Prestressed post-inserted composite anchor cable uplift pile and on-site loading equipment thereof

A technology of prestressed and pull-resistant piles, which is applied in the test of sheet pile walls, buildings, and foundation structures, etc., to achieve the effects of reducing inclination and position deviation, eliminating tensile stress, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

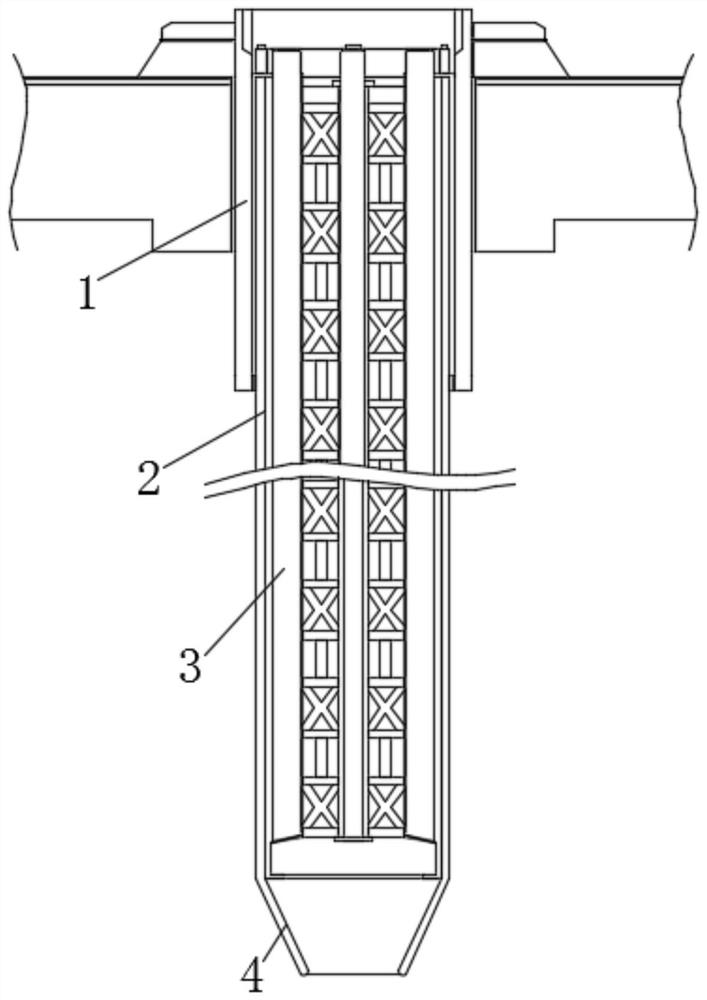

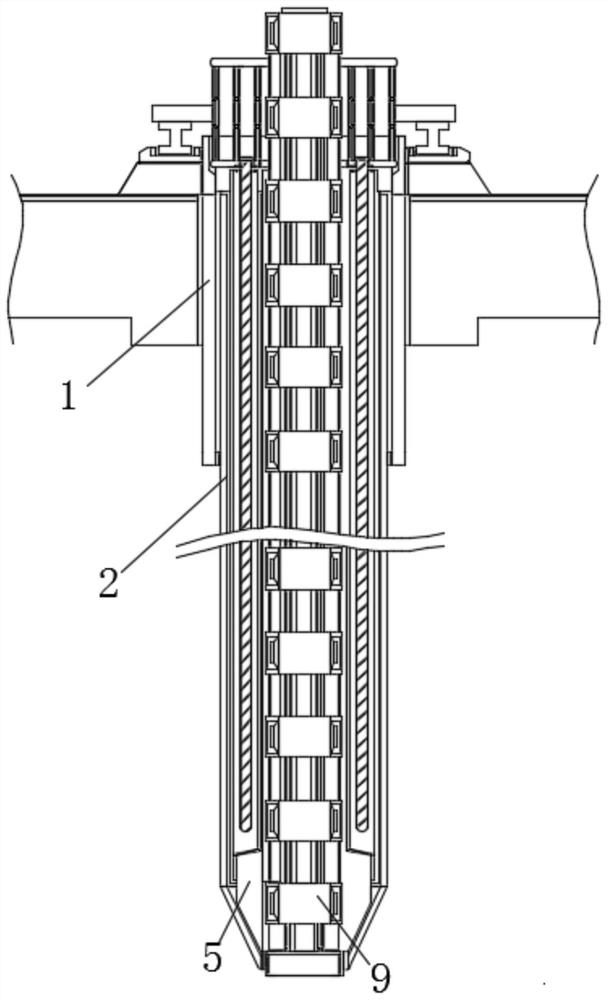

[0045] Example 1, as Figure 1-3 As shown, after the casing 1 is assembled, the outer reinforcement frame 2 is then inserted into the inner layer of the casing 1 in turn, and then the inner reinforcement cage 5 is inserted into the inner layer of the outer reinforcement frame 2, and the axial center of the bottom surface of the inner reinforcement cage 5 Prefabricated hollow tube 6 and concrete channel 7, the lattice column 9 can be inserted into the inner layer of the inner steel cage 5 at this time, and wrapped on the outer wall of the hollow tube 6, so that the internal structure of the formed uplift pile is interconnected and strengthened The anti-offset and bearing capacity of the pile body make the installation work distinct, and enhance the work efficiency of the on-site loading and installation of the uplift pile.

Embodiment 2

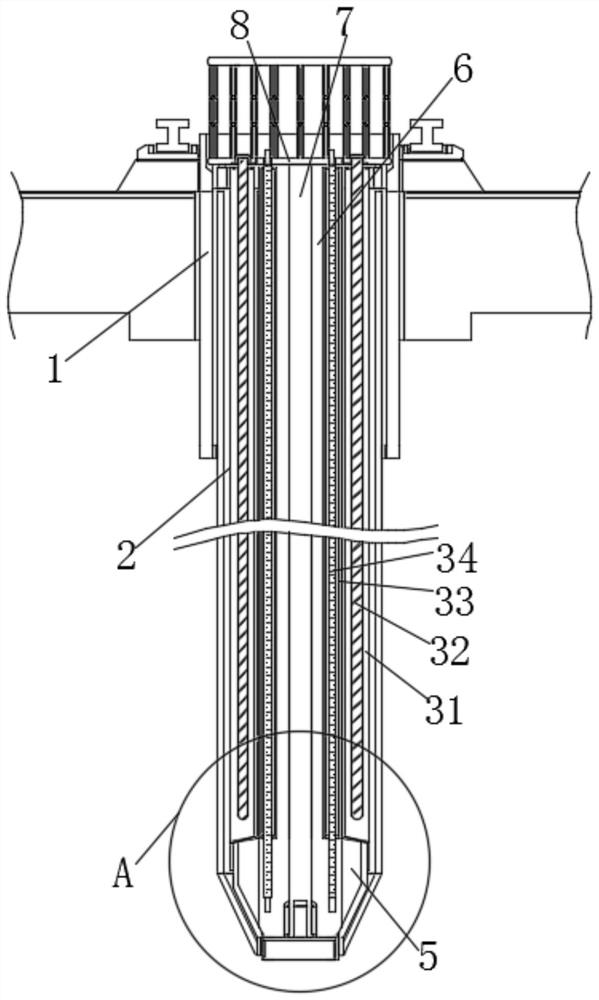

[0046] Example 2, as Figure 4-7 As shown, the reinforcement fence 8 can be prefabricated above the inner reinforcement cage 5, so that the reinforcement fence 8 is higher than the ground at a certain height, and after the protective tube 1, the outer reinforcement frame 2, the inner reinforcement cage 5 and the lattice column 9 are loaded and installed , four groups of prestressed steel strands 32 embedded in the inner cavity of the hollow limit post 31 and the planting bars 34 in the inner cavity of the square tube 33 can be driven above the reinforced fence 8, and finally the filled concrete can be extended to the hollow limit. The inner cavity of the position column 31 and the square tube 33 makes the inner layer filling of the outer reinforcement frame 2 and the inner reinforcement cage 5 more compact, and increases the prestress and the pullout resistance of the pullout pile anchoring structure.

[0047] Example 2, as Figure 8-10 As shown, when the crawler crane 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com