Distributed hydrogen production energy storage power generation system and working method thereof

A power generation system, distributed technology, applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of fuel cell system complexity and auxiliary power consumption increase, to shorten the start-up time, reduce production costs, and ensure normal start-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

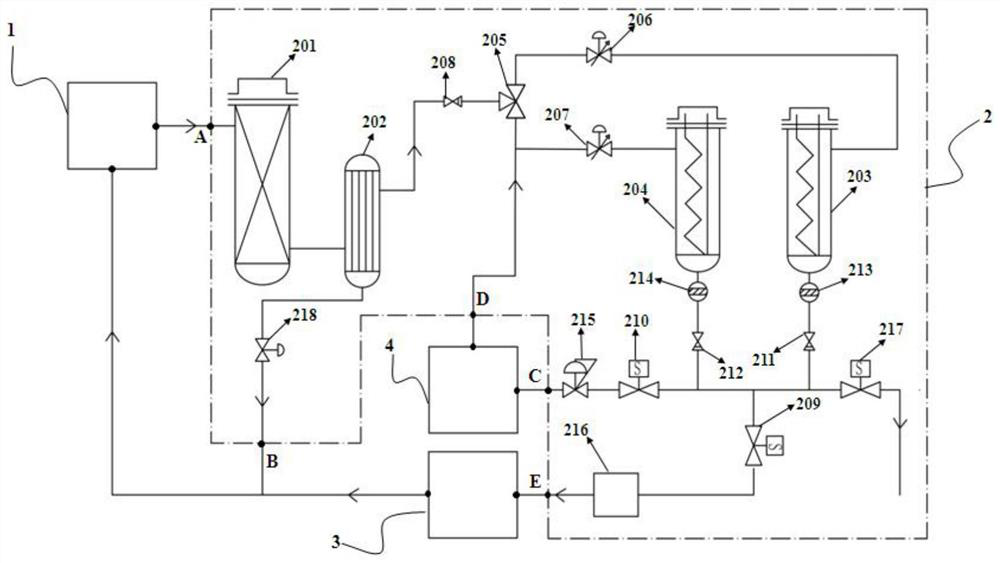

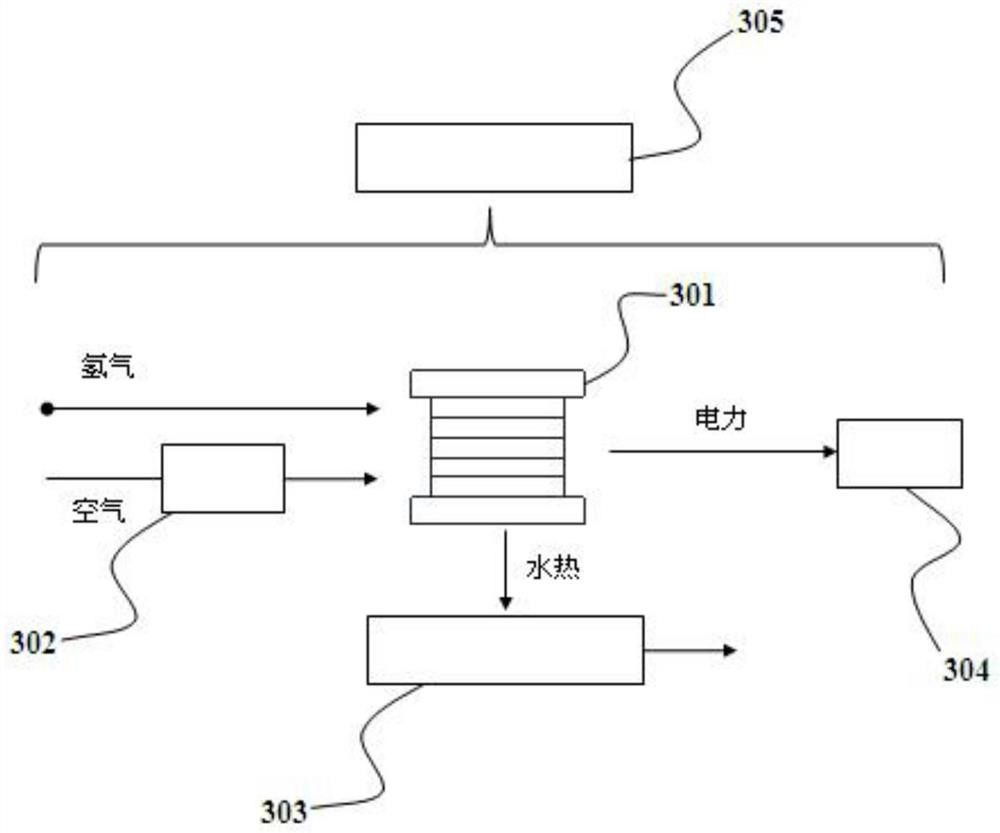

[0034] see figure 1 The distributed hydrogen production and energy storage power generation system provided in this embodiment includes a water electrolysis hydrogen production unit 1, a hydrogen purification and humidification unit 2, a fuel cell power generation unit 3, and a solid-state hydrogen storage unit 4. The water electrolysis hydrogen production unit 1 passes through a pipe The road is connected to the hydrogen purification and humidification unit 2, the hydrogen purification and humidification unit 2 is connected to the fuel cell power generation unit 3 and the solid-state hydrogen storage unit 4 through the pipeline, and the fuel cell power generation unit 3 is connected to the water electrolysis hydrogen production unit 1 through the pipeline.

[0035] The water electrolysis hydrogen production unit 1 has a power supply system and a water electrolysis hydrogen production device, and the power supply system is one or a combination of a renewable energy power genera...

Embodiment 2

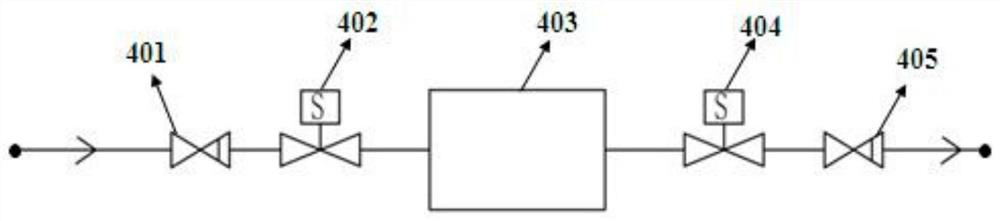

[0055] refer to Figure 4 The difference between the distributed hydrogen production and energy storage power generation system provided in this embodiment and the first embodiment is only that the structure of the solid-state hydrogen storage unit 4 is changed. In this embodiment, a hydrogen storage device 403 and a tee are added to the solid-state hydrogen storage unit 4 Valve 406, and the fourth solenoid valve 402 is also added by one, and the fifth solenoid valve 404 is removed. Adding the hydrogen storage device 403 can increase the hydrogen storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com