Raw gas waste heat recycling device for ascending pipe of coke oven

A waste heat recovery and waste gas technology, which is applied in the heating of coke ovens, cleaning heat transfer devices, and carbonization gas discharge devices, can solve problems such as tar hanging, burst pipe leakage, and increased heat transfer resistance of rising pipes. Efficient recycling, high operating temperature, and the effect of reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

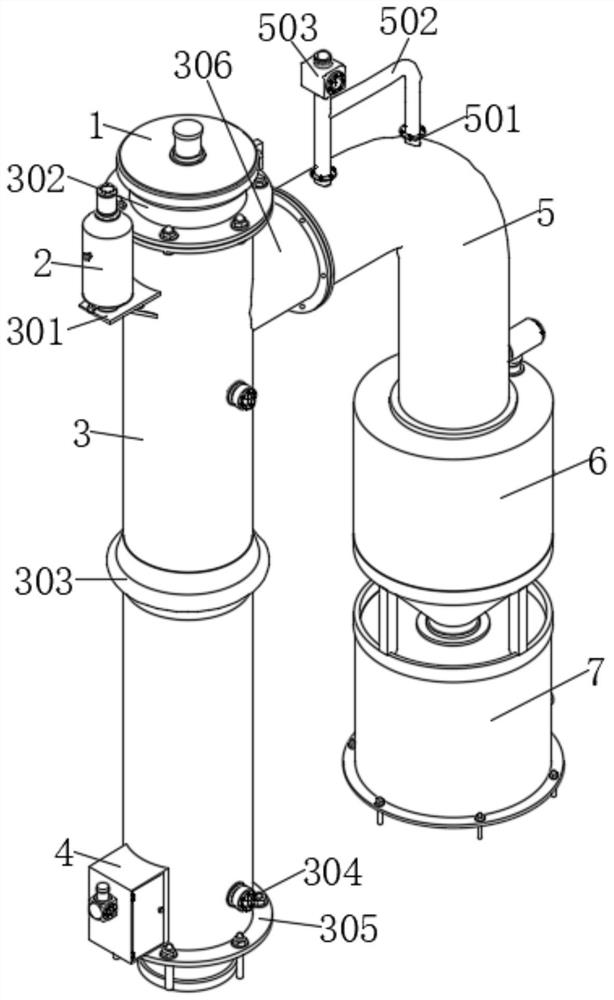

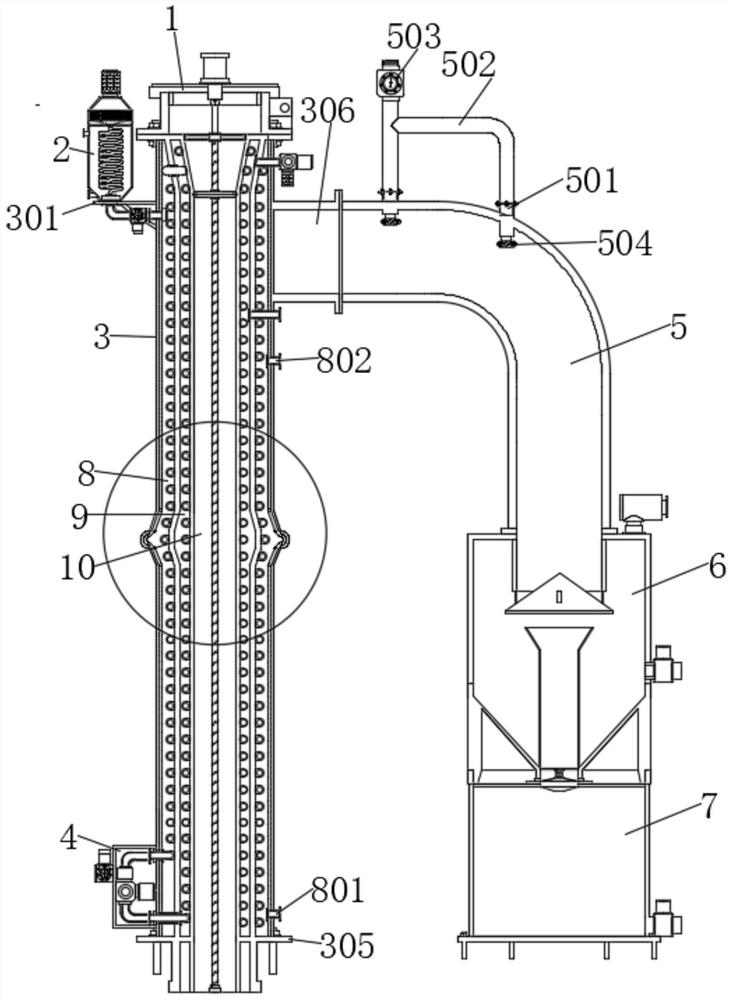

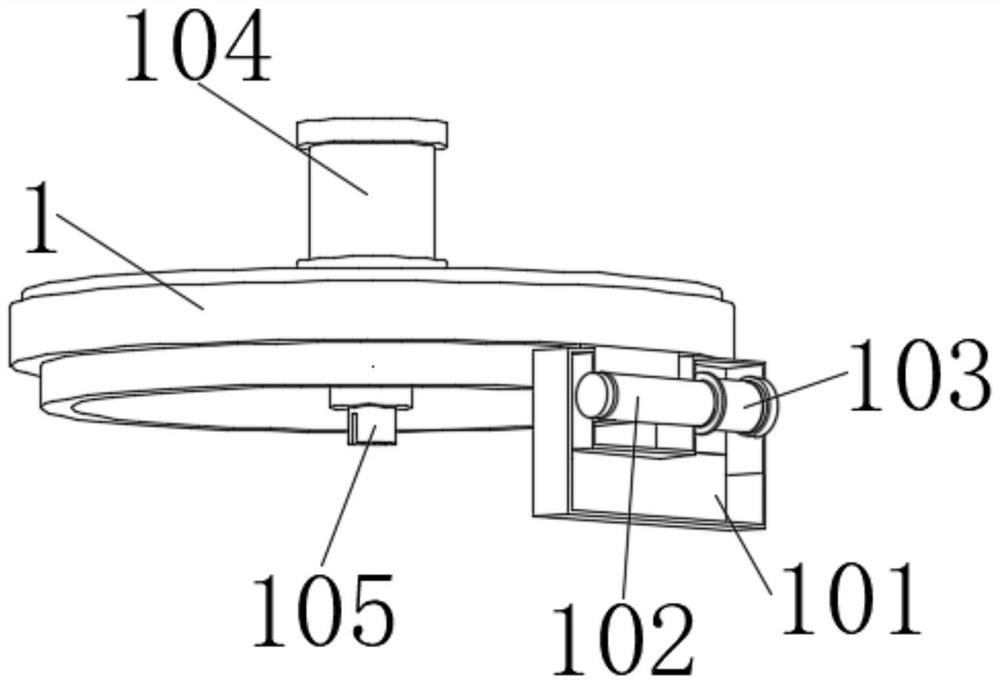

[0034] see Figure 1-8 , a waste heat recovery and utilization device for waste gas for coke oven risers proposed by the present invention includes a riser body 3, a box body 4 and an oil-vapor separation tank 6, and the riser body 3 passes through the outer pipe 8, the middle pipe 9. The inner pipe 10 is assembled, the mounting bracket 301 is installed on the outer side of the riser body 3, the top seat 302 is installed on the top of the riser body 3, and the expansion pipe 303 is installed in the middle of the expansion pipe 303, so A smoke outlet pipe 306 is installed on one side of the top of the riser body 3. The outer pipe 8 includes a protection pipe 803 and an insulating layer 804. An oil-conducting heat exchange pipe 805 is screwed inside the insulating layer 804. The inside of the outer tube 8 is provided with a middle tube 9, an oil guide and heat absorption tube 901 is screwed inside the middle tube 9, and the oil guide and heat exchange tube 805 is connected to th...

Embodiment 2

[0038] see Figure 2-8 , compared with the first embodiment, the present embodiment further includes: a water outlet end and a water inlet end are respectively installed on one side of the evaporator 2, The water inlet end is located below the water outlet end, and the water source is injected into the casing 201 through the water inlet end, and the water outlet end is connected with a pipeline to facilitate the collection of hot water energy. The meter 304 can monitor the temperature of the oil inlet pipe 405 and the temperature of the oil outlet pipe 404 of the heat transfer oil in real time, and the bottom of the riser body 3 is welded with a chassis 305, which can facilitate the installation of the riser body 3, and the input end of the circulating oil pump 401 is installed with a connecting pipe 403, an oil inlet pipe 405 is installed at one end of the connecting pipe 403, and the oil inlet pipe 405 is connected to the oil guide and heat absorption pipe 901 throughly. 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com