Diatom gypsum composite material plate and production and installation method thereof

A composite material board and gypsum material technology, which is applied in the field of diatom gypsum composite material board and its production and installation, can solve the problems of fire prevention, poor waterproof performance, easy to expand due to moisture, short service life, etc., and achieve short installation period and convenient construction , produce easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

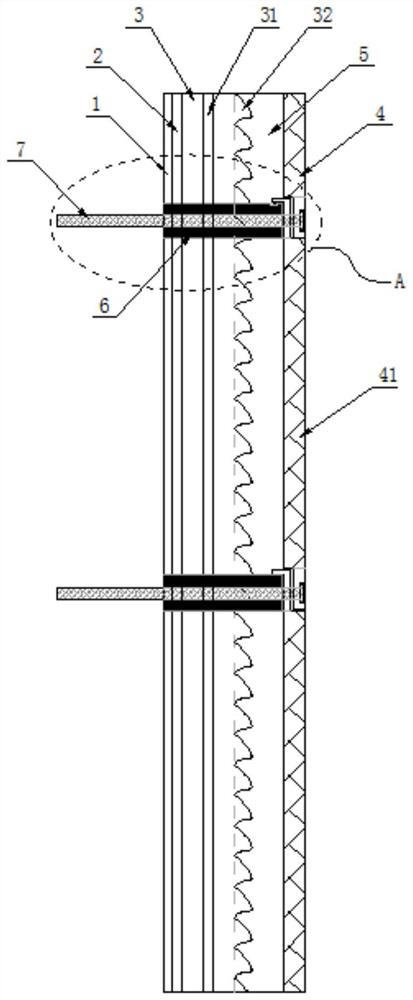

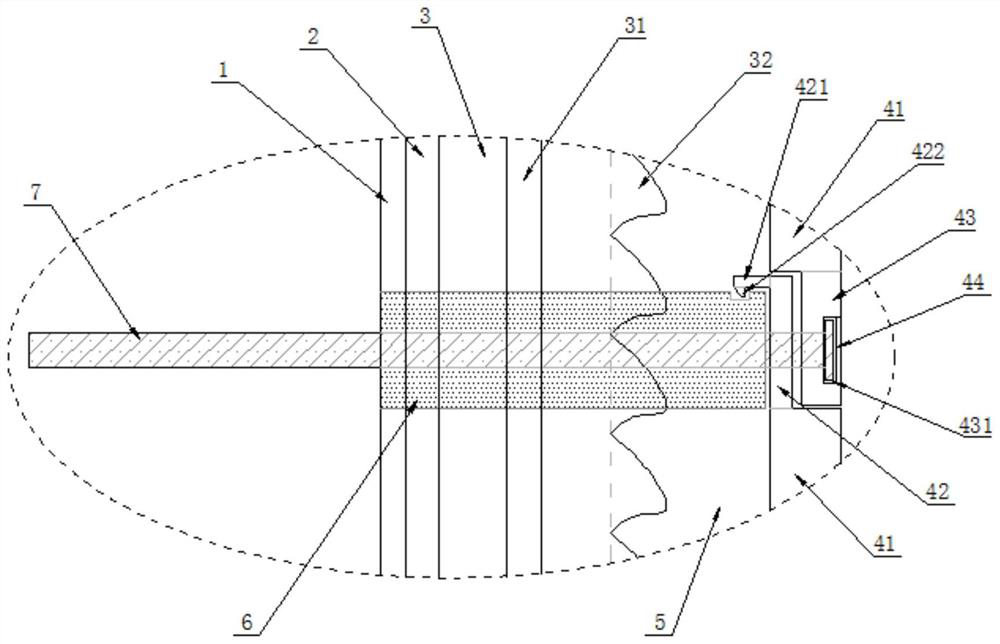

[0029] like figure 1 , 2 As shown, a diatom gypsum composite material board includes a waterproof layer 1 , a thermal insulation layer 2 , a diatom gypsum layer 3 , and a panel layer 4 sequentially from inside to outside.

[0030] The diatom gypsum layer 3 is provided with a grid-shaped skeleton device 31, and the grid-shaped skeleton device 31 is a metal wire mesh, a plastic wire mesh, or a glass fiber mesh cloth. The outer side of the diatom gypsum layer 3 is provided with a wave-like or ravine-like structure 32 .

[0031] The waterproof layer 1, the thermal insulation layer 2, and the diatom gypsum layer 3 are vertically provided with a support member 6. The support member 6 runs through the waterproof layer 1, the thermal insulation layer 2 and the diatom gypsum layer 3, and the front end of the support member 6 is connected to the inner side of the waterproof layer 1. Flush, the rear end of the support 6 penetrates and is exposed on the outer side of the diatom gypsum l...

Embodiment 2

[0035] like figure 1 , 2As shown, a diatom gypsum composite material board, its structure is basically the same as the embodiment 1, the difference is: the diatom gypsum material, in parts by weight, includes the following components: 400 parts of desulfurized gypsum, 150 parts of diatomite , 6 parts of nano titanium dioxide, 10 parts of wood fiber, 50 parts of 40-70 mesh fine sand, 60 parts of 70-140 mesh fine sand, 20 parts of heavy calcium, 5 parts of lime calcium, 3 parts of sodium alginate, 5 parts of silane coupling agent portion, appropriate amount of water. The particle size of diatomite includes 60μm, in terms of weight ratio, 30% with particle size 60μm . The particle size of the nano titanium dioxide is 20-40 nm.

Embodiment 3

[0037] like figure 1 , 2 As shown, a diatom gypsum composite material board, its structure is basically the same as Example 1, the difference is: the diatom gypsum material, in parts by weight, includes the following components: 350 parts of desulfurized gypsum, 180 parts of diatomite , 2 parts of nano titanium dioxide, 7 parts of wood fiber, 20 parts of 40-70 mesh fine sand, 80 parts of 70-140 mesh fine sand, 50 parts of heavy calcium, 20 parts of lime calcium, 5 parts of sodium alginate, 3 parts of silane coupling agent portion, appropriate amount of water. The particle size of diatomite includes 60μm, in terms of weight ratio, the particle size 60μm accounts for 30% . The particle size of the nano titanium dioxide is 20-40 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com