Method for detecting EHD injection instability caused by pulse liquid supply of injection pump

A technology of instability and detection method, applied in scattering characteristics measurement, liquid ejection device, ejection device, etc., can solve problems such as difficulty, poor contrast, and difficulty in extracting the edge of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

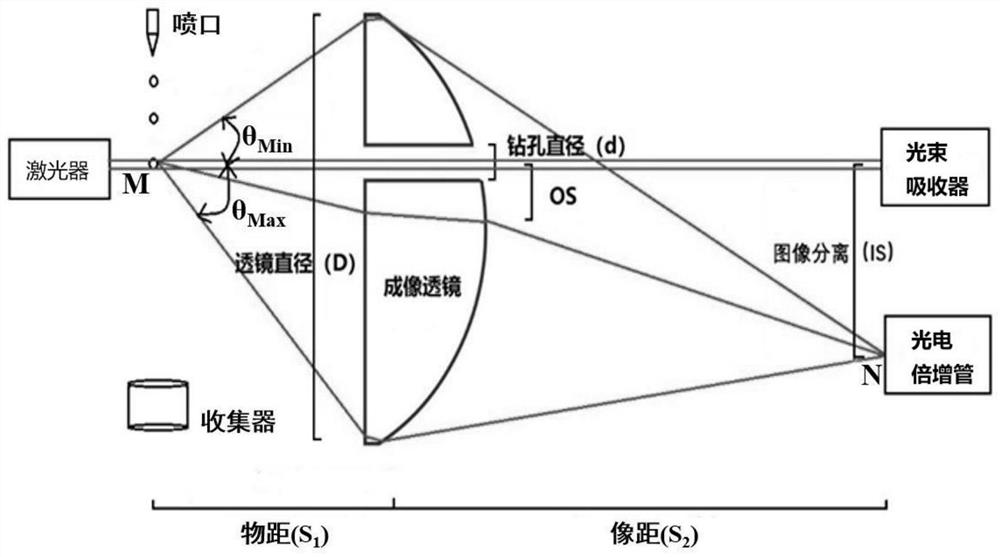

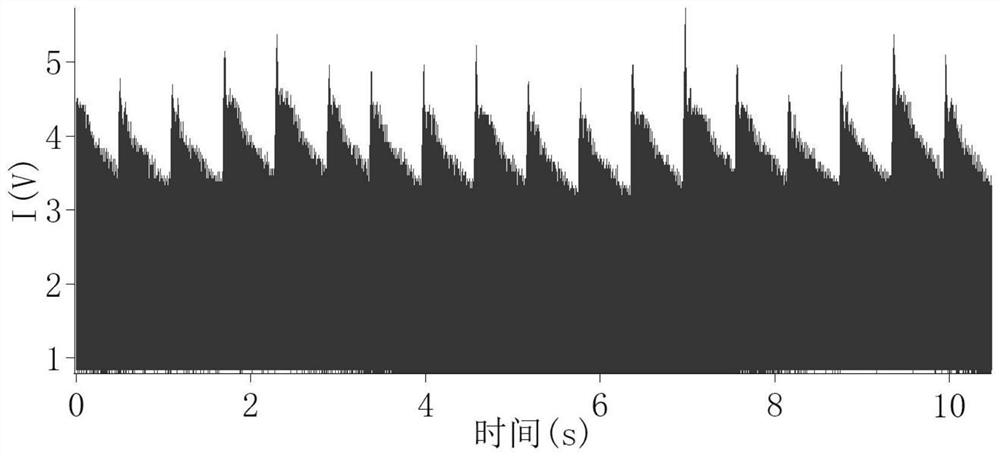

[0037] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

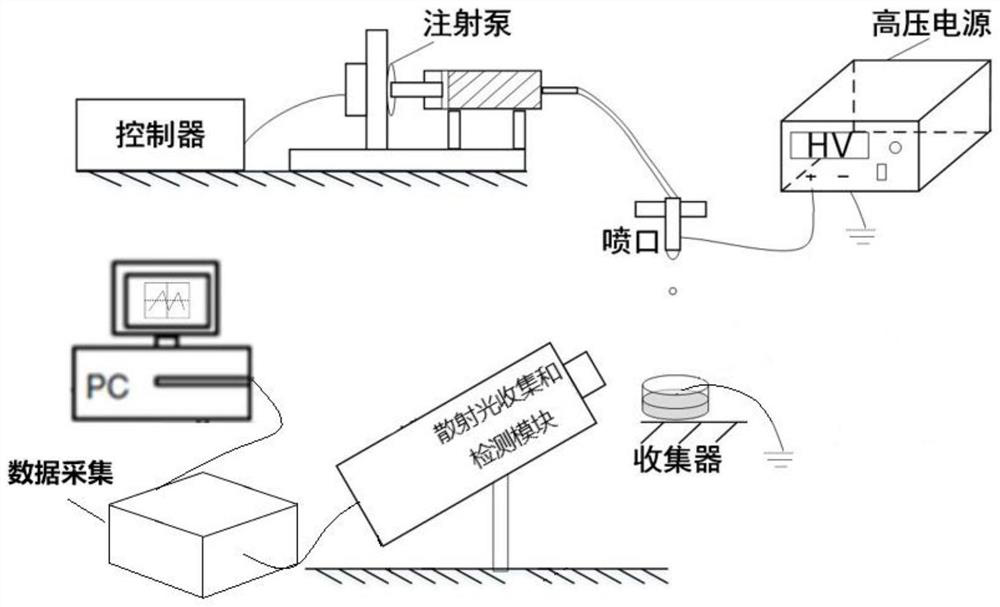

[0038] The whole experimental setup includes a droplet ejection system and a detection system for EHD ejection instability caused by pulsating liquid supply. The droplet ejection system mainly includes a liquid supply module based on a syringe pump, a high-voltage power supply and a droplet collector.

[0039] The liquid supply module includes two parts, namely a syringe pump and a controller, wherein the syringe pump is composed of a syringe, a lead screw translation stage driven by a stepping motor, and a stepping driver. The controller adopts a single-chip microcomputer, which can generate pulse waves. Whenever the controller sends out a pulse wave, the stepping motor will rotate a specific angle in a predetermined direction. Generally, the step angle of the stepper motor is 1.8°, and 16 times of subdivision can be achieved through the drive unit. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com