Full-ceramic heating body

A ceramic heating element and heating layer technology, applied in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve problems such as poor temperature control accuracy, and achieve reliable life, accurate and reliable temperature, rapid response and real-time changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

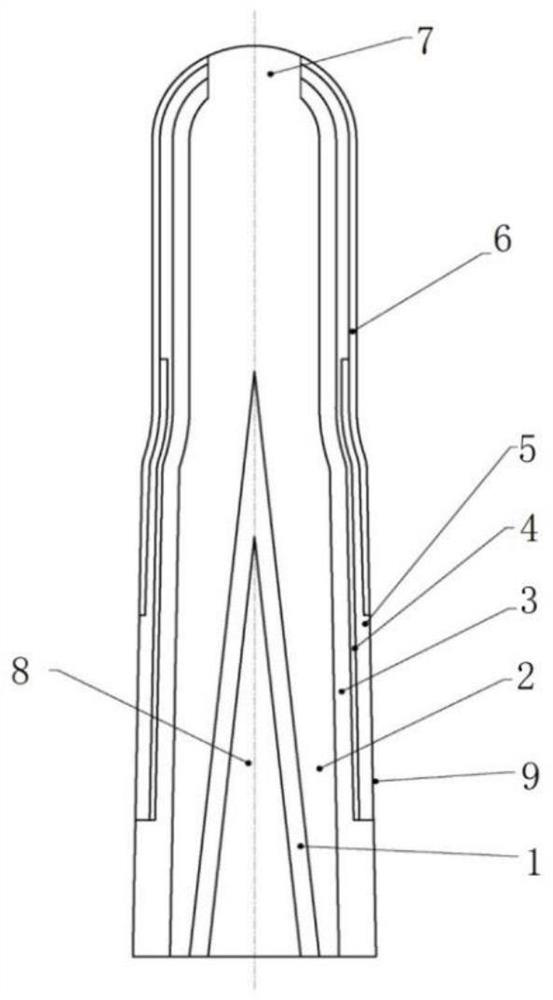

[0022] like figure 1 As shown, an all-ceramic heating body, from the inside to the outside, is an inner conductive layer 1, an inner resistance layer 2, an inner insulating layer 3, an outer resistance layer 4, an outer conductive layer 5 and an outer insulating layer 6. The inner conductive layer 1 is located in the innermost part of the electric heating body, the center of the bottom end of the inner conductive layer 1 is the center electrode welding place 8, the inner resistance layer 2 is divided into two sections, the diameter of the lower end is larger than the diameter of the upper end, and the lower end of the inner resistance layer 2 is wrapped. Outside the inner conductive layer 1; the inner insulating layer 3 is divided into three sections, the diameter of the middle section is larger than the diameter of the upper section, the diameter of the lower section is larger than the diameter of the middle section, and the upper section is wrapped outside the upper section ...

Embodiment 2

[0031] With reference to the all-ceramic heating element of Example 1, the difference is:

[0032] The weight ratio of the ceramic materials of the outer resistance layer 4 is: silicon nitride: silicon carbide: aluminum oxide: yttrium oxide: lanthanum oxide: molybdenum disilicide=660:260:70:80:20:700.

[0033] The weight ratio of the ceramic materials of the internal resistance layer 2 is: silicon nitride: silicon carbide: aluminum oxide: yttrium oxide: lanthanum oxide: molybdenum disilicide=550:110:50:55:10:550.

[0034] The weight ratio of the ceramic material of the outer insulating layer 6 is: silicon nitride: aluminum oxide: yttrium oxide: molybdenum disilicide=680:70:80:700.

[0035] The weight ratio of the ceramic materials of the inner insulating layer 3: silicon nitride: aluminum oxide: yttrium oxide: lanthanum oxide: molybdenum disilicide=680:45:80:20:50.

[0036] The weight ratio of the ceramic materials of the outer conductive layer 5: silicon nitride: aluminum ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com