A mine rope changing automatic rope winding machine and its use method

A rope winding and automatic technology, which is applied in mine lifting equipment, transportation and packaging, etc., can solve the problems of long duration, slow winding rope recovery, high operating intensity, etc., to achieve automatic operation and solve the winding rope recovery speed Slow, the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

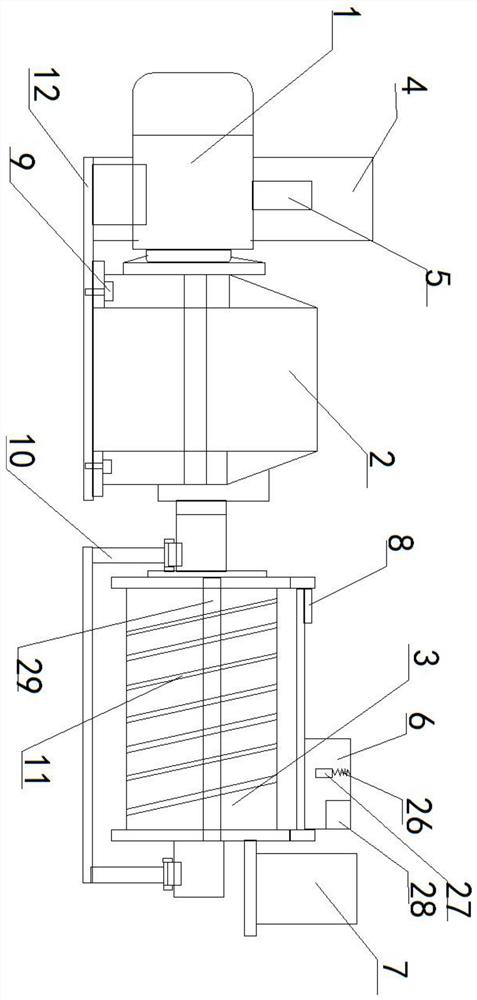

[0022] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a kind of mine rope changing automatic rope winding machine is characterized in that, comprises base 12, roller 3, roller bracket 10, and described roller bracket 10 is fixedly connected on described base 12, and described roller 3 The shaft passing through the inner cavity of the roller 3 is connected to the roller bracket 10, the base 12 is fixedly connected with the motor 1 and the reduction box 2 by bolts, the motor 1 and the reduction box 2 are connected through gears, and the roller The cylinder 3 is connected with the reduction box 2 through a transmission shaft, the oil injection device 6 and the emergency rope clamping device 29 are arranged on the roller bracket 10, a rope fixing device 7 is arranged on one side of the roller bracket 10, and the roller The other side of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com