Adamantyl block type anion exchange membrane and preparation method thereof

An adamantyl block-type, anion-exchange membrane technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problem of AEMs expansion dimensional stability, delayed large-scale anion-exchange membranes, poor alkali durability, etc. Problems, to achieve the effect of good conductivity, high bromination reaction activity, increase density and aggregation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

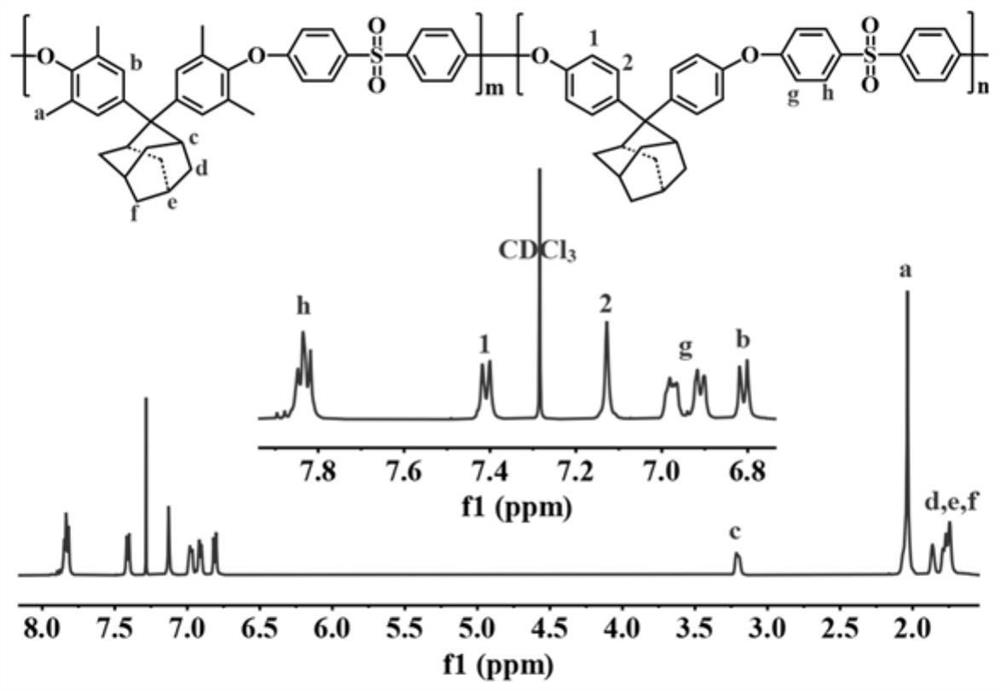

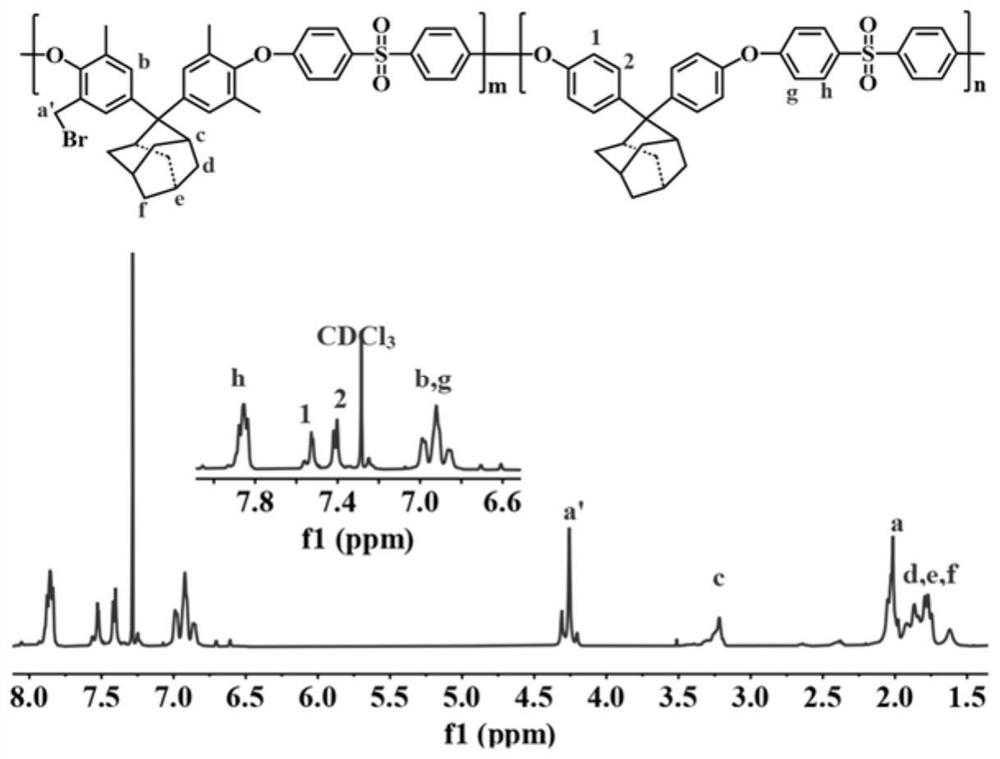

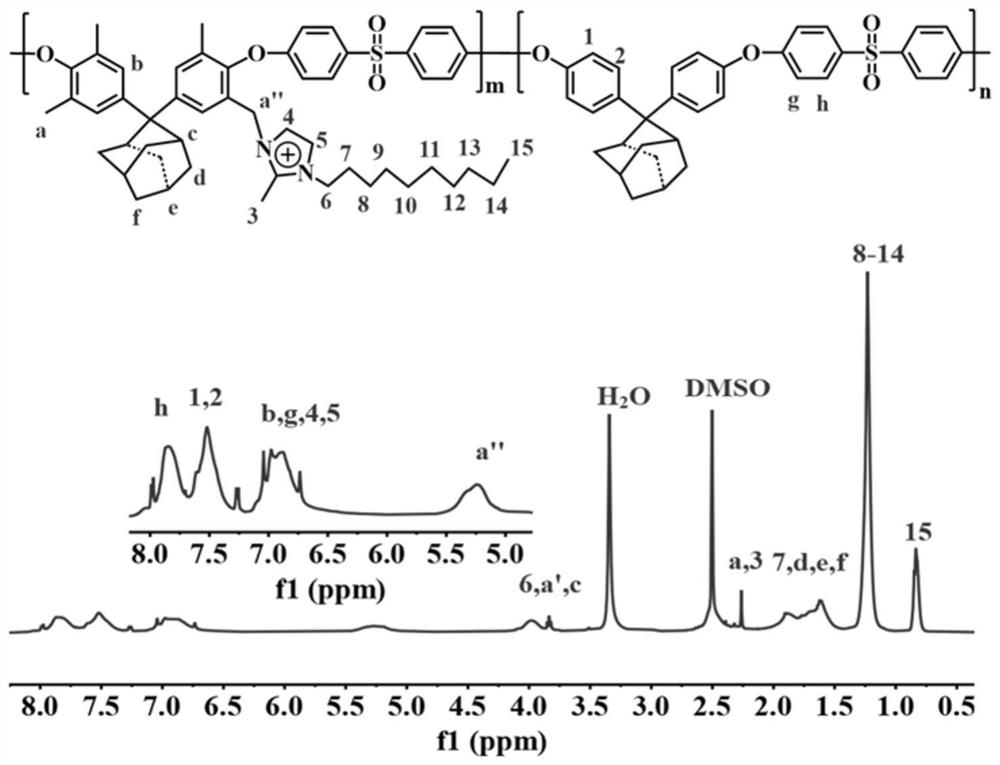

[0048] This embodiment takes the preparation method of synthesizing an adamantyl block type anion exchange membrane with m=10 and n=10 as an example. The structural formula is as follows, and the specific preparation method includes the following steps:

[0049]

[0050] where m=10, n=10, Ar 1 and Ar 2 The structure is a R is H or

[0051] 1) Synthesis of hydrophilic segment: 2,2-bis(2,6-dimethyl-4-hydroxyphenyl)adamantane (MADM) (10mmol, 3.7654g), 4,4'-difluorodiphenyl Sulfone (11 mmol, 2.7967 g), 3.455 g of anhydrous potassium carbonate and 10 mL of toluene were dissolved in 30 mL of N,N-dimethylacetamide, under nitrogen protection, and reacted at 140 °C for 3.5 h, then slowly heated to 160 °C for 20 h, and then Add 4,4'-difluorodiphenylsulfone (0.55mmol, 0.1398g), i.e., 5% (m+1) molar amount, continue the reaction at 160°C for 1h, stop heating, and wait for the reaction system to cool to room temperature naturally. After pouring into methanol aqueous solution for ...

Embodiment 2

[0059] In this example, the preparation method for synthesizing an adamantyl block type anion exchange membrane with m=10 and n=5 is taken as an example. The structural formula is as follows, and the specific preparation method includes the following steps:

