Heating furnace system and combustion and heat recovery method of heating furnace system

A heating furnace and waste heat recovery technology, which is applied in the fields of heating furnace system, combustion and heat recovery, can solve the problems of increasing the volume and investment of the heating furnace system, the heat cannot be recovered deeply, and the exhaust gas temperature cannot be too low, so as to achieve favorable Long-term stable operation, reduced floor area and equipment investment costs, reduced volume and investment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

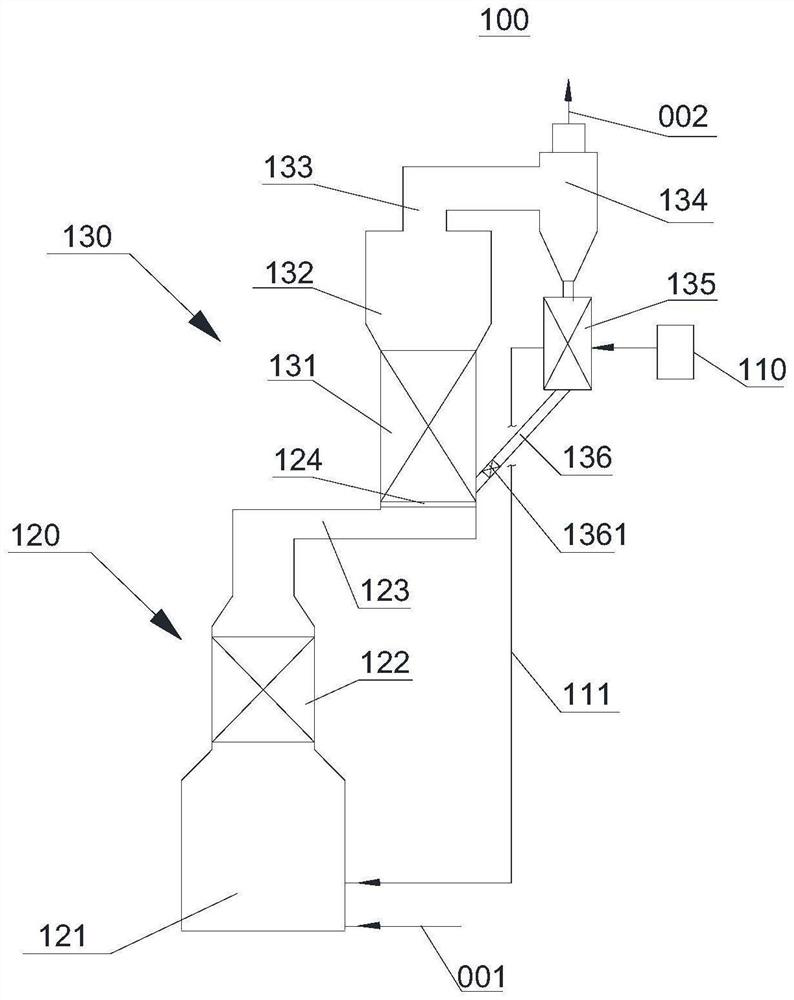

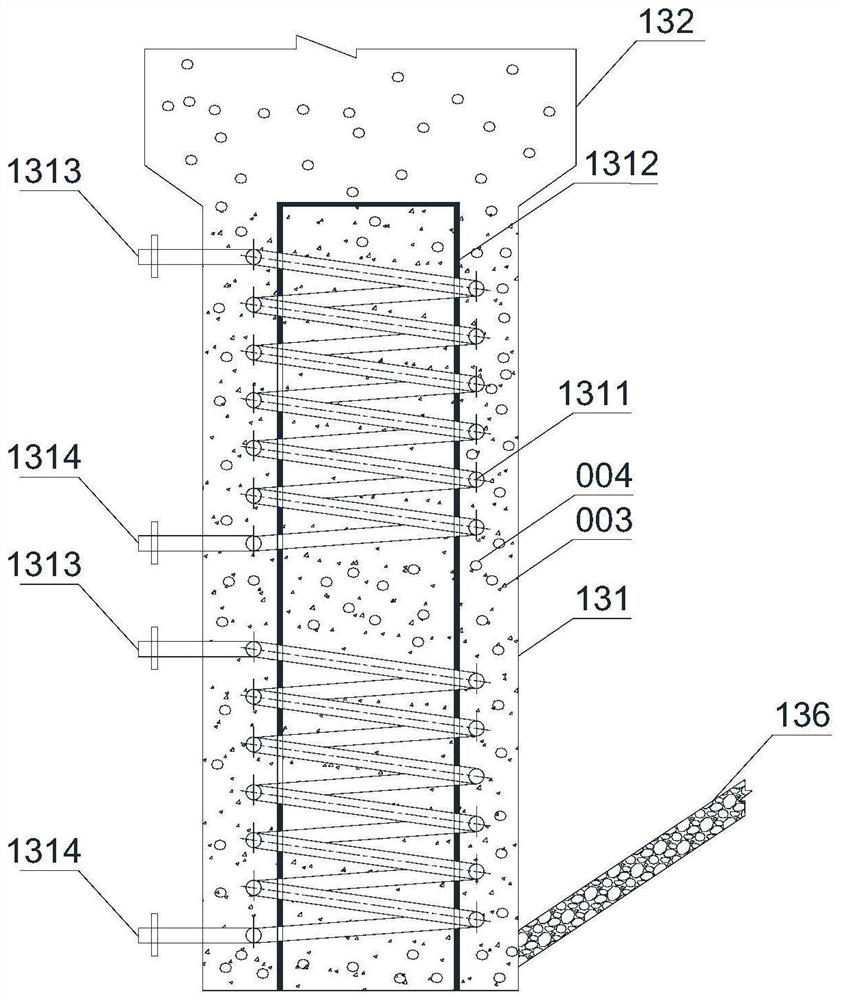

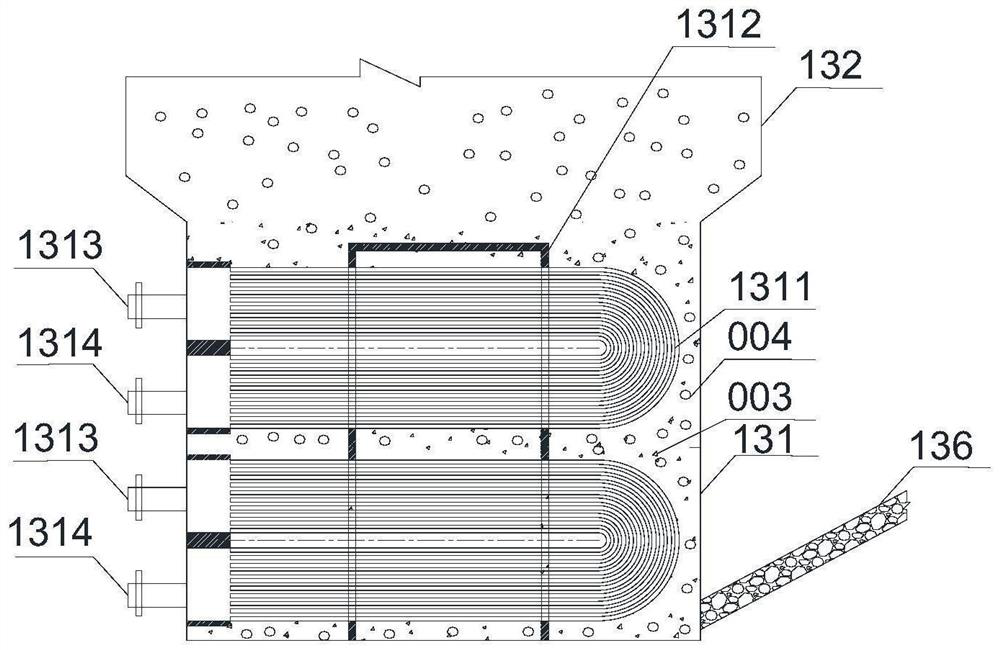

[0062] This embodiment provides a combustion and heat recovery method for a heating furnace system, which adopts figure 1 The device in the device conducts combustion and heat recovery, and the schematic structural diagram of the fluidized bed heat exchange section 131 is as follows figure 2 As shown, the schematic diagram of the structure of the moving bed gas-assisting preheating section 135 is as follows Figure 4 and Figure 5 As shown, the fuel is natural gas for a furnace with a heat load of 12 MW.

[0063] The specific operation steps are as follows:

[0064] The air compressor in the pressure inlet unit 110 will be 10800m 3 The normal temperature and normal pressure air per hour is inhaled, compressed and pressurized to about 180kPa, and after the temperature of the moving bed combustion-assistant preheating section 135 rises, it enters the combustion-assistant gas transmission line 111, and is transported from the fuel transmission line 001 1200m 3 After being mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com