Printing and dyeing wastewater deep treatment method and equipment

A technology for advanced treatment of printing and dyeing wastewater, applied in textile industry wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of limited water quality improvement, achieve low cost, improve use efficiency, and reduce adsorption load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

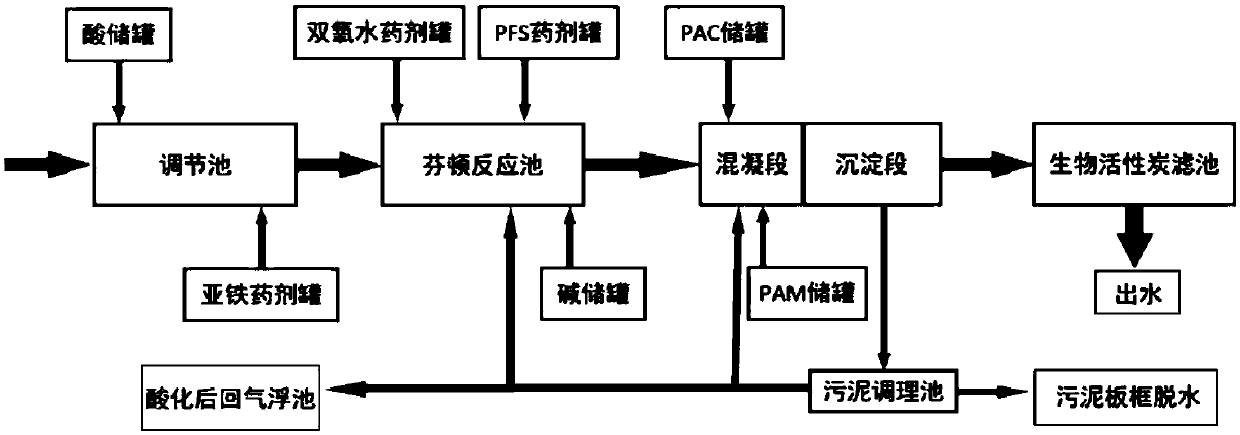

[0027] refer to figure 1 , In one embodiment, an advanced treatment equipment for printing and dyeing wastewater, including a Fenton / coagulation / sedimentation system and a biological activated carbon filter.

[0028] The Fenton / coagulation / sedimentation system includes a regulating tank, a Fenton reaction tank and a sedimentation tank, the pH is adjusted before the Fenton reaction in the regulating tank, and the catalyst is added at the tail end of the regulating tank; Hydrogen peroxide is added in the early stage of the Fenton reaction tank, PFS is added in the middle and late stages of the Fenton reaction tank according to the water quality conditions, and lye is added at the end of the Fenton reaction tank to adjust the pH of the effluent; in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com