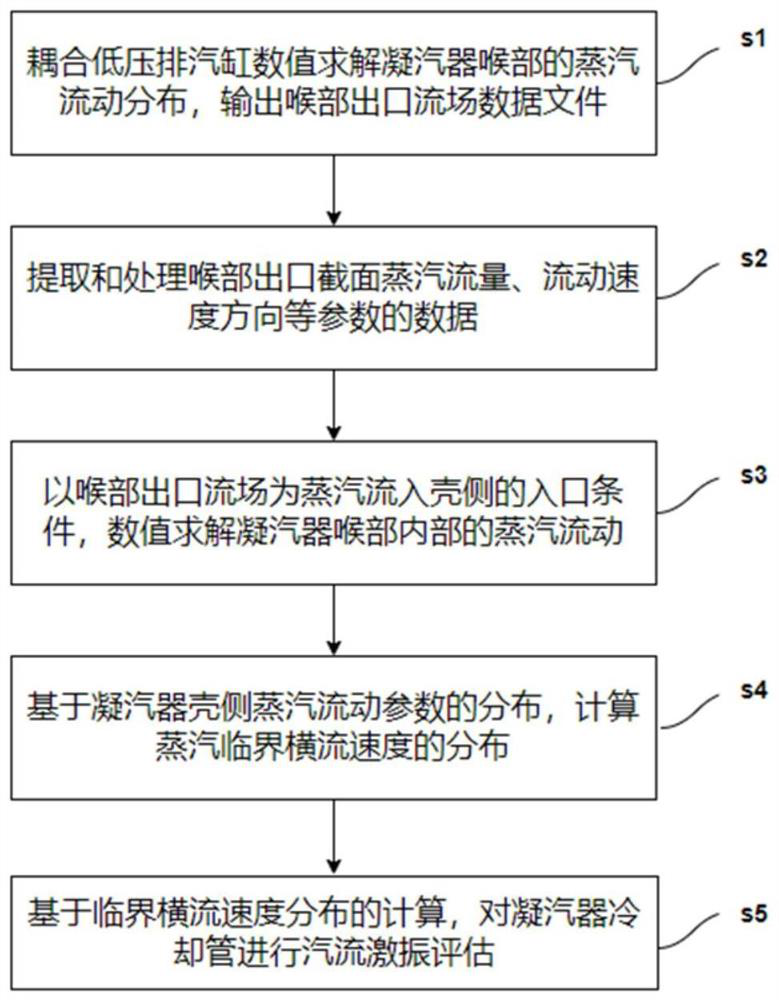

[0064] like figure 1 As shown, this embodiment provides a method for evaluating the vapor flow excitation of a cooling tube of a large condenser based on the shell-side flow field, which includes the following steps:

[0065] S1. Taking the solid model of the condenser throat of the coupled exhaust cylinder as the object, establish the motion equation of the steam at the condenser throat according to the laws of mass conservation and momentum conservation, and use flow heat transfer numerical calculation software (such as Fluent, CFX, etc.) to solve The specific distribution of the steam flow inside the throat of the condenser is obtained, which is as follows:

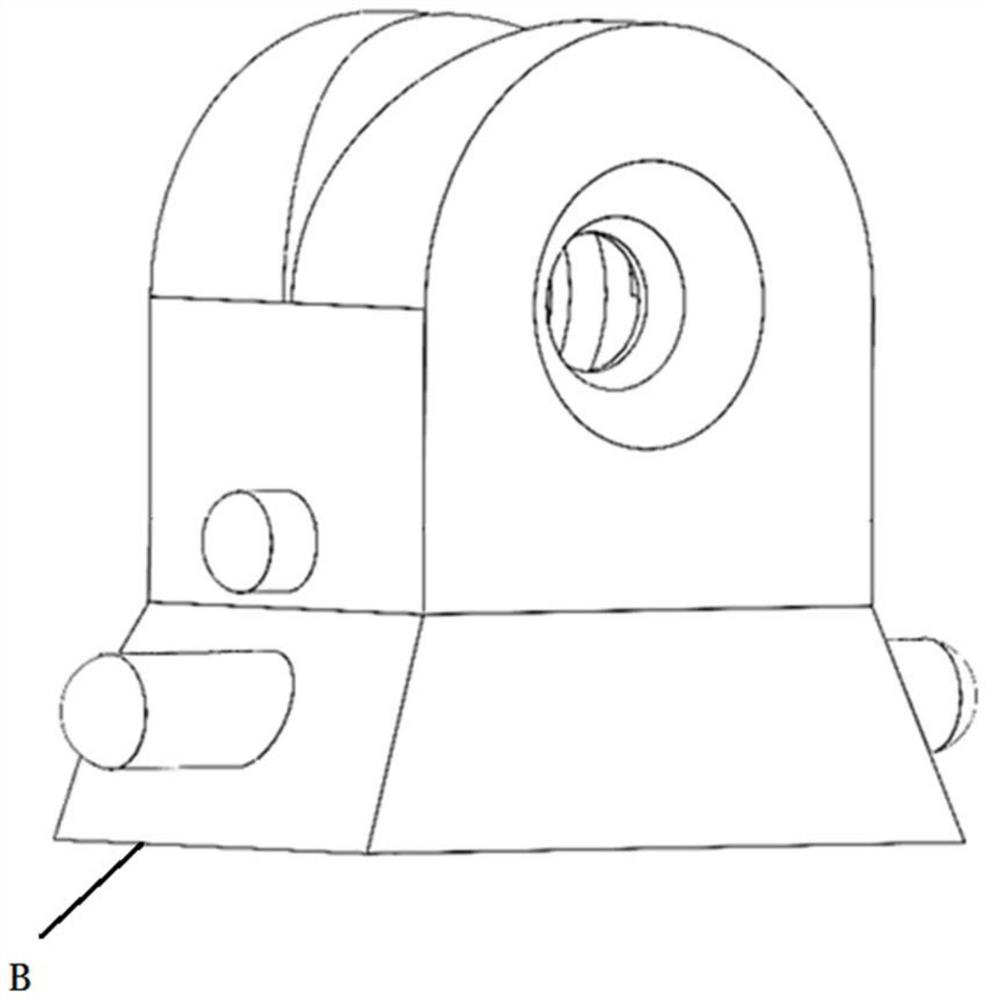

[0066] S101. Based on the actual shape and size, use geometric modeling software to construct a geometric model of the condenser throat coupled with the low-pressure exhaust cylinder; , the bypass diffusion device, and the communication port of the high-pressure hydrophobic expansion container have a great influence o...

Embodiment 2

[0136] According to engineering experience, the risk factor is taken as a safety margin. If the risk factor β>1-Δ, there is a risk of steam flow excitation in the cooling pipe; among them, Δ is a set normal number, and the range is (0, 1). This embodiment where Δ is set to 0.1.

[0137] The rest of the settings are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com