Hot continuous rolling impact prompt drop compensation coefficient calculation method and compensation method

A technology of compensation coefficient and calculation method, applied in calculation, metal rolling, metal rolling and other directions, can solve the problems of poor effect and low accuracy of rolling mill speed compensation value, achieve good compensation effect and avoid strip thickness exceeding the standard , The effect of ensuring the quality of hot-rolled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a calculation method for the impact velocity drop compensation coefficient of hot tandem rolling, and the calculation method includes:

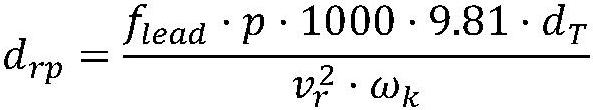

[0031] According to the leading speed coefficient, motor power, motor time constant, roll rotational angular velocity and motor rotational inertia, the impact speed drop compensation coefficient is calculated, and the impact speed drop compensation coefficient function is:

[0032]

[0033] where d rp is the downhill compensation coefficient; v r is the rotational angular velocity of the roll, rad / s; f lead is the leading speed coefficient; p is the motor power, kW; dx is the motor time constant, s; ω K is the moment of inertia of the motor, kg m 2 .

[0034] The calculation method of the hot continuous rolling impact speed drop compensation coefficient of the present embodiment has high accuracy in obtaining the speed drop compensation coefficient;

Embodiment 2

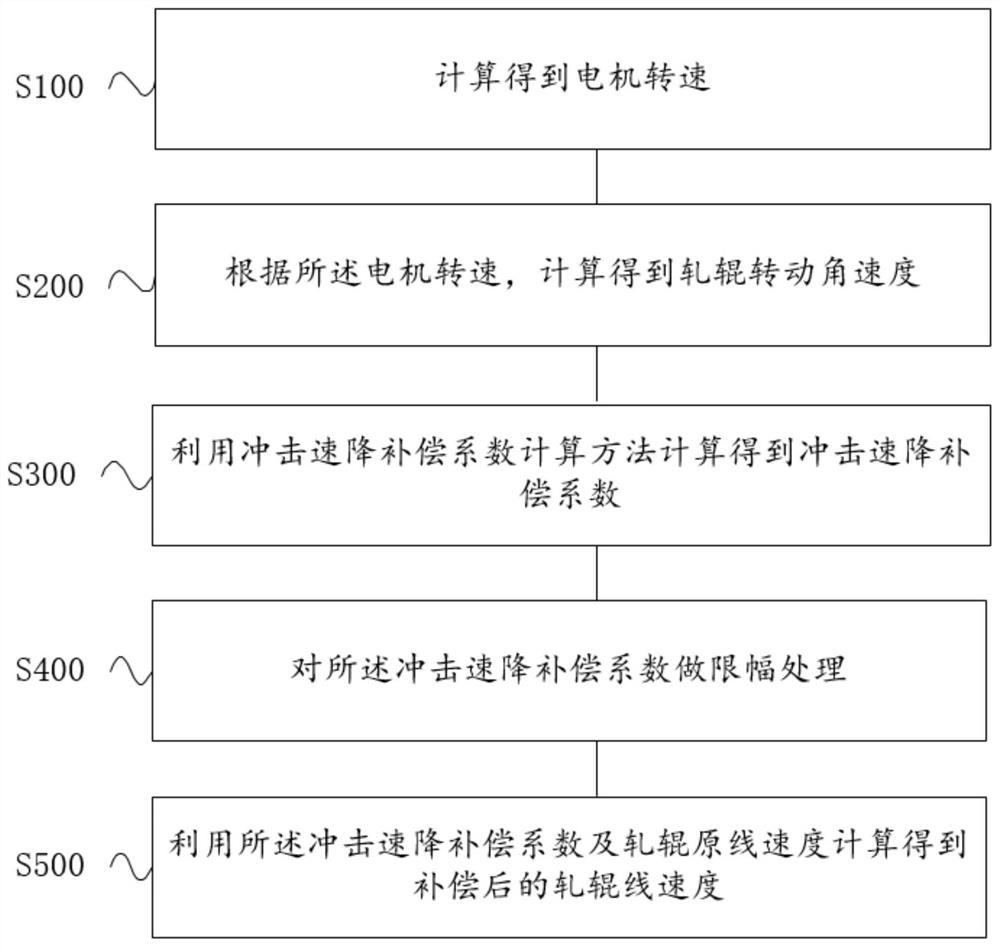

[0036] like figure 1 As shown, the present embodiment provides a method for compensating impact speed drop in hot tandem rolling, in which the method for calculating the impact speed drop compensation coefficient in hot tandem rolling as claimed in claim 1 is used, including:

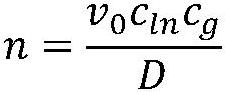

[0037] S100. Calculate the motor speed; in the process of calculating the motor speed, use the linear speed of the roll before the impact of the strip, the conversion coefficient of the linear speed to the speed, the gear box transmission ratio between the motor and the roll, and the diameter of the roll to calculate the motor speed, The motor speed function is:

[0038]

[0039] Among them, n is the motor speed, r / min; V 0 is the linear velocity of the roll before the impact of the strip, m / s; c ln is the conversion coefficient from linear velocity to rotational speed; c g is the gear box transmission ratio between the motor and the roll; D is the diameter of the roll, mm.

[0040] S200, accordi...

Embodiment 3

[0050] Aiming at the impact speed drop problem of the finishing mill in a hot tandem rolling line of a factory, the impact compensation coefficient d of the final stand F7 was calculated. rp . First, according to the field equipment and process setting data, the following parameters of the F7 stand of the finishing mill are determined: the linear speed of the roll before the impact V 0 =10.46m / s; gear box transmission ratio c g =1; conversion coefficient C from linear velocity to rotational speed ln= 19098.7917, roll diameter D = 665mm.

[0051] The linear speed of the roll before the impact, the conversion coefficient of the linear speed to the rotation speed, the transmission ratio of the gearbox and the diameter of the roll are brought into the motor speed function,

[0052]

[0053] Calculated motor speed n=300.4r / min;

[0054] Bring the motor speed into the roll rotation angular velocity function,

[0055]

[0056] calculate v r =31.5rad / s.

[0057] Then rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com