Vacuum dehumidifying and filtering system of extruder

A vacuum dehumidification and filtration system technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as low production efficiency, high energy consumption, and huge noise of the dehumidification system, and achieve continuous and stable working conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

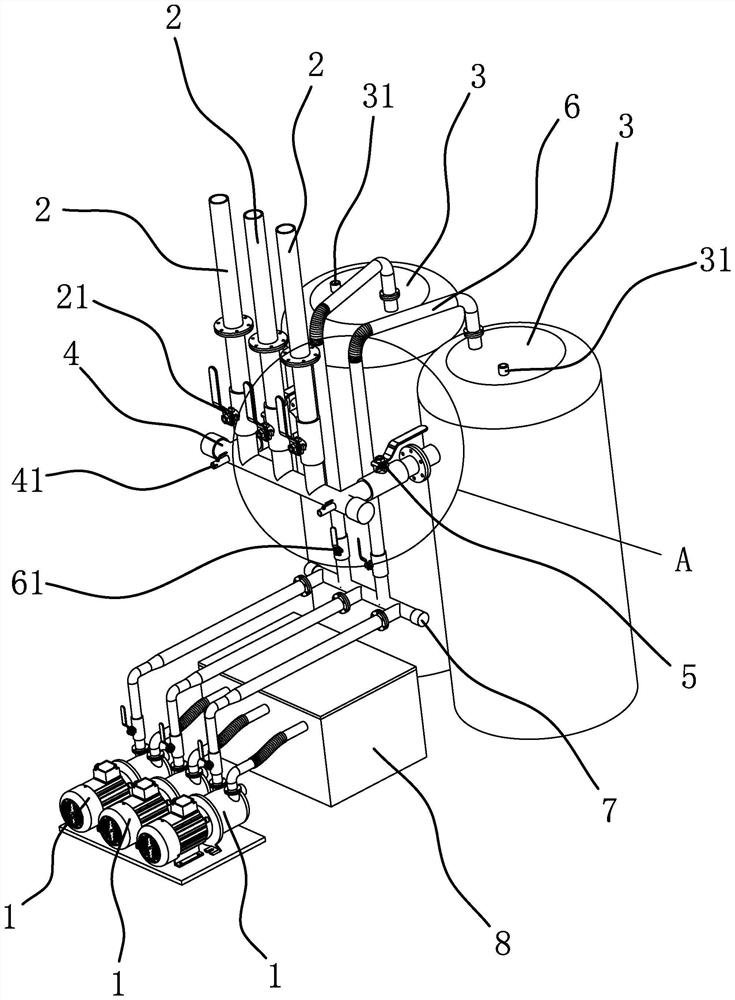

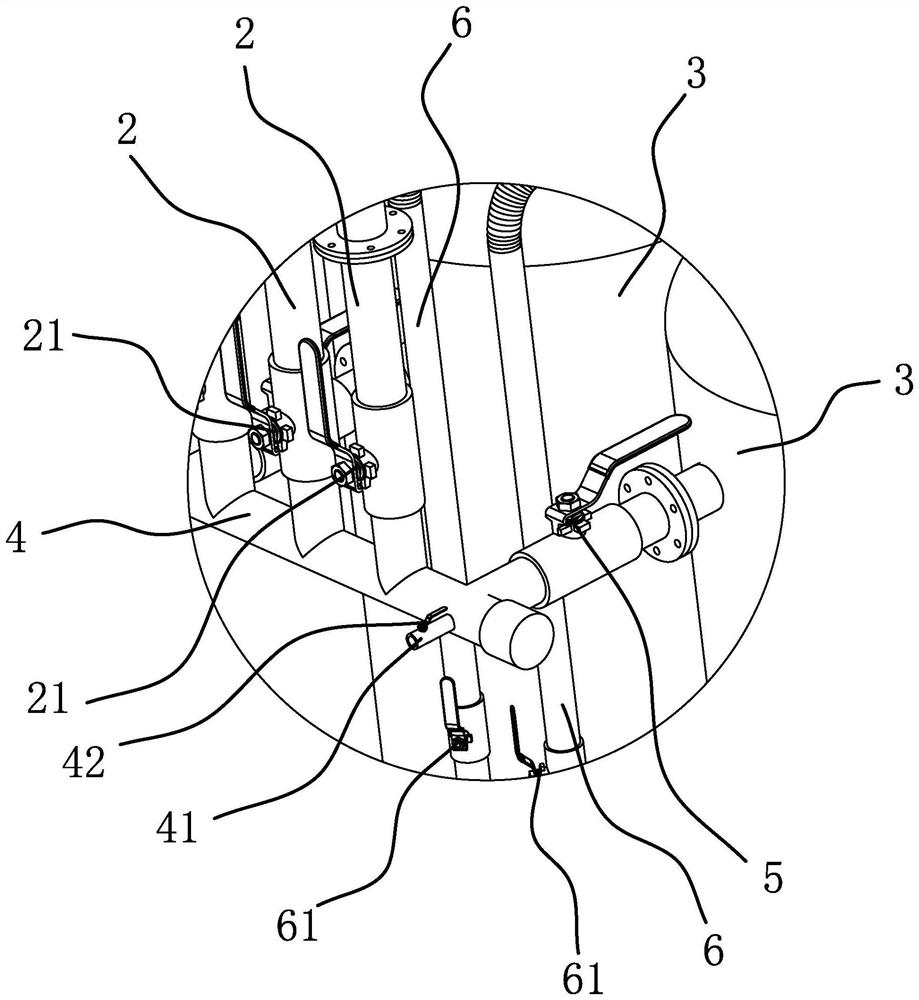

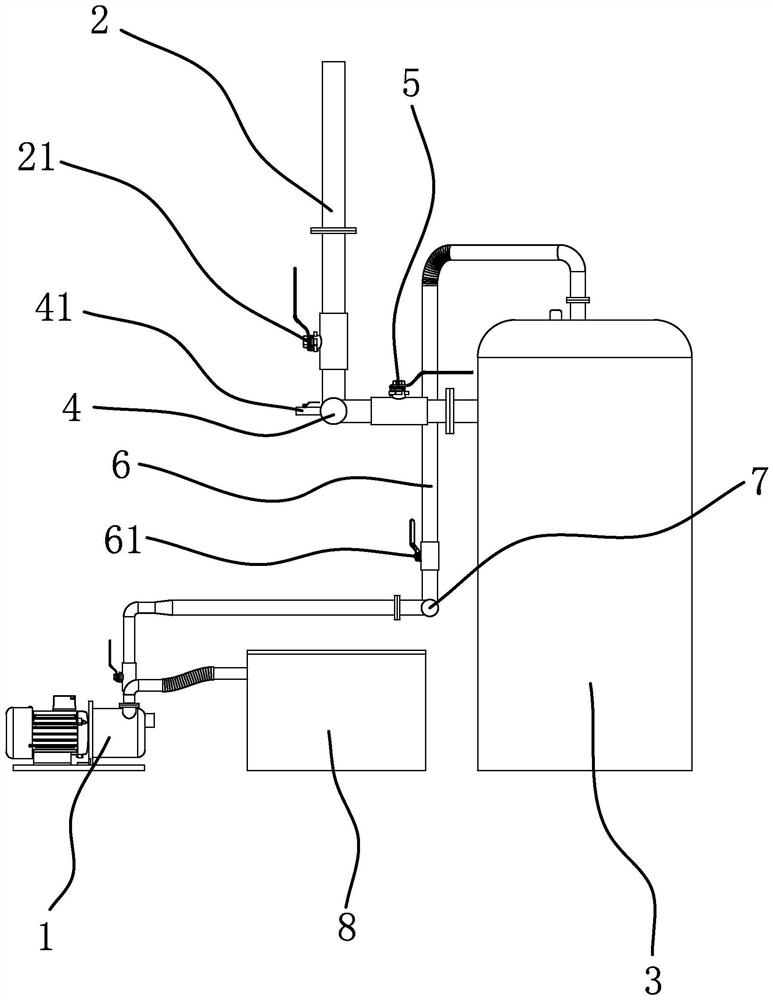

[0030] like Figure 1-3As shown, the vacuum dehumidification and filtration system of the extruder includes a vacuum pump 1, and the vacuum dehumidification and filtration system also includes a suction pipe 2 for communicating with a plurality of extruders at the same time and two filter storage materials for collecting powder materials. Tank 3, filter storage tank 3 and vacuum pump 1 are existing equipment, and the air extraction pipe 2 can be communicated with the inner cavities of the two filter storage tanks 3 through the middle section of the horizontal pipe one 4 at the same time, and each filter storage tank 3 is connected to the horizontal pipe. A control valve 5 for controlling the communication state of the horizontal pipe 1 4 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com