Starch film-forming composition, soft capsule shell and application of soft capsule shell in soft capsule

A composition and soft capsule technology, which is applied in the field of medicine and dietary supplement manufacturing, can solve the problems that soft capsules do not have enteric-coated effect, and achieve stable enteric-coated effect, simple ingredients, and good formability

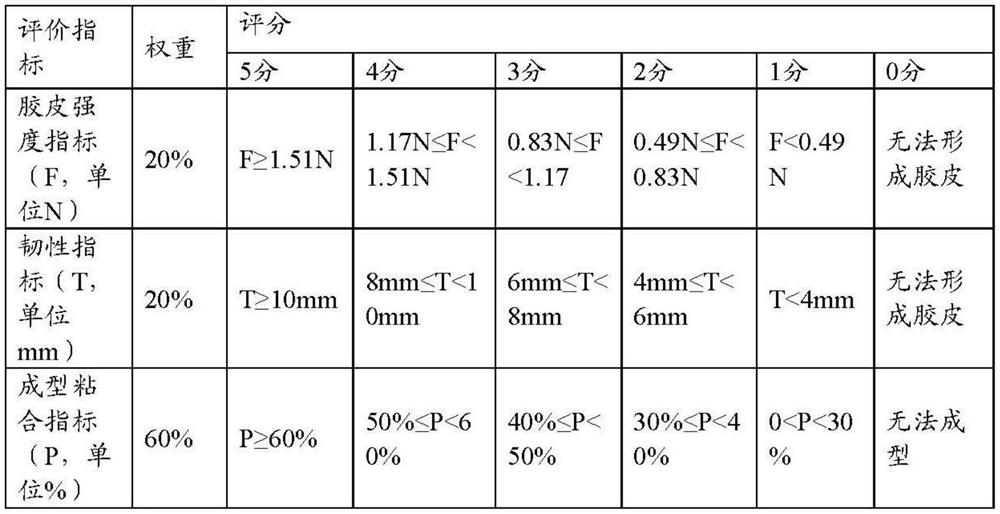

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Soft capsule shells can be prepared from the starch film-forming compositions of the present invention by conventional techniques. For example, the preparation method may include: sol, pelletizing and drying steps. The sol step may include pre-mixing and dispersing the gellan gum and the plasticizer uniformly, adding to an appropriate amount of water under stirring, heating and stirring at 60-98° C. until the gellan gum is dissolved; adding starch, continuing to heat and stirring at 60-98° C. until the starch dissolves; remove the bubbles to get the glue. The pill pressing step may include using a soft capsule production line to transport the glue into the plastic box of the soft capsule filling machine, and the glue is cooled on the surface of the drum to form a rubber skin, which is compressed and formed by packaging and filling, and can be further shaped in a rotating cage. The prepared soft capsule shells were tested to be enteric and had excellent formability.

...

