Dust removal unit

A driven shaft and base plate technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of multiple processing and assembly procedures, low efficiency, complex and cumbersome processes, etc., and achieve the effect of reasonable structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

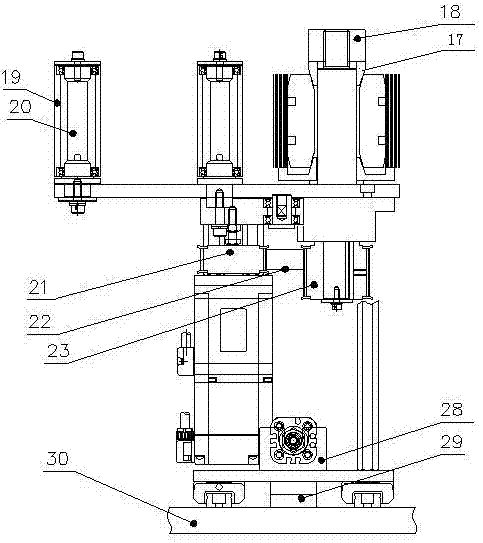

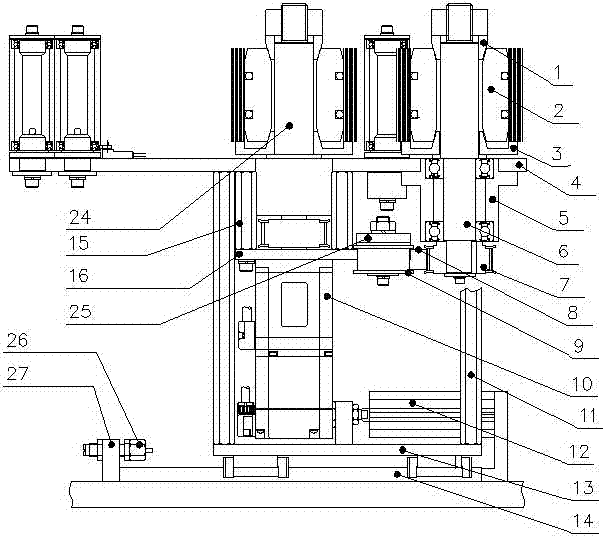

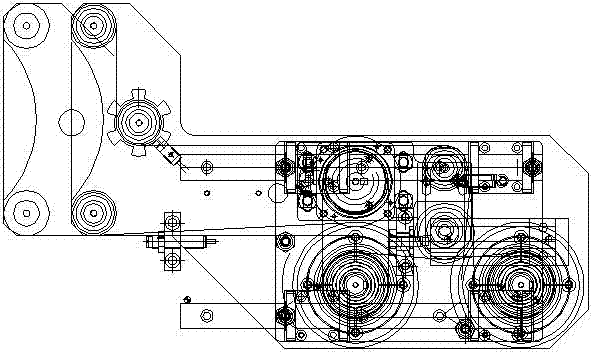

[0020] A dust removal unit: In the schematic structural diagram, it is divided into three parts: a tape clamping mechanism, a tape roller transmission mechanism and a dust removal driving mechanism, all of which are fixed on the base plate 30 of the equipment machine. The tape clamping mechanism includes a bottom plate 13 provided with installation references for various parts. The support plate 4 is mounted on the bottom plate 13 by a bracket 11, and the bearing seat 5 supporting the first driven shaft 6 is fixed under the support plate 4. The sleeve 2 is installed on the first driven shaft 6, the clamp base 3 and the tension sleeve 1 are installed on the two ends of the sleeve 2 on the first driven shaft 6, and the lock nut 18 is installed on the shaft end of the first driven shaft 6. At the thread, the fixed handle 17 is installed on the lock nut 18, and the third driven wheel 19 is fixed to the support plate 4 by the fourth driven shaft 20; the belt roller transmission mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com