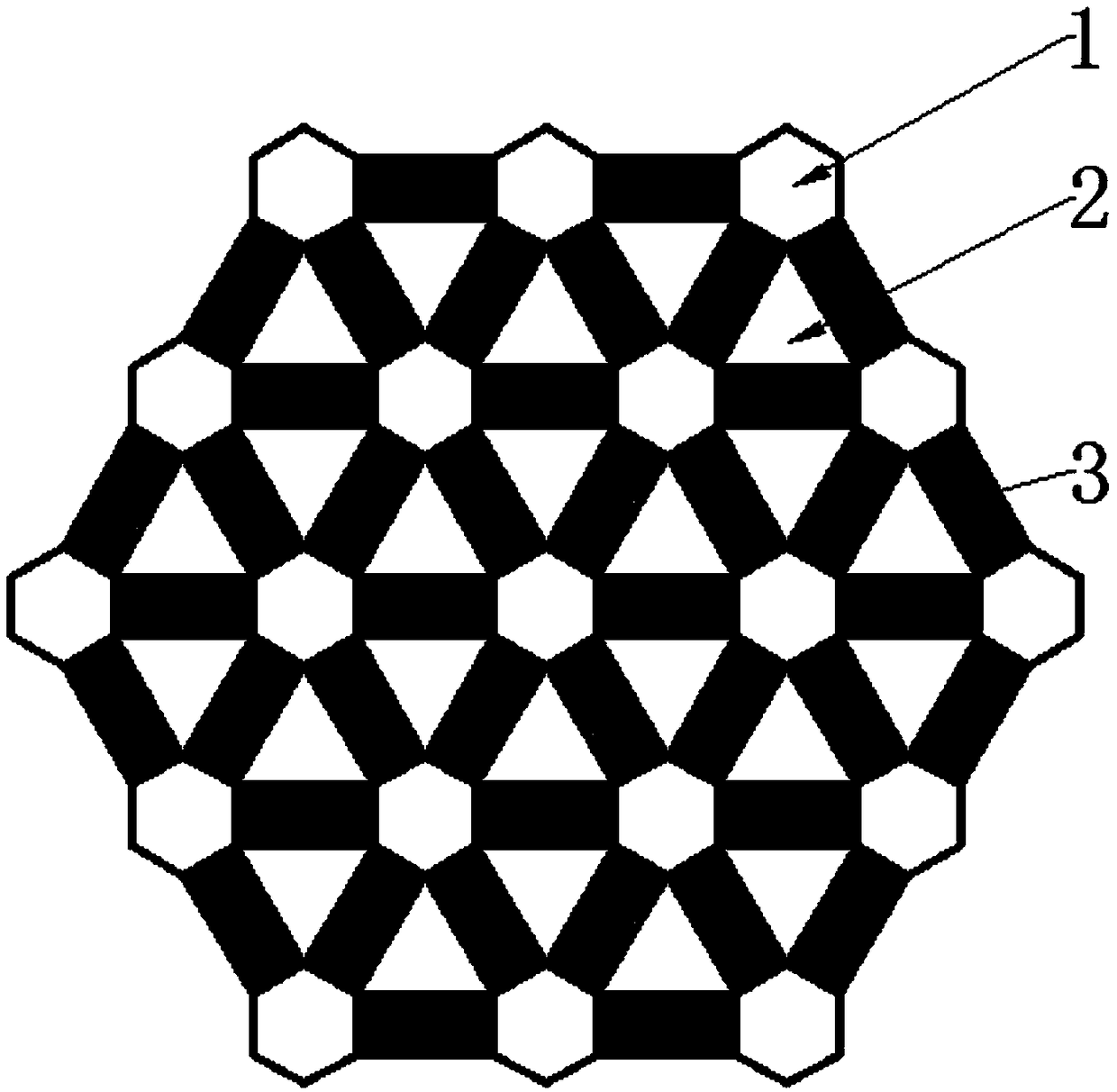

Asymmetric filter tunnel structure of grain catcher

A particle filter and pore structure technology, applied in dispersed particle filtration, membrane filter, gas treatment and other directions, can solve problems such as affecting the performance of diesel engines, shortening the service life of the particle filter, increasing the regeneration frequency and increasing the cost of post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

