Preparation and application of self-supporting nitrogen-doped carbon nanotube loaded platinum nano-cluster

A nitrogen-doped carbon, carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems affecting the performance and future development of DMFCs, catalyst active surface area reduction, charge transfer resistance increase and other problems to achieve good electrocatalytic activity and long-term stability, improve insufficient electrical conductivity, and prevent dissolution and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

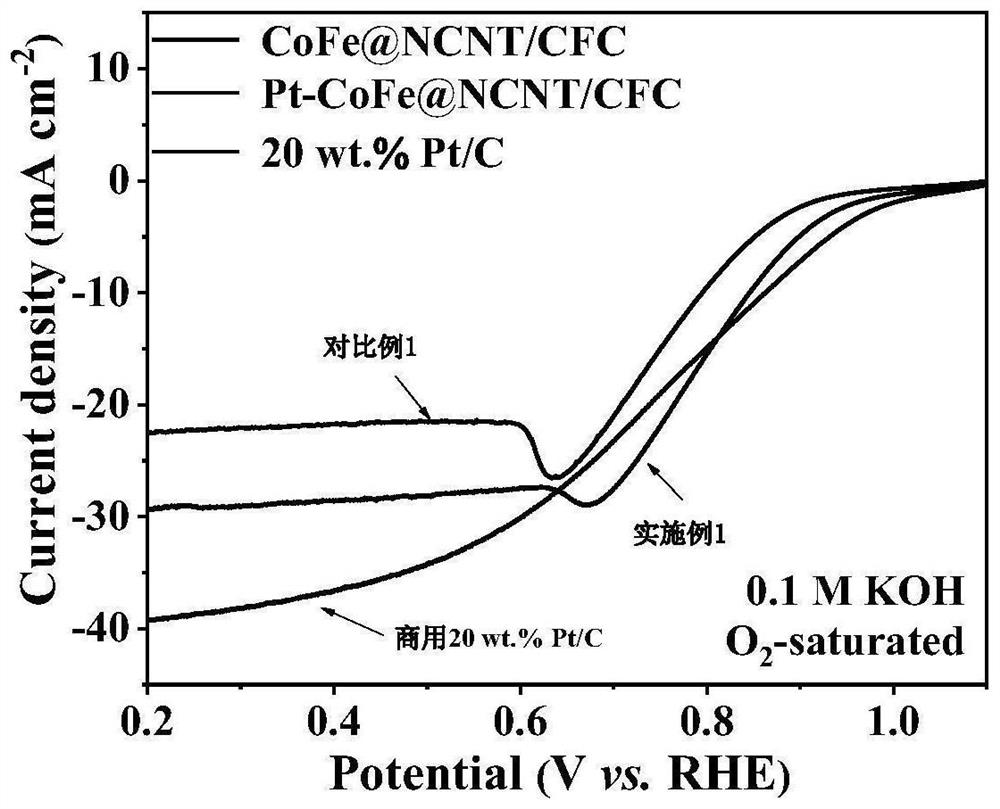

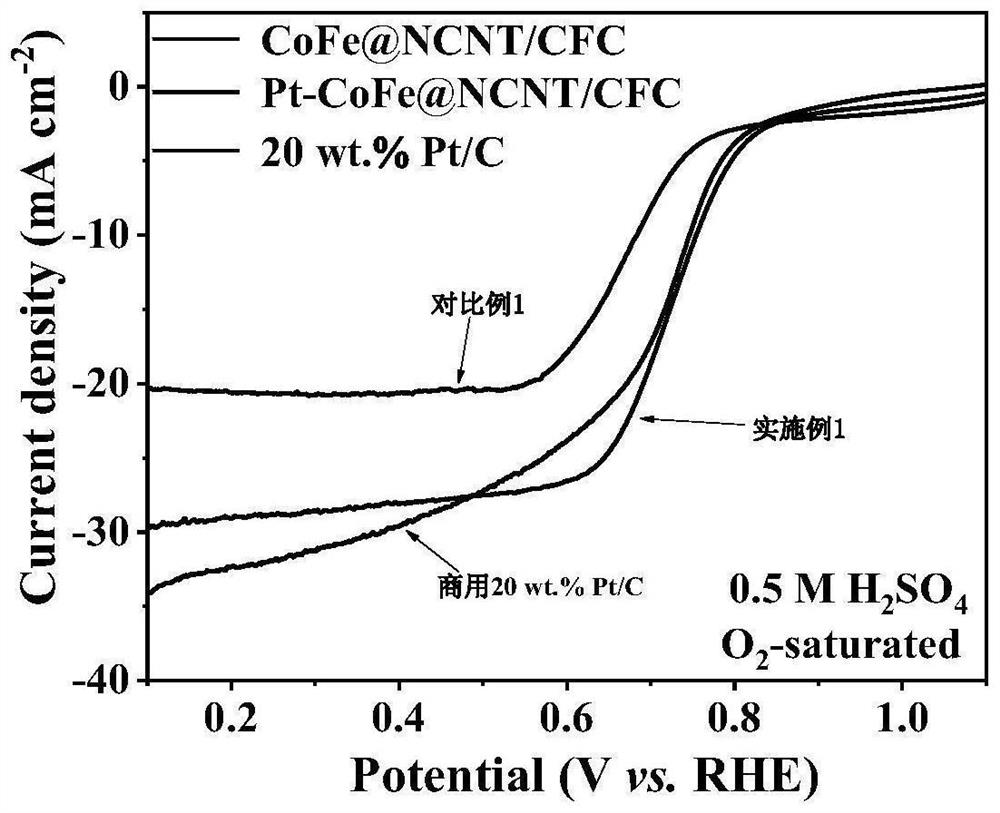

Embodiment 1

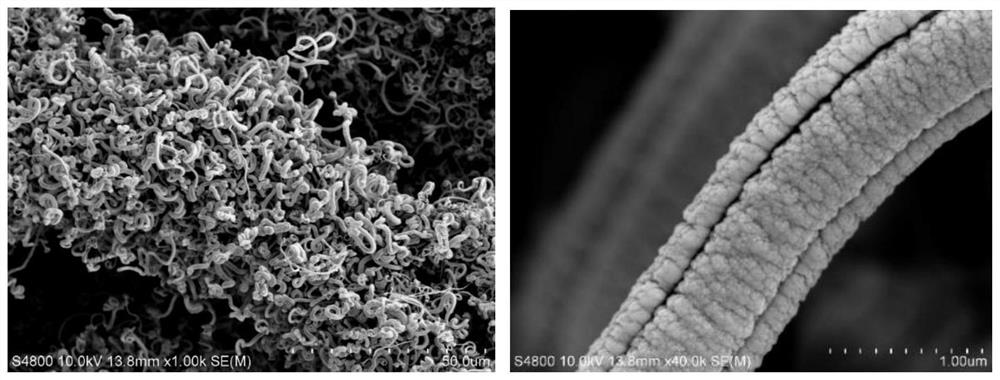

[0031] Example 1: Preparation of a self-supporting nitrogen-doped carbon nanotube-supported platinum nanocluster, which specifically includes the following steps:

[0032] (1) Synthesis of cobalt iron nanowires:

[0033] Take a carbon cloth with a size of 3 cm × 4 cm and sonicate it in a 10 wt.% potassium permanganate solution for 10 min, continue to sonicate in deionized water and ethanol until the solution is completely clear, and then place it in a vacuum oven at 60 °C for 12 h. 388 mg of cobalt nitrate hexahydrate, 270 mg of ferric nitrate nonahydrate, 186 mg of ammonium fluoride and 600 mg of urea were added to 40 ml of deionized water while stirring, and continued stirring at room temperature for 10 min to form a uniform mixed solution. Transfer to a hydrothermal reactor, immerse the carbon cloth in it, and let it stand at 120 °C for 6 h. Then, the carbon cloth was taken out, washed with deionized water and ethanol in turn, and finally dried in a vacuum oven at 40 °C fo...

Embodiment 2

[0051] Example 2: Preparation of a self-supporting nitrogen-doped carbon nanotube-supported platinum nanocluster, which specifically includes the following steps:

