Aluminum alloy surface treatment device and method

A surface treatment device and aluminum alloy technology, which is applied in the direction of cells, electrolytic processes, electrolytic components, etc., can solve problems affecting the use of the same product, reduce the number of stacking, improve the effect of coating, and ensure the effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] The specific embodiment is illustrated by the following examples:

no. 1 example

[0049] The first embodiment, this embodiment specifically discloses the carrying mechanism 200, please refer to Figure 4 As shown, the bearing mechanism 200 includes two supporting plates 210, and a plurality of bottom bearing members 220 are arranged between the two supporting plates 210, and the plurality of bottom bearing members 220 are arranged along the width direction of the supporting plates 210 to form a lower structure, which is used for large The workpiece is supported, and the top of the substructure is provided with a top carrier 240, see Figure 5 As shown, the top carrier 240 includes a carrier box 241, a box slot 2411 is opened in the carrier box 241, and a net pocket assembly 242 is arranged in the box slot 2411. Small workpieces provide bearing space, because small workpieces are small in size. If they are supported by the platform, they can only be supported by the surface, which will cause the small workpieces to be blocked by the support surface, which wi...

no. 2 example

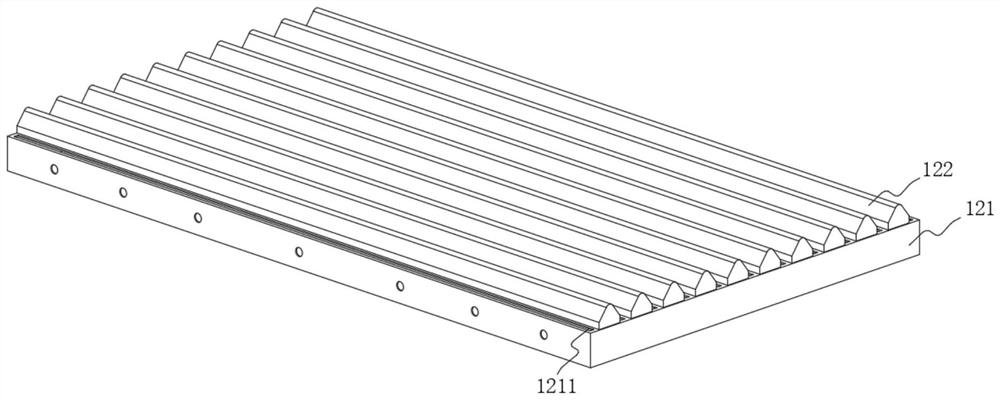

[0052] The second embodiment, this embodiment specifically discloses the anode member 120 , please refer to image 3 As shown, the anode member 120 includes an anode plate 121 and an anode support 122, a plurality of anode supports 122 are provided, the plurality of anode supports 122 are arranged on the top of the anode plate 121 along the width direction, and the cross section of the anode support 122 is "triangular" to increase the area where cations are generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com