Phenolphthalein-based anion exchange membrane containing comb-shaped side chains and preparation method thereof

An anion-exchange membrane, phenolphthalein-based technology, applied in the field of alkaline fuel cells, to overcome high ionic conductivity, enhance water retention capacity and anti-swelling performance, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

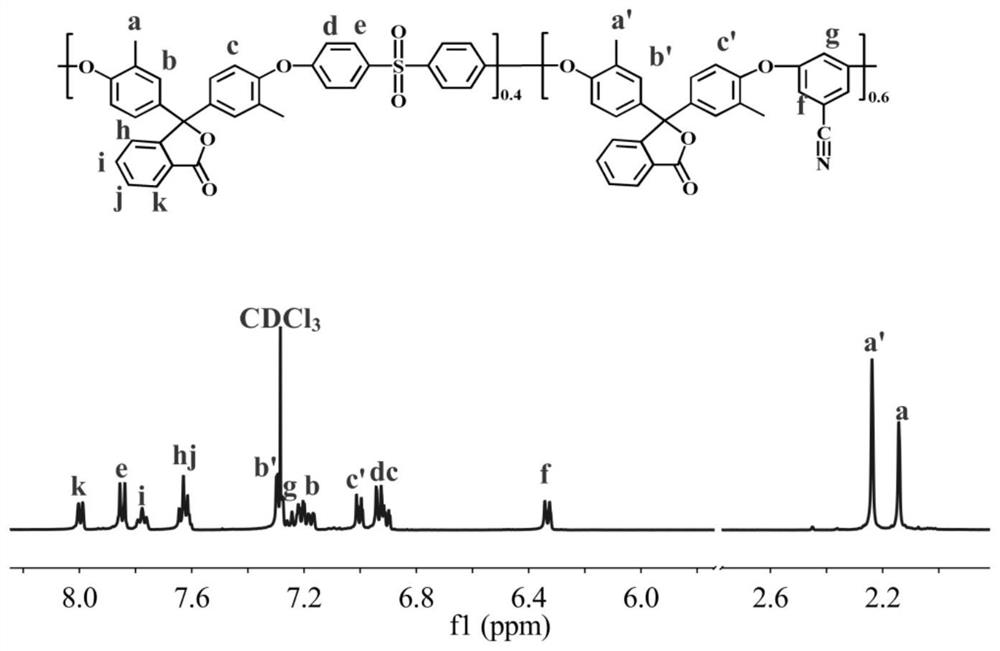

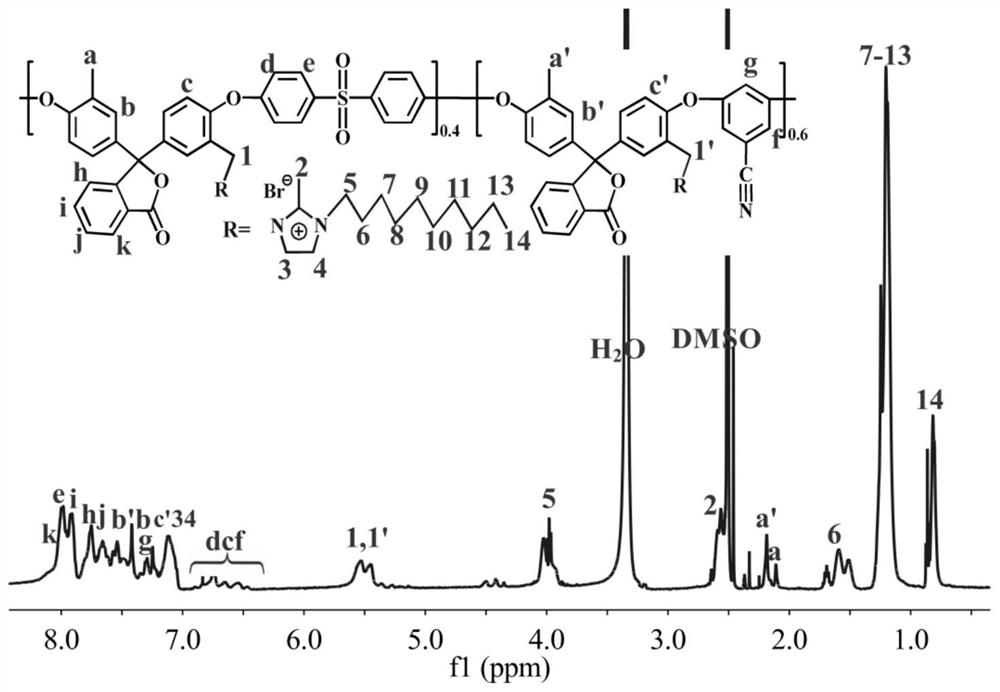

[0045] In this embodiment, the long carbon chain comb-shaped phenolphthalein-based polyarylethersulfone nitrile anion exchange membrane containing 10 carbon atoms (the proportion of sulfone segments is 40%) is taken as an example, and the structural formula is as follows:

[0046]

[0047] where R is H or Concrete preparation method comprises the following steps:

[0048] 1) Polymer synthesis: 1.149g 4,4'-dichlorodiphenylsulfone (4mmol), 1.032g 3,5-dichlorobenzonitrile (6mmol), 3.465g o-cresolphthalein (10mmol), 3.784g (27.4 mmol) of anhydrous potassium carbonate and 10 mL of toluene were dissolved in 30 mL of N,N-dimethylacetamide, protected by nitrogen, and reacted at 145°C for 4 hours, then heated to 170°C for 20 hours, and cooled with 400mL of aqueous methanol (methanol and water) The volume ratio is 1:1) to precipitate, filter, wash, and dry to obtain a phenolphthalein-based polymer.

[0049] 2) Synthesis of bromomethylated polymer: Dissolve 1 g (2.04 mmol) of pheno...

Embodiment 2

[0053] In this embodiment, the long carbon chain comb-shaped phenolphthalein-based polyarylether ketone nitrile anion exchange membrane containing 10 carbon atoms (the ratio of the ketone segment is 20%) is taken as an example, and the structural formula is as follows:

[0054]