[0060]

[0061] where m=10, n=5, Ar 1 The structure is a Ar 2 The structure is a R is H or

[0062] 1) Synthesis of hydrophilic segment: 2,2-bis(2,6-dimethyl4-hydroxyphenyl)adamantane (MADM) (10mmol, 3.7654g), 4,4'-difluorodiphenylsulfone (11mmol, 2.7967g), 3.455g of anhydrous potassium carbonate and 10mL of toluene were dissolved in 30mL of N,N-dimethylacetamide, under nitrogen protection, firstly reacted at 140°C for 3.5h, then slowly heated to 160°C for 20h, and then added 4,4'-Difluorodiphenylsulfone (0.55mmol, 0.1398g), i.e. 5% (m+1) molar amount, continued the reaction at 160°C for 1h, stopped heating, and waited for the reaction system to cool to room temperature naturally, pour the reaction solution int...

Embodiment 3

[0070] In this example, the preparation method for synthesizing an adamantyl block type anion exchange membrane with m=10 and n=15 is taken as an example. The structural formula is as follows, and the specific preparation method includes the following steps:

[0071]

[0072] where m=10, n=15, Ar 1 The structure is a Ar 2 The structure is a R is H or

[0073] 1) Synthesis of hydrophilic segment: 2,2-bis(2,6-dimethyl4-hydroxyphenyl)adamantane (MADM) (10 mmol, 3.7654 g), 4,4'-difluorodiphenylsulfone (11 mmol, 2.7967 g), 3.455 g of anhydrous potassium carbonate and 10 mL of toluene were dissolved in 30 mL of N,N-dimethylacetamide under nitrogen protection, and then reacted at 140 °C for 3.5 h, then slowly heated to 160 °C for 20 h, and then added 4,4'-Difluorodiphenylsulfone (0.55mmol, 0.1398g), i.e. 5% (m+1) molar amount, continued the reaction at 160°C for 1h, stopped heating, and waited for the reaction system to cool to room temperature naturally, pour the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com