Cementing and blocking type wall fixing agent for water-based drilling fluid as well as preparation method and application of cementing and blocking type wall fixing agent

A technology of water-based drilling fluid and wall-fixing agent, applied in chemical instruments and methods, drilling compositions, fibrous fillers, etc., can solve problems such as high drilling and completion costs, stuck drilling, and well wall collapse. , to achieve the effect of stabilizing the fractured formation well wall, enhancing the rock strength, and enhancing the temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

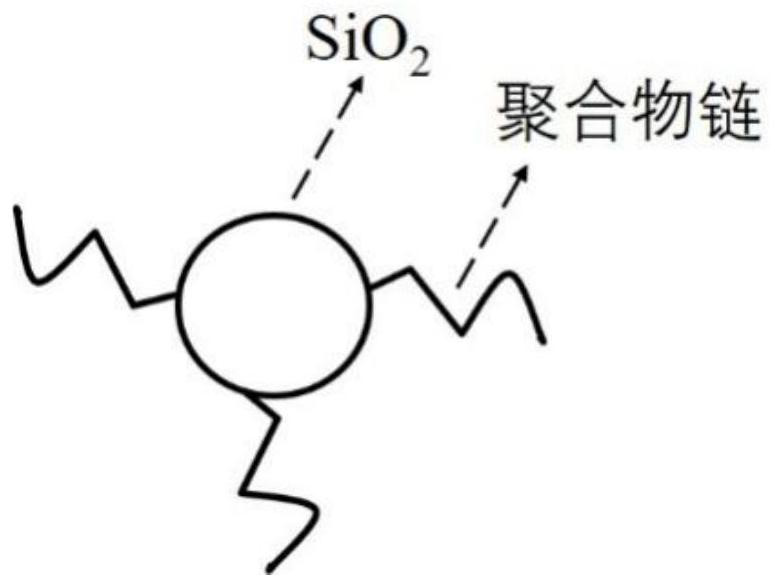

[0033] (1) Preparation of modified silica: disperse nano-silica in absolute ethanol to obtain dispersion system A, disperse γ-(methacryloyloxy)propyltrimethoxysilane (KH570) in water / absolute ethanol system, obtain dispersion system B, then mix the dispersion system A and the dispersion system B and adjust the pH value to 8-9, then add phenothiazine to react, after the reaction, filter and The obtained product is washed and dried to obtain modified silica;

[0034] (2) The modified silica, acrylamide, acrylic acid, sodium p-styrene sulfonate, dimethyl diallyl ammonium chloride, 1-ethyl-(3-dimethyl ammonium chloride) prepared in step (1) (base aminopropyl) carbodiimide, dopamine hydrochloride and water are mixed, and under stirring and heating conditions, a protective gas is introduced to remove oxygen, and then an initiator is added to react;

[0035] (3) After the reaction is completed, the product obtained in the step (2) is washed, dried and pulverized to obtain a cement...

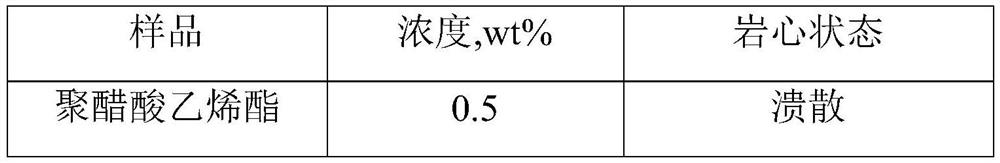

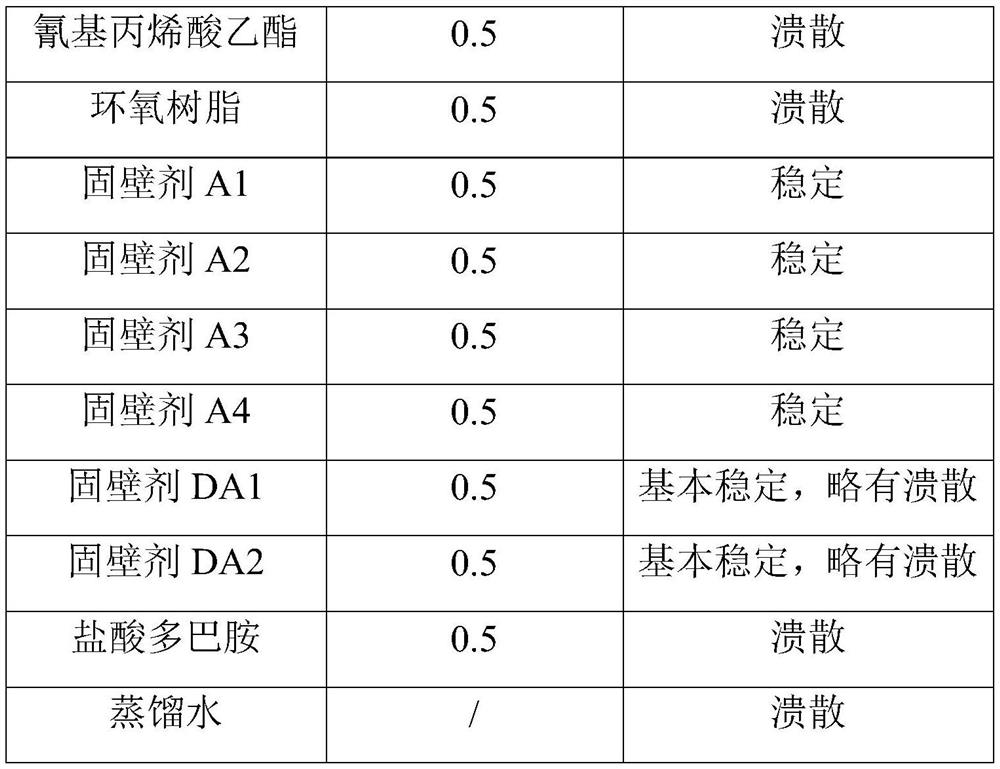

Embodiment 1

[0069] Take 2.5g modified silica, 15g acrylamide, 3.5g acrylic acid, 1.5g sodium p-styrene sulfonate, 2.5g dimethyl diallyl ammonium chloride, 0.2g 1-ethyl-(3-di Methylaminopropyl) carbodiimide and 5g of dopamine hydrochloride were added to the flask containing 150g of water, respectively, and stirred until fully dispersed; the flask was heated to 60°C in a water bath, kept stirring and heated, and deoxygenated with nitrogen for 30 minutes; Add 0.35g of V50 to the flask and maintain the reaction for 4h; after the reaction, the viscous product is taken out, washed with acetone for 3 times, dried and pulverized to obtain the wall solidifying agent A1.

Embodiment 2

[0071] Take 2.5g modified silica, 16g acrylamide, 3g acrylic acid, 1.8g sodium p-styrene sulfonate, 3g dimethyl diallyl ammonium chloride, 0.3g 1-ethyl-(3-dimethyl Aminopropyl) carbodiimide and 3.5 g of dopamine hydrochloride were added to the flask containing 160 g of water, and stirred until fully dispersed; the flask was heated to 65°C in a water bath, kept stirring and heated, and deoxygenated with nitrogen for 30 minutes; Add 0.3g of V50 to the medium, and maintain the reaction for 5h; after the reaction, take out the viscous product, wash it with acetone for 3 times, dry and pulverize it, it is the wall-fixing agent A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com