[0052] (1) Synthesis of cobalt iron nanowires:

[0053] Take a carbon cloth with a size of 3 cm × 4 cm and sonicate it in a 10 wt.% potassium permanganate solution for 10 min, continue to sonicate in deionized water and ethanol until the solution is completely clear, and then place it in a vacuum oven at 60 °C for 12 h. 388 mg of cobalt nitrate hexahydrate, 270 mg of ferric nitrate nonahydrate, 186 mg of ammonium fluoride and 600 mg of urea were added to 40 ml of deionized water while stirring, and continued stirring at room temperature for 10 min to form a uniform mixed solution. Transfer to a hydrothermal reactor, immerse the carbon cloth in it, and let it stand at 120 °C for 6 h. Then, the carbon cloth was taken out, washed with deionized water and ethanol in turn, and finally dried in a vacuum oven at 40 °C fo...

Embodiment 3

[0059] Example 3: Preparation of a self-supporting nitrogen-doped carbon nanotube-supported platinum nanocluster, which specifically includes the following steps:

[0060] (1) Synthesis of cobalt iron nanowires:

[0061] Take a carbon cloth with a size of 3 cm × 4 cm and sonicate it in a 10 wt.% potassium permanganate solution for 10 min, continue to sonicate in deionized water and ethanol until the solution is completely clear, and then place it in a vacuum oven at 60 °C for 12 h. 388 mg of cobalt nitrate hexahydrate, 270 mg of ferric nitrate nonahydrate, 186 mg of ammonium fluoride and 600 mg of urea were added to 40 ml of deionized water while stirring, and continued stirring at room temperature for 10 min to form a uniform mixed solution. Transfer to a hydrothermal reactor, immerse the carbon cloth in it, and let it stand at 120 °C for 6 h. Then, the carbon cloth was taken out, washed with deionized water and ethanol in turn, and finally dried in a vacuum oven at 40 °C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com