Stage treatment type magnetic filter device

A graded treatment and magnetic filtration technology, which is applied in the metallurgical field, can solve problems such as poor scraping effect, scraper wear, and increased difficulty, and achieve the effects of reducing adsorption load, reducing maintenance costs, and reducing adsorption load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

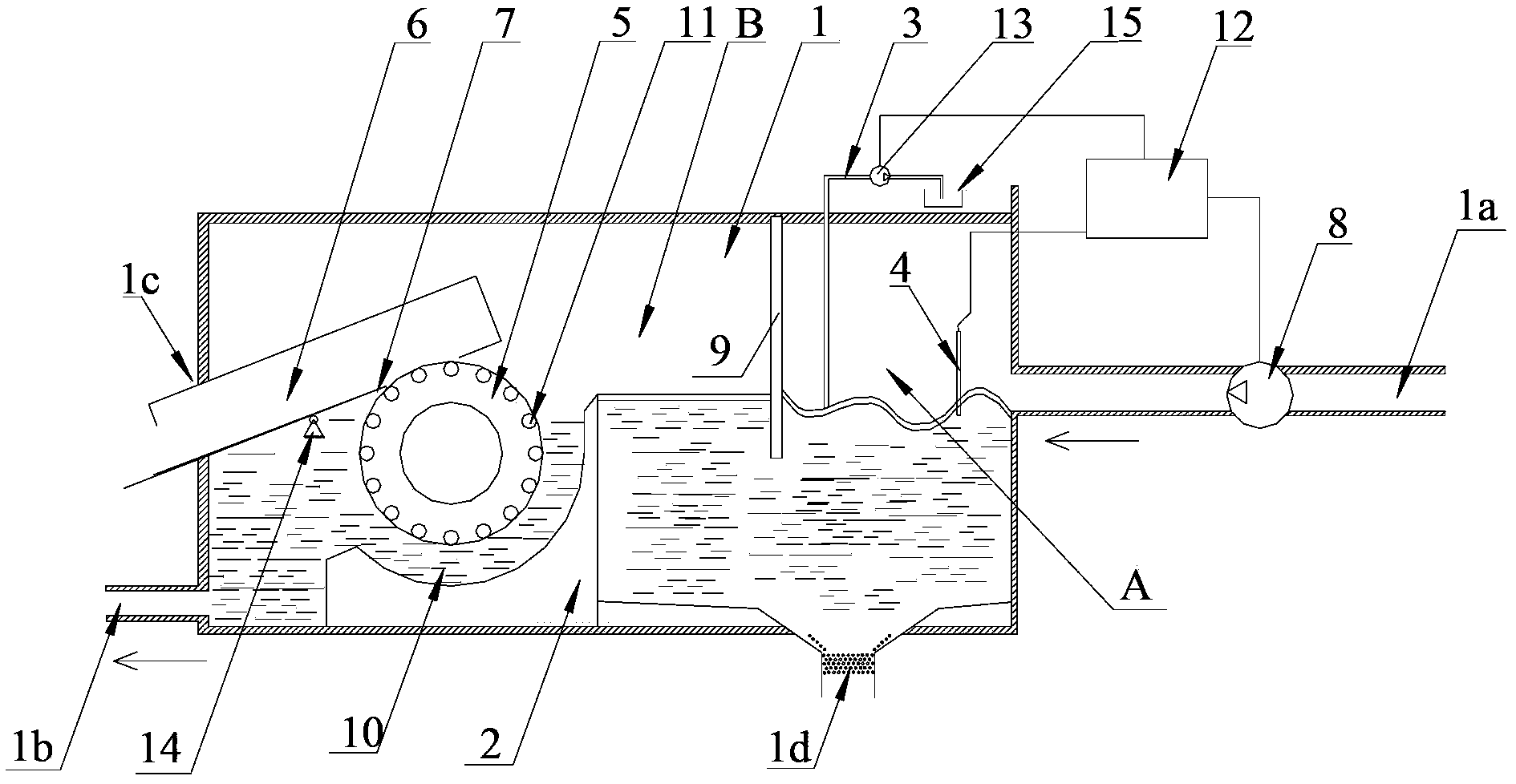

[0014] figure 1 The graded treatment magnetic filtration device shown in includes a liquid storage tank 1, which is divided into a filtrate pretreatment area A and a filtrate magnetic adsorption area B by a clear liquid overflow plate 2.

[0015] A filtrate inlet 1a is provided on the outer upper part of the filtrate pretreatment area A, and a sediment discharge port 1d is provided at the bottom of the filtrate pretreatment area A. At the same time, the bottom of the filtrate pretreatment area A has a wedge-shaped structure of 10-15° centered on the sediment discharge port 1d. The filtrate is placed in the pretreatment area for precipitation, so that the ferromagnetic substances in it accumulate towards the sediment discharge port 1d, and the staff regularly conduct slagging operations through the sediment discharge port 1d, or use ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com