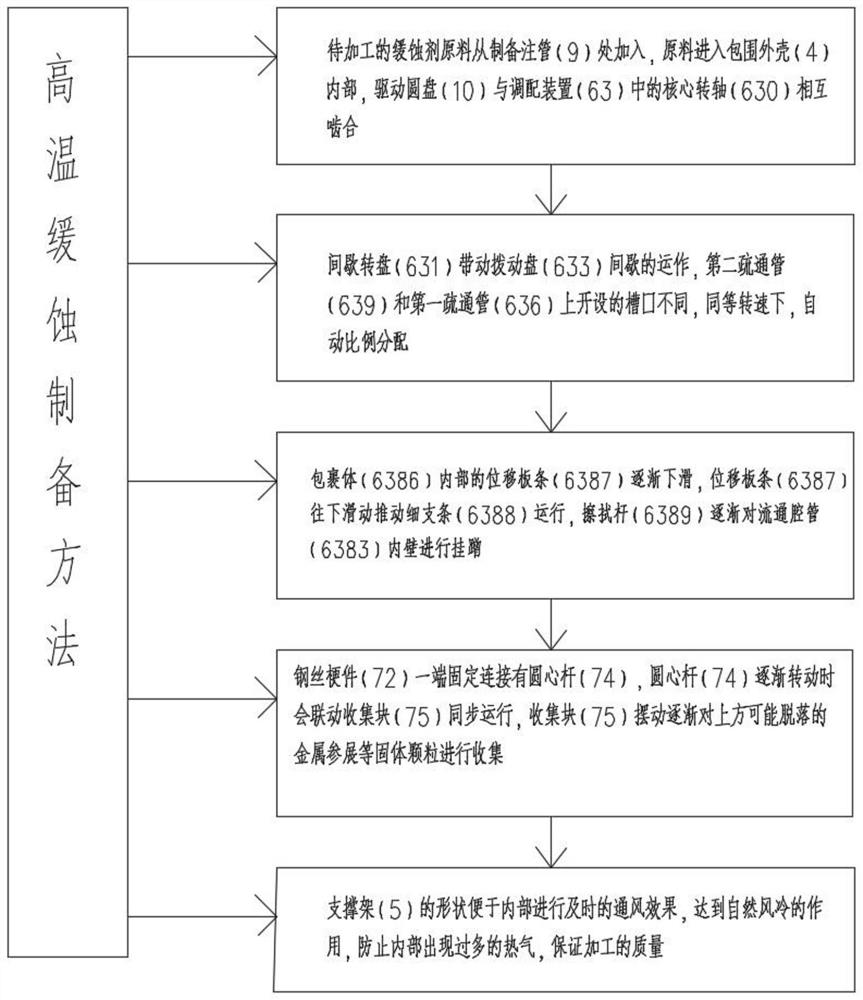

Preparation device and preparation method of high-temperature corrosion inhibitor

A technology for high temperature corrosion inhibitor and preparation device, which is applied in chemical instruments and methods, earthwork drilling, transportation and packaging, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

