Liquid mist defoaming device for falling film absorption tower

A technology of falling film absorption tower and absorption tower, which is applied in the field of liquid mist demisting device, can solve the problems of air, flowers, trees, air pollution, acid gas and alkaline gas, etc., so as to improve efficiency, gas The effect of smooth channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

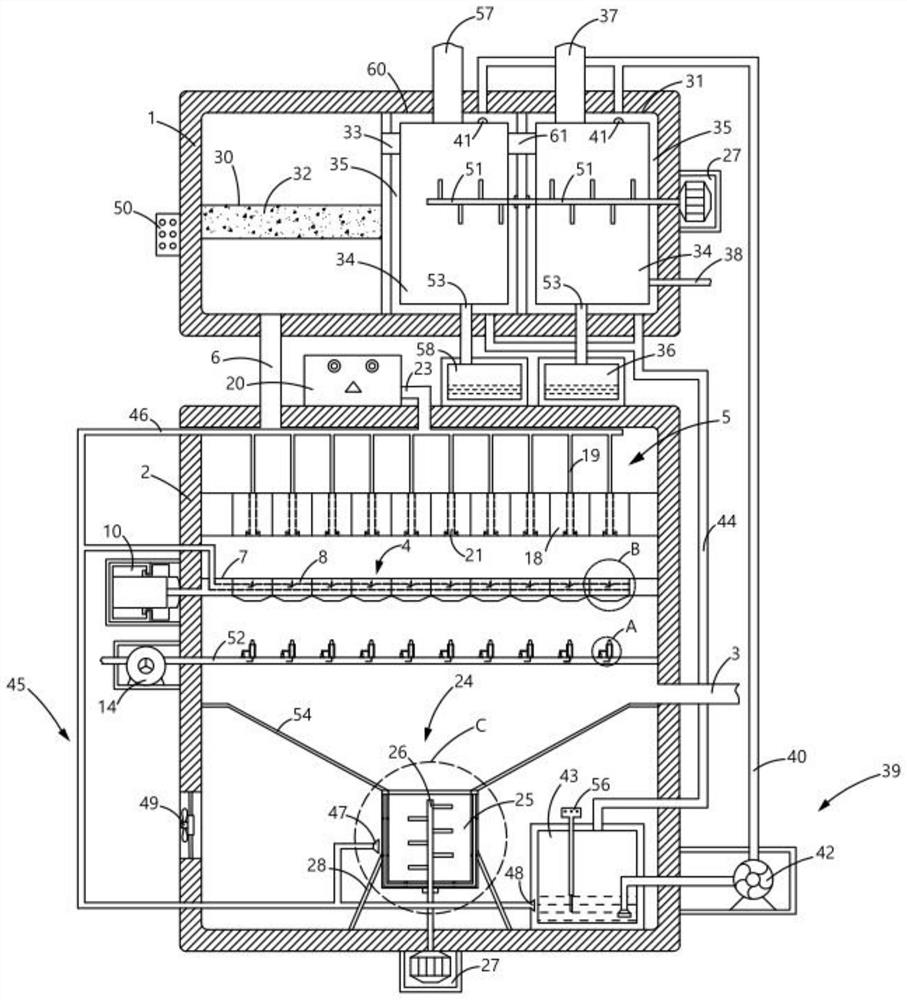

[0024] see Figure 1 to Figure 6 , the present invention provides a kind of technical scheme:

