Asphalt modifier for reactive semi-flexible pavement as well as preparation method and application of asphalt modifier

An asphalt modifier and semi-flexible pavement technology, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of difficult to obtain rubber asphalt, long road maintenance period, easy aging and degradation of asphalt, etc. Shorten open traffic time, avoid repeated heating, overcome hard-to-get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the above-mentioned reactive semi-flexible pavement asphalt modifier will be described in detail below, which comprises the following steps:

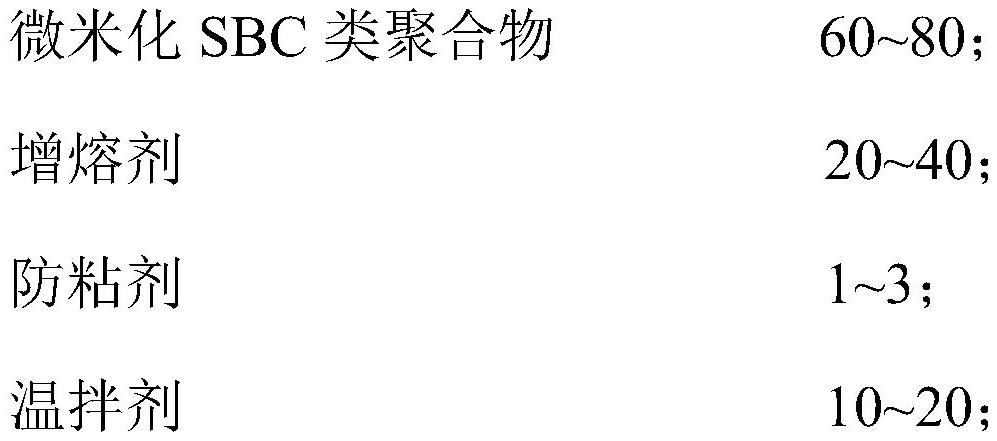

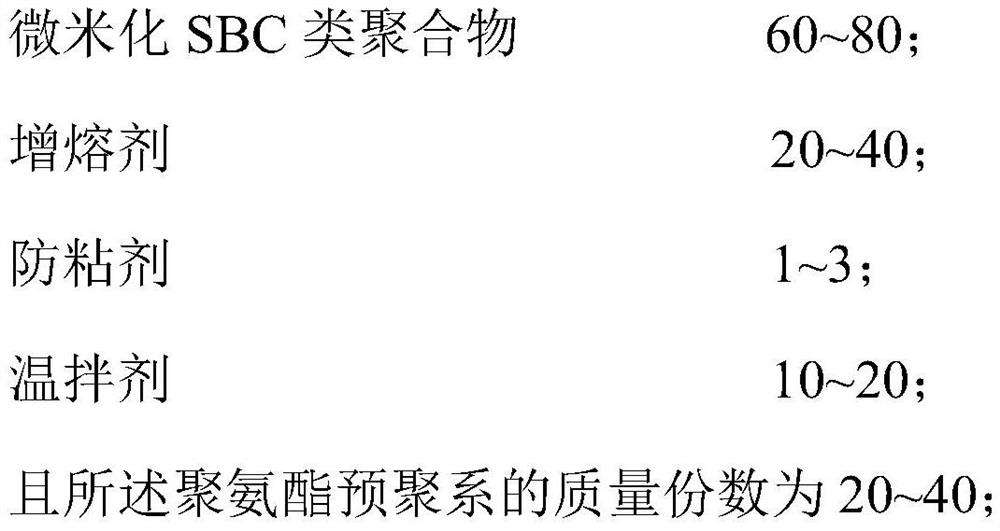

[0045] The preparation steps of the micronized SBC-based mixture: mixing 60-80 parts by mass of the micronized SBC-based polymer, 20-40 parts by mass of a solubilizer, 1-3 parts by mass of a release agent and 10-20 parts by mass of a warm-mixing The mixture is stirred and mixed for 5min-10min to obtain a powdery micronized SBC mixture;

[0046] The preparation steps of the polyurethane prepolymerization system: provide 20-40 parts by mass of the polyurethane prepolymerization system for sealing and preservation;

[0047] The prepared micronized SBC-based mixture and the polyurethane prepolymerization system are stored in a non-contact manner. Therefore, the above-mentioned preparation steps of the micronized SBC-based mixture and the polyurethane prepolymerized system are in no particular order.

[0048...

Embodiment 1

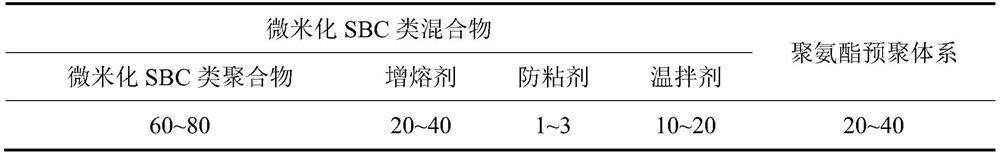

[0055] Table 2 shows the components and their contents of the asphalt modifier provided in this example.

[0056] Table 2 Composition and mass fraction of asphalt modifier for reactive semi-flexible pavement

[0057]

[0058] Wherein, the melting agent is the mixture of DOP and naphthenic oil of equal quality, the anti-sticking agent is talcum powder, and the warm mix agent is pentaerythritol stearate, Fischer-Tropsch wax and polyethylene wax whose mass ratio is 2:1:1 mixture.

[0059] In this embodiment, the particle size of the micronized SBC-based polymer is 60 mesh (ie, 250 μm), and the micronized SBC-based polymer is a mixture of micron SBS and micron SEBS with a mass ratio of 4:1.

[0060] The asphalt modifier in this example was prepared by the following method. On the one hand, firstly, the SBC-based polymer was micronized by a grinding system to obtain a micronized SBC-based polymer (with a particle size of 60 meshes); The parts by mass shown in the above table 2...

Embodiment 2

[0066] Table 3 shows the components and their contents of the asphalt modifier provided in this example.

[0067] Table 3 Composition and mass fraction of asphalt modifier for reactive semi-flexible pavement

[0068]

[0069] Wherein, the melting agent is the mixture of DOP and naphthenic oil whose mass ratio is 1:2, the anti-sticking agent is calcium carbonate, and the warm-mixing agent is pentaerythritol stearate, Fischer-Tropsch, whose mass ratio is 2:0.5:1.5 A mixture of wax and polyethylene wax.

[0070] In this embodiment, the particle size of the micronized SBC-based polymer is 50 meshes (ie, 300 μm), and the micronized SBC-based polymer is a mixture of micron SBS and micron SEBS with a mass ratio of 9:1.

[0071] The asphalt modifier in this example was prepared by the following method. On the one hand, firstly, the SBC-based polymer was micronized by a grinding system to obtain a micronized SBC-based polymer (with a particle size of 50 meshes); The parts by mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com