[0055] where R is H or Concrete preparation method comprises the following steps:

[0056] 1) Synthesis of phenolphthalein-based polyarylether ketone nitrile polymer: 3,5-dichlorobenzonitrile (8mmol, 1.376g), o-cresolphthalein (10mmol, 3.465g), 4,4'-dichlorobenzophenone (2mmol, 0.5024g), 3.932g (28.4mmol) anhydrous potassium carbonate, and 10mL toluene, dissolved in 30mL polar aprotic solvent N,N-dimethylformamide, under nitrogen protection, reacted at 145°C for 4h, Then heat up to 170°C to react for 20h, and after cooling, precipitate with 400mL methanol aqueous solution (the volume ratio of methanol to water is 1:1), filter, wash, and dry to obtain polyaryletherketonenitrile polymer.

[0057] ...

Embodiment 3

[0061] In this embodiment, the long carbon chain comb-shaped phenolphthalein-based polyarylether ketone nitrile anion exchange membrane containing 12 carbon atoms (the ratio of the ketone segment is 40%) is taken as an example, and the structural formula is as follows:

[0062]

[0063] where R is H or Concrete preparation method comprises the following steps:

[0064] 1) Synthesis of phenolphthalein-based polymers: 4,4'-dichlorobenzophenone (4mmol, 1.004g), 3,5-dichlorobenzonitrile (6mmol, 1.032g), o-cresolphthalein (10mmol, 3.465g ), 3.452g (25mmol) of anhydrous potassium carbonate and 10mL of toluene were dissolved in 30mL of N,N-dimethylacetamide, protected by nitrogen, and reacted at 145°C for 4h, and then heated to 170°C for 20h, cooled and washed with 400mL of methanol The aqueous solution (the volume ratio of methanol to water is 1:1) is precipitated, filtered, washed and dried to obtain polyaryletherketonenitrile polymer.

[0065] 2) Synthesis of bromomethylated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com