Material collecting device of flame cutting machine

A technology of flame cutting machine and material receiving device, which is applied to gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of stopping material collection, difficult to collect material, and large amount of blanking, so as to avoid stopping material collection. , Fast and convenient collection, and the effect of ensuring the quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

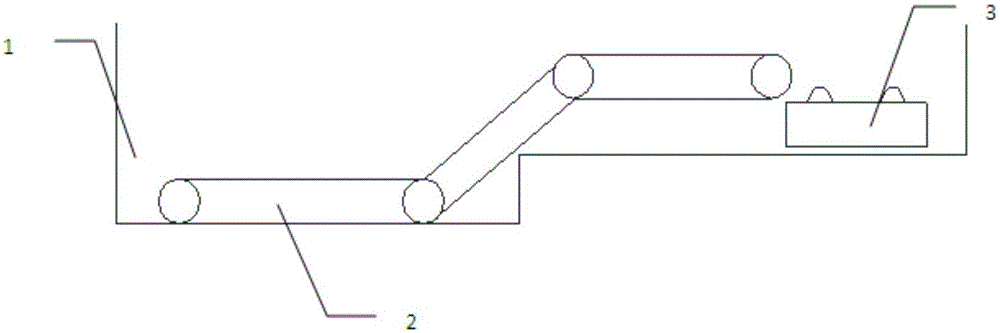

[0011] A material receiving device for a flame cutting machine, including a blanking tank 1, a transport device 2, a motor, and a material receiving box 3. The transport device 2 is composed of three belt conveyors, which are two horizontal belt conveyors and one inclined belt conveyor. The two-stage horizontal belt conveyor is located at the two ends of the inclined belt conveyor, and the lower section of the horizontal belt conveyor and part of the inclined belt conveyor in the transportation device 2 are located in the blanking tank. The motor and the transportation The device 2 is connected, and the receiving box 3 is located at one end of the transport device 2 . Cooling water is provided in the blanking tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com