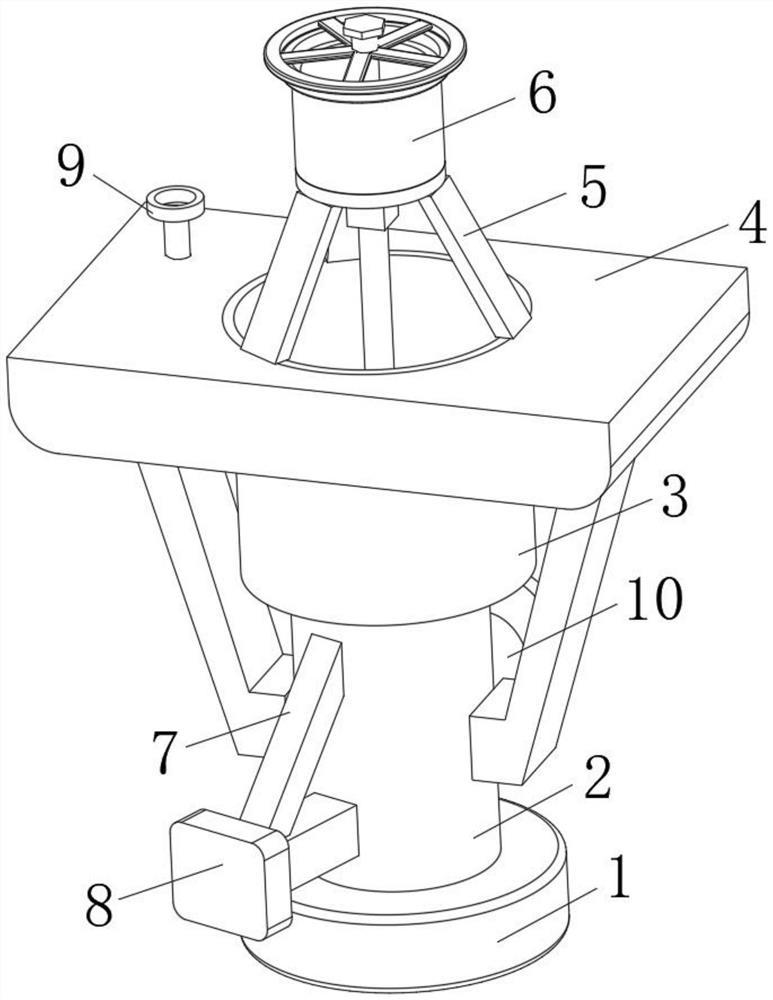

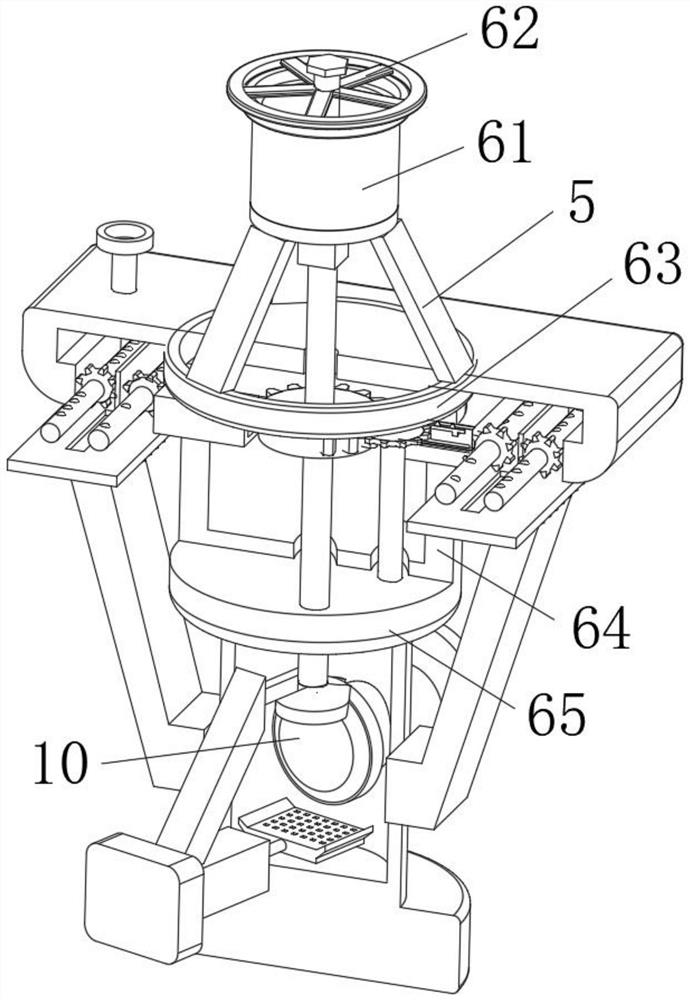

[0035] see Figure 2-Figure 10 , the present invention provides a technical solution: a high-temperature corrosion inhibitor preparation device, comprising a metal base 1, the top of the metal base 1 is fixedly connected with a support column 2, the top of the support column 2 is fixedly connected with a mixing pipe 3, and the top of the mixing pipe 3 is fixed The surrounding shell 4 is connected, the middle part of the upper surface of the surrounding shell 4 is fixedly connected with a support frame 5, and the top end of the support frame 5 is fixedly connected with a mixing device 6. the technological purpose of the operation;

[0036] The mixing device 6 includes a circular cylindrical member 61, the top of the circular cylindrical member 61 is movably connected with a swinging disc 62, and the bottom end of the support frame 5 is fixedly connected with a dispensing device 63. The bottom of the dispensing device 63 is fixedly connected with a container cavity 64, and the ...

Embodiment 2

[0042] see Figure 1-Figure 5 , the present invention provides a technical solution: on the basis of the first embodiment, a preparation injection pipe 9 is fixedly connected to the left side of the upper surface of the surrounding casing 4 , and the preparation injection pipe 9 penetrates the surrounding casing 4 and extends to the inner cavity of the surrounding casing 4 , The outer surface of the support column 2 is fixedly connected with an anti-falling device 7. Through the setting of the anti-falling device 7, it is ensured that there will not be too much falling off metal iron filings inside, and the effect of promoting the internal processing quality is achieved, and the purity of the equipment is improved. The anti-falling device The front surface of 7 is fixedly connected with a combination button disc 8 , and the back of the support column 2 is fixedly connected with a driving disc 10 , and the driving disc 10 penetrates the support column 2 and extends to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com