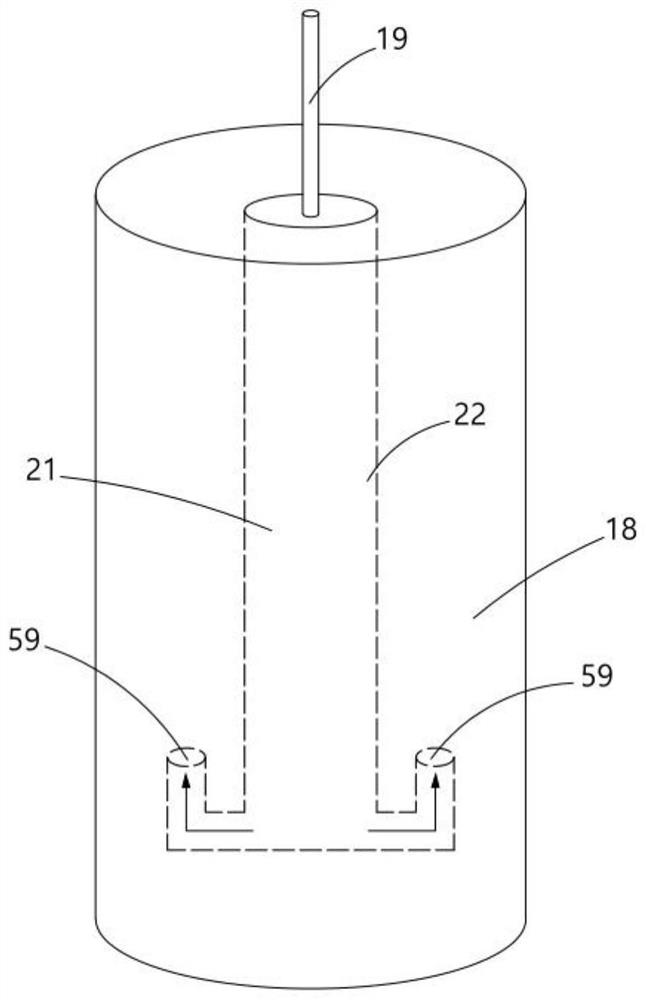

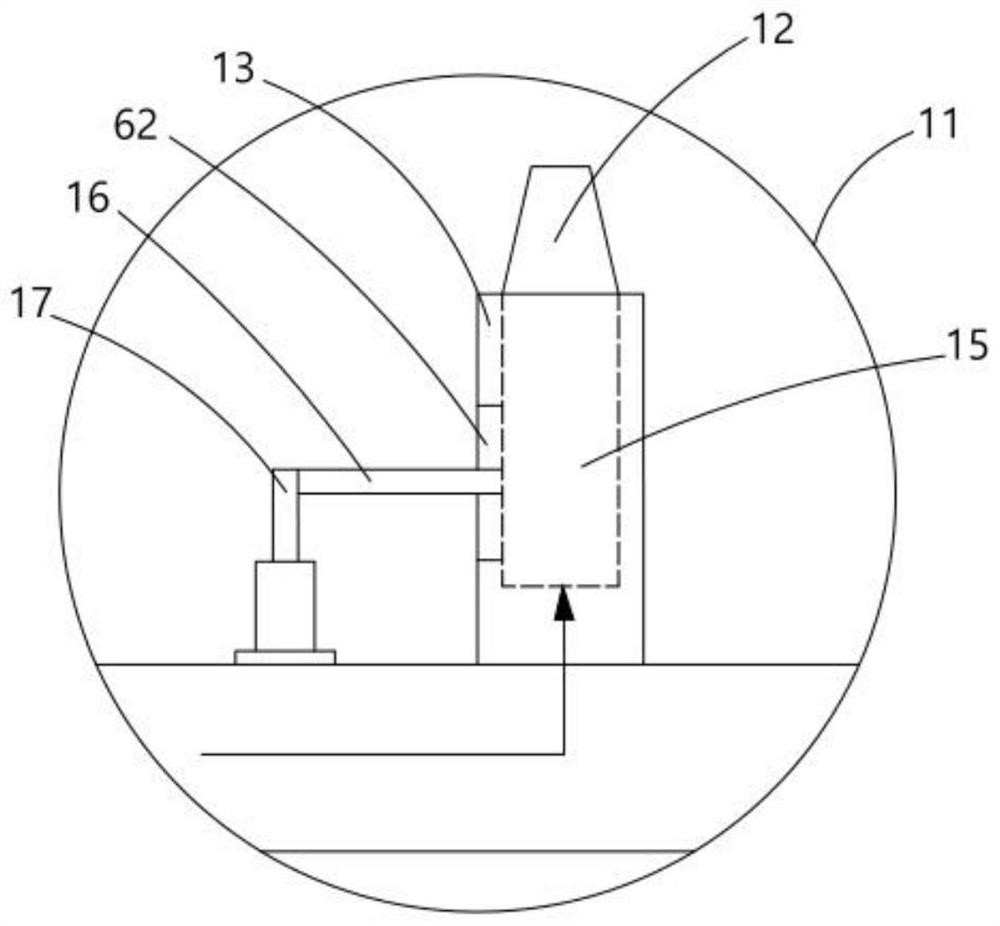

[0025] A liquid mist defoaming device for a falling film absorption tower, comprising an upper absorption tower 1 and a lower absorption tower 2, wherein the lower absorption tower 2 includes a first air inlet pipe 3, a liquid removal device 4, a liquefaction device 5 and The first air outlet pipe 6, the right side of the lower absorption tower 2 is connected with the first air inlet pipe 3, and the inner wall of the lower absorption tower 2 is welded with a liquid removing device 4, which is used to filter and remove the droplets in the liquid mist. A liquefaction device 5 is welded directly above the liquid removal device 4, which is used to liquefy and settle the gas in the waste gas into the liquid removal device 4. A first gas outlet pipe 6 is connected above the lower absorption tower 2 and extends to the upper absorption tower 1, so The liquid removing device 4 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com