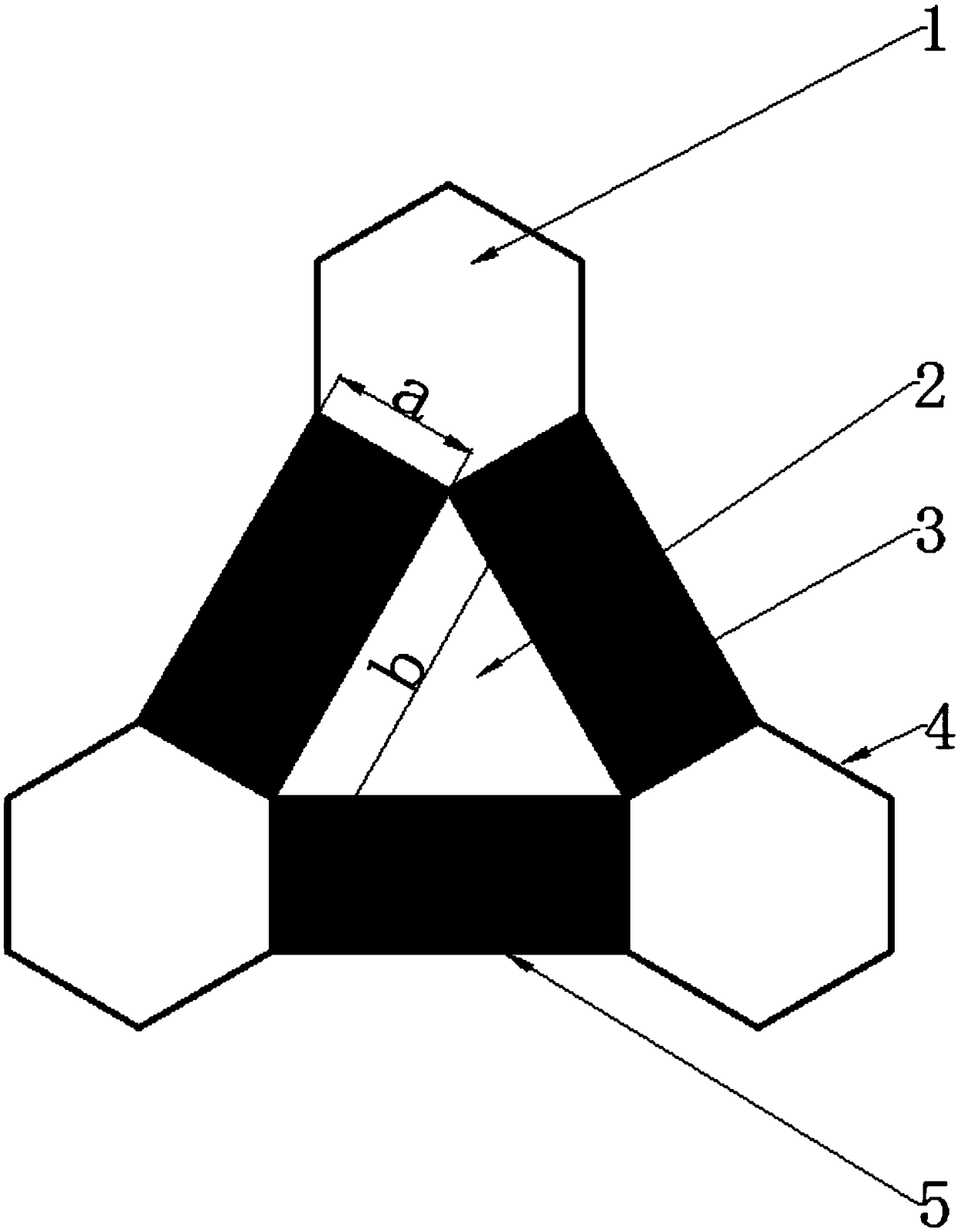

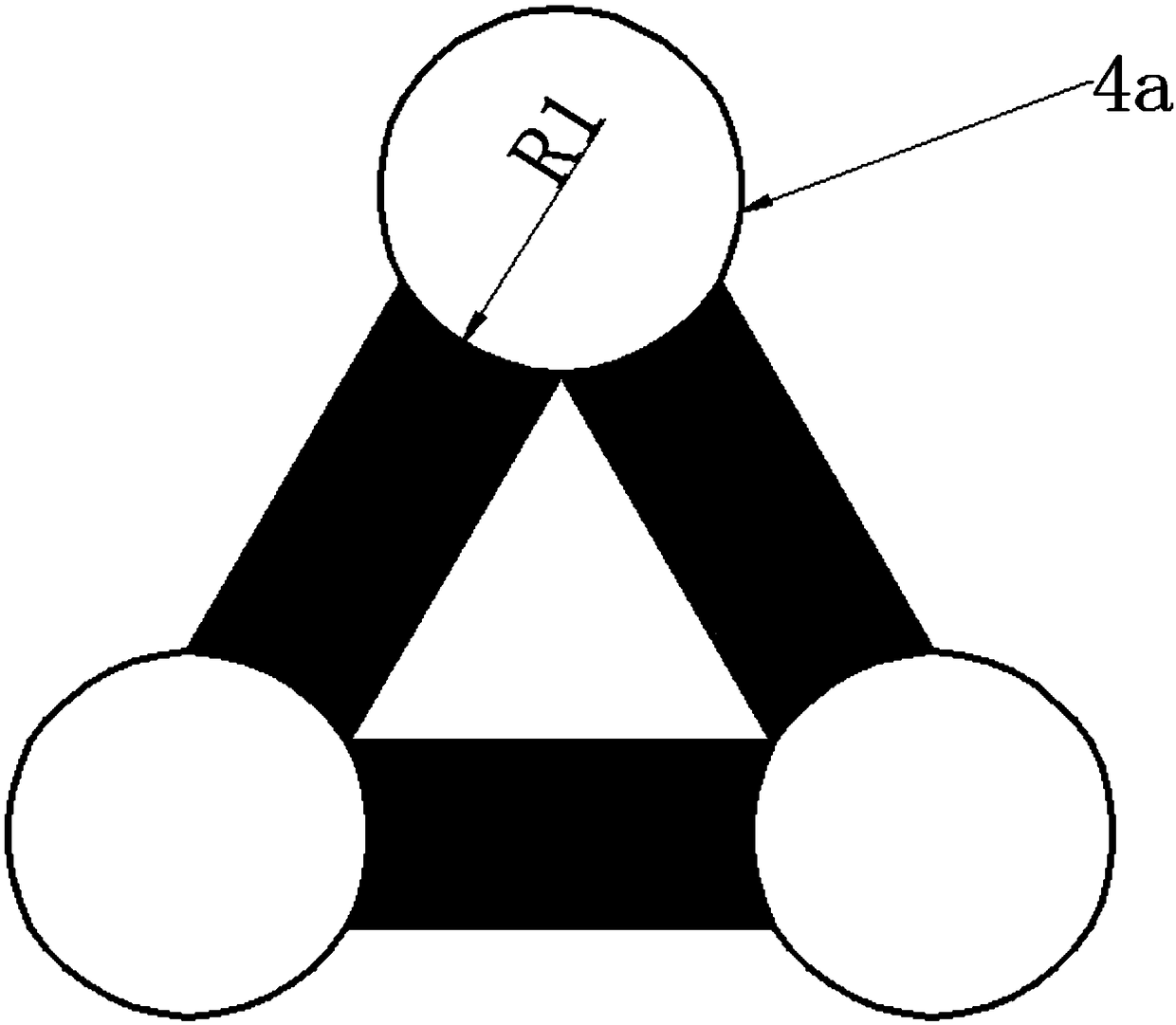

[0038] Such as Figure 3-5As shown, the hexagonal channel wall 4 and the triangular channel wall 5 are replaced by the curved channel wall 4a. The hexagonal channel wall 4 and the triangular channel wall 5 can be replaced separately or at the same time. The radii R1 and R2 of the curved channel wall 4a can be adjusted.

Embodiment 2

[0040] Such as Figure 6-8 As shown, the hexagonal channel wall 4 and the triangular channel wall 5 are replaced by the curved channel wall 4b. The hexagonal channel wall 4 and the triangular channel wall 5 can be replaced separately or at the same time. The angles A1 and A2 of the zigzag channel wall 4b can be adjusted.

[0041] It is also possible to replace the sides of the hexagonal channel with outwardly convex broken lines, and the sides of the triangular channel with outwardly convex curves. Or replace the sides of the hexagonal channels with outwardly convex curves, and replace the sides of the triangular channels with outwardly convex broken lines. The above embodiment adopts the convex curved channel wall 4a and the broken line channel wall 4b to further expand the volume of the inlet channel, increase the area of the filter wall, and effectively improve the performance of the particle filter with an asymmetric channel structure.

[0042] The asymmetric pore stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com