Coarse brine for electrolysis impurity removal treatment device and treatment method thereof

A treatment device and brine technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high content, poor brine quality, and high production costs, and improve brine quality. The effect of quality, lower production cost and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, as attached figure 1 As shown, the coarse brine impurity removal treatment device for electrolysis includes a crude brine baffle tank 1, a crude brine tank 2, a pressurized container tank 3, a preprocessor 4, a reaction tank 5, a brine buffer tank 6, and a membrane filter 7 , refined brine deflection tank 8 and refined brine tank 9; a saturated coarse brine pipeline 10 is fixedly connected to the liquid inlet end of the crude brine deflection tank 1, and a corresponding pipe is fixedly installed above the coarse brine deflection tank 1 through a bracket respectively The corresponding alkali pipeline 11 and the secondary sodium pipeline 12, the liquid outlet end of the crude brine baffle tank 1 and the liquid inlet end of the crude brine tank 2 are fixedly connected together through the first pipeline 13, and the liquid outlet end of the crude brine tank 2 and the feeder The liquid inlet end of the pressure vessel tank 3 is fixedly connected together throug...

Embodiment 2

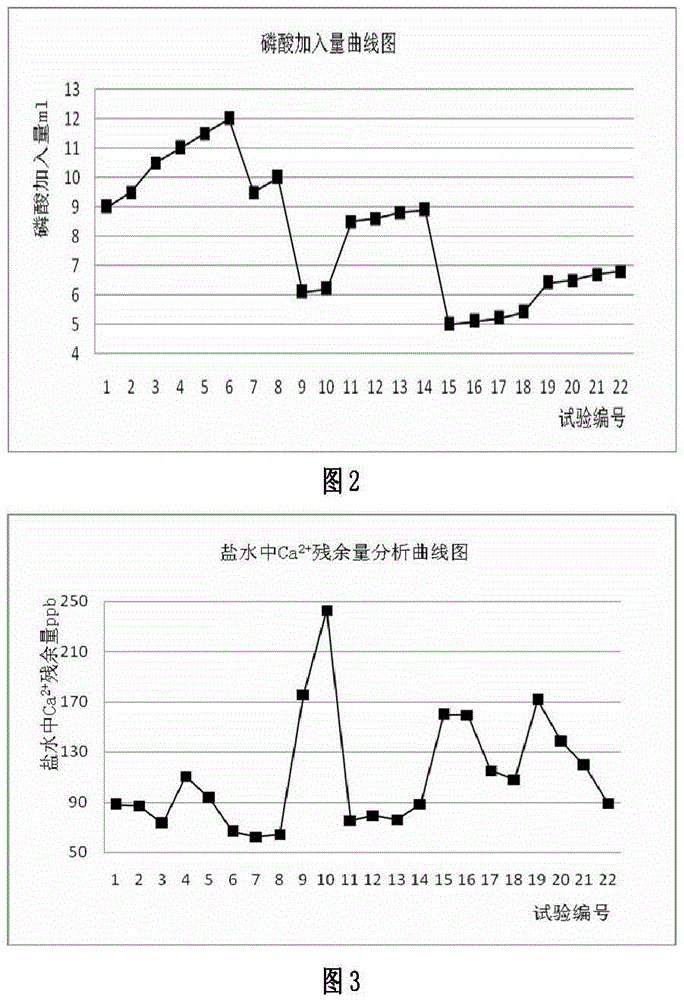

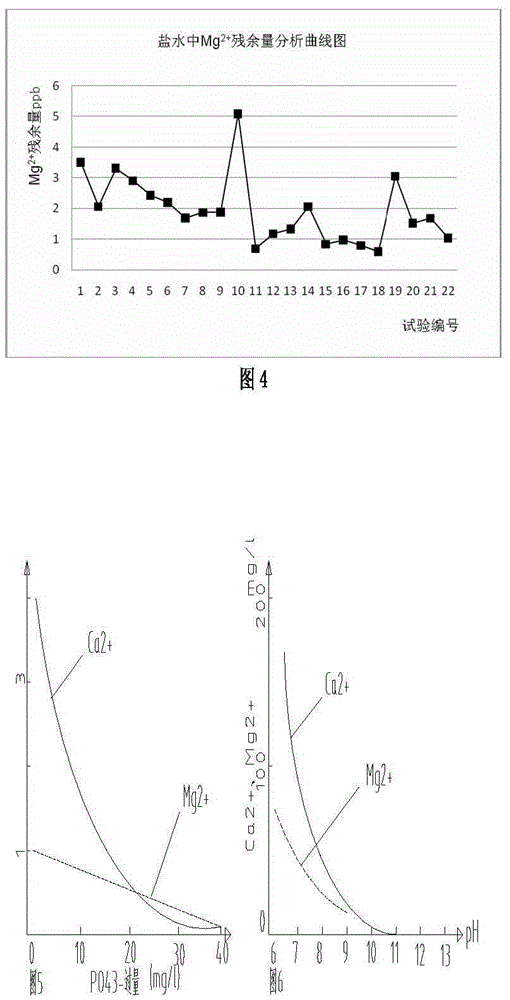

[0032] Embodiment 2, as attached figure 1 As shown, the treatment method using the electrolytic crude brine impurity removal treatment device is carried out according to the following steps: first step, the saturated crude brine with a temperature of 55°C to 65°C is passed through the saturated crude brine pipeline 10 into the crude brine for deflection In the tank 1, an aqueous sodium hydroxide solution is added to the crude brine deflection tank 1 through the alkali pipeline 11, and an aqueous sodium hypochlorite solution is added to the crude brine deflection tank 1 through the hyposodium pipeline 12, and the saturated crude brine and the aqueous sodium hydroxide solution and the aqueous sodium hypochlorite solution are added. After reacting in the crude brine baffle tank 1, enter the crude brine tank 2 through the first pipeline 13, the addition of the aqueous sodium hydroxide solution makes the excess alkalinity of sodium hydroxide in the crude brine of the crude brine tan...

Embodiment 3

[0033] Embodiment 3, as attached figure 1 As shown, the treatment method using the electrolytic crude brine impurity removal treatment device is carried out according to the following steps: first step, the saturated crude brine with a temperature of 50°C or 65°C is passed through the saturated crude brine pipeline 10 into the crude brine for deflection In the tank 1, an aqueous sodium hydroxide solution is added to the crude brine deflection tank 1 through the alkali pipeline 11, and an aqueous sodium hypochlorite solution is added to the crude brine deflection tank 1 through the hyposodium pipeline 12, and the saturated crude brine and the aqueous sodium hydroxide solution and the aqueous sodium hypochlorite solution are added. After reacting in the crude brine baffle tank 1, enter the crude brine tank 2 through the first pipeline 13, the addition of the aqueous sodium hydroxide solution makes the excess alkalinity of sodium hydroxide in the crude brine of the crude brine tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com