Surface treatment method for nitriding, oxidizing and then reducing metal

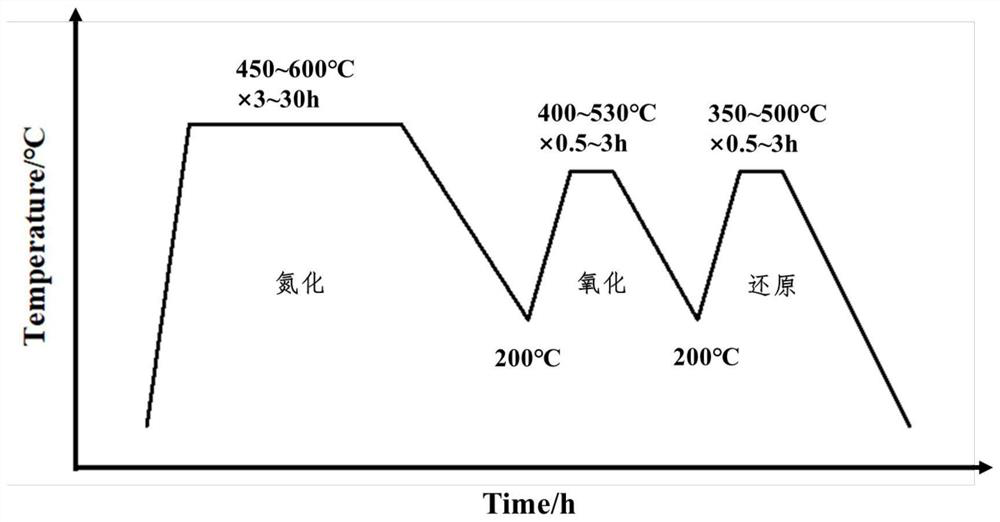

A technology of surface treatment and oxidation treatment, applied in the field of oxidation and then reduction surface treatment and metal nitridation, it can solve the problems of uneven surface color, poor corrosion resistance and high content of the oxide layer, and achieves low oxidation-reduction treatment temperature and improved resistance. Corrosion, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preferred embodiment 1 of the present invention provides a metal nitridation-oxidation-reduction surface treatment method, the treated metal sample is DT4C pure iron, and the method includes the following steps:

[0067] S1 polishes the surface of the sample to make the surface roughness Ra 0.2μm;

[0068] S2 uses anhydrous ethanol for degreasing treatment of the polished sample;

[0069] S3 put the DT4C pure iron sample into the gas nitriding furnace and pass ammonia gas for nitriding treatment. The process parameters of nitriding treatment are: heating rate 10°C / min, nitriding temperature 530°C, nitriding time 10h, then furnace cooling to 200°C and air cooling to room temperature. During the nitriding treatment, the ammonia gas flow was controlled to be 60ml / min, the hydrogen analyzer was turned on at the same time, the ammonia gas decomposition rate was detected, and the ammonia gas decomposition rate in the furnace was controlled to be 35-45%.

[0070] S4 Put the ...

Embodiment 2

[0074] Preferred embodiment 2 of the present invention provides a metal nitridation-oxidation-reduction surface treatment method, the treated metal sample is DT4C pure iron, and the method includes the following steps:

[0075] S1 polishes the surface of the sample to make the surface roughness Ra 0.2μm;

[0076] S2 uses anhydrous ethanol for degreasing treatment of the polished sample;

[0077] S3 put the DT4C pure iron sample into the gas nitriding furnace and pass ammonia gas for nitriding treatment. The process parameters of nitriding treatment are: heating rate 10°C / min, nitriding temperature 530°C, nitriding time 10h, then furnace cooling to 200°C and air cooling to room temperature. During the nitriding treatment, the ammonia gas flow was controlled to be 60ml / min, the hydrogen analyzer was turned on at the same time, the ammonia gas decomposition rate was detected, and the ammonia gas decomposition rate in the furnace was controlled to be 35-45%.

[0078] S4 Put the ...

Embodiment 3

[0082] The preferred embodiment 3 of the present invention provides a metal nitridation-oxidation-reduction surface treatment method, the treated metal sample is DT4C pure iron, and the method includes the following steps:

[0083] S1 polishes the surface of the sample to make the surface roughness Ra 0.2μm;

[0084] S2 uses anhydrous ethanol for degreasing treatment of the polished sample;

[0085] S3 put the DT4C pure iron sample into the gas nitriding furnace and pass ammonia gas for nitriding treatment. The process parameters of nitriding treatment are: heating rate 10°C / min, nitriding temperature 530°C, nitriding time 10h, then furnace cooling to 200°C and air cooling to room temperature. During the nitriding treatment, the ammonia gas flow was controlled to be 60ml / min, the hydrogen analyzer was turned on at the same time, the ammonia gas decomposition rate was detected, and the ammonia gas decomposition rate in the furnace was controlled to be 35-45%.

[0086] S4 put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com