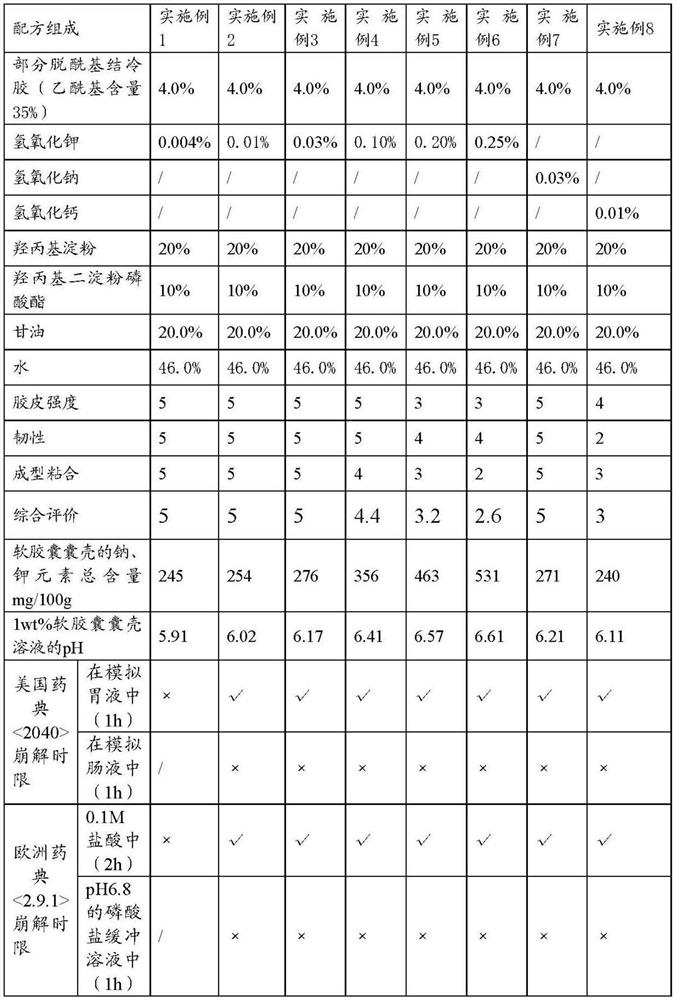

Embodiment 1-8

[0085] Soft capsule shells were prepared using the formulations in Tables 2 and 3 and the above-mentioned method, and the rubber skin strength index, toughness index and molding adhesion index and enteric property were determined according to the above method.

[0086] Table 2: Formulations and measurement results of the starch film-forming compositions of Examples 1-8

[0087]

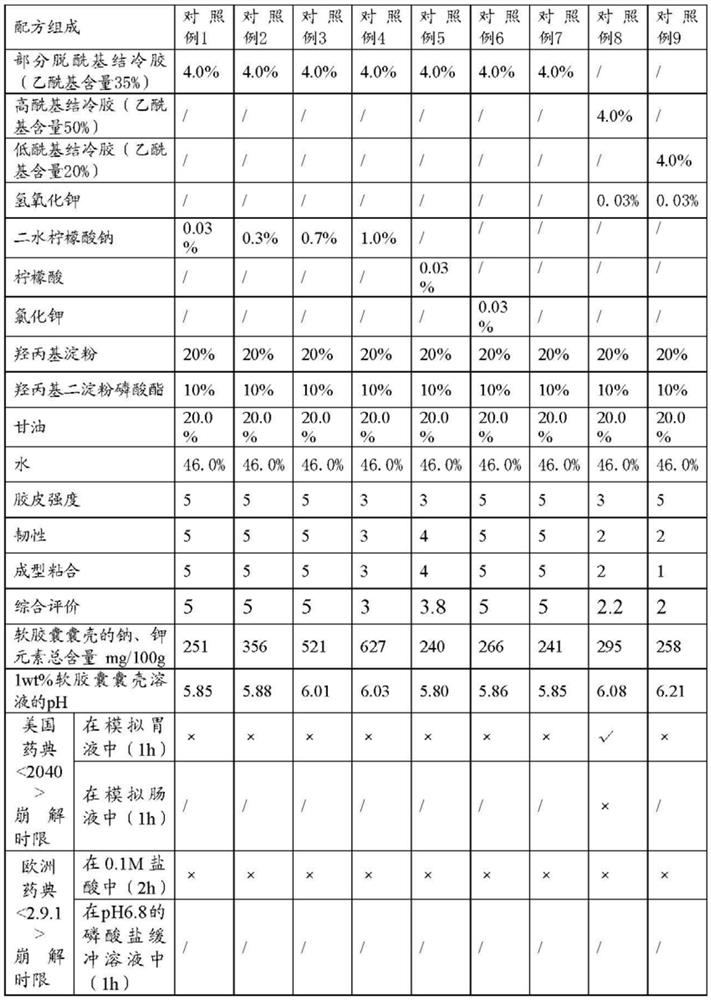

[0088] Table 3: Formulations and measurement results of the starch film-forming compositions of Comparative Examples 1-9

[0089]

[0090] √ not cracked, × cracked, / not tested.

Embodiment 1

[0091] Embodiment 1