Furfural residue combustion boiler with built-in vibration mechanism and high combustion efficiency

A technology of combustion efficiency and furfural slag, which is applied in the field of furfural slag combustion boilers, can solve the problems affecting the treatment of furfural slag, insufficient combustion of furfural slag, agglomeration of furfural slag, etc., and achieve the effect of convenient combustion, improved effect and improved combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

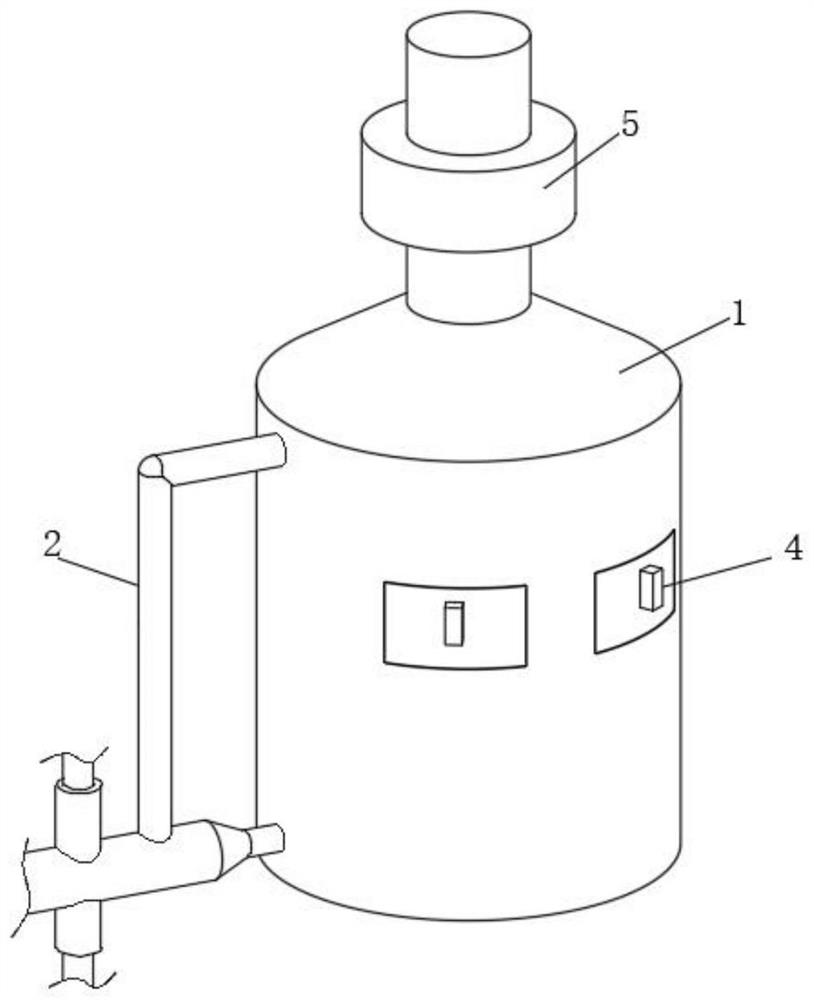

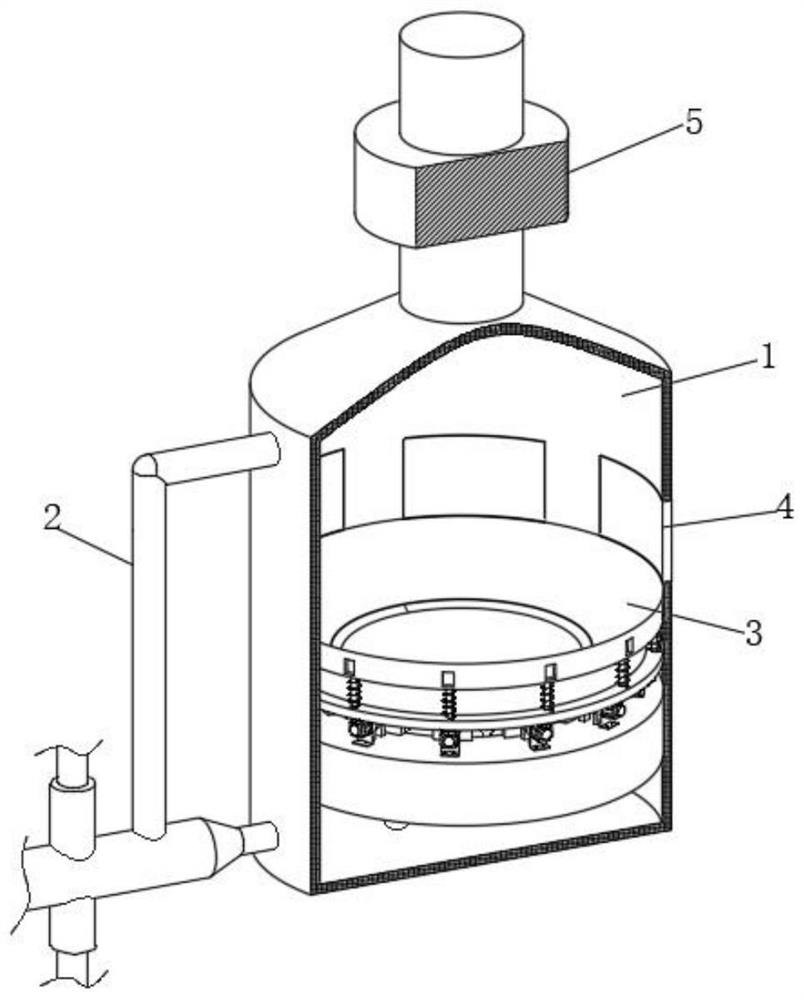

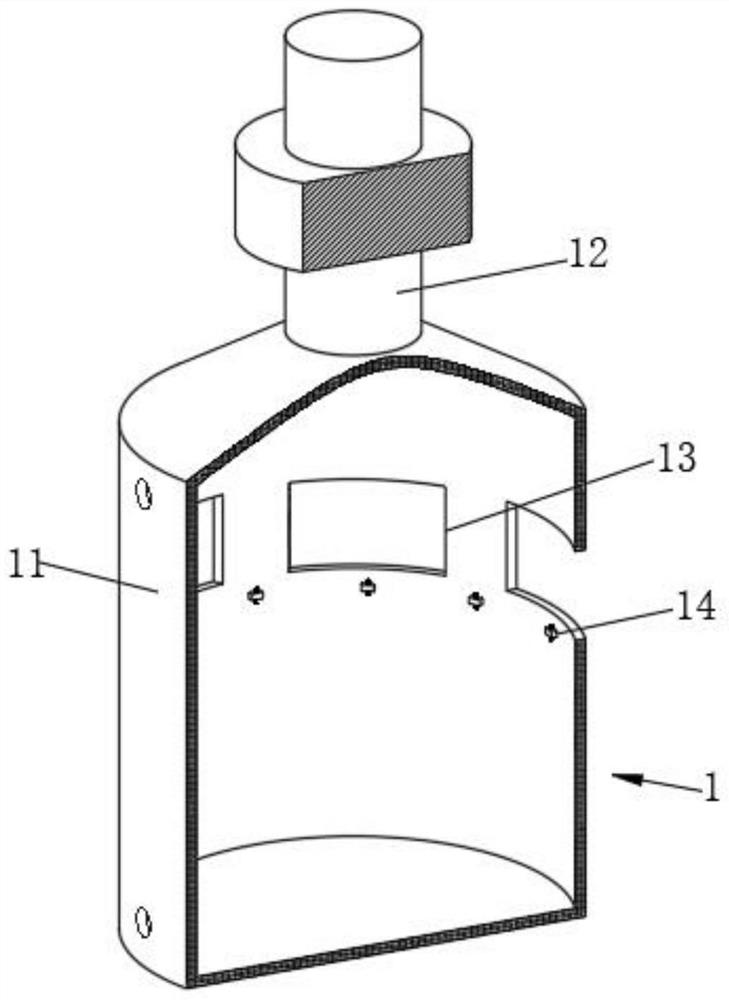

[0038] see Figure 1-Figure 9 As shown, the purpose of this embodiment is to provide a furfural slag combustion boiler with a built-in shock material mechanism with high combustion efficiency, including a combustion furnace 1 and an exhaust device 2 arranged on one side of the combustion furnace 1, and the interior of the combustion furnace 1 A processing device 3 is provided. The combustion furnace 1 includes a combustion barrel 11 and a smoke exhaust pipe 12 installed on the top of the combustion barrel 11. The smoke exhaust pipe 12 is equipped with a dust removal device 5 for dedusting the gas, and the combustion barrel 11 is close to the upper end of the side wall. There are several discharge ports 13 on the top, and a shielding plate 4 is installed in the discharge port 13. The exhaust device 2 includes an air pipe 21 and an oxygenation pipe 22 and a gas pipe 23 installed on the air pipe 21. The air pipe 21 A closing pipe 24 is installed at one end, and an exhaust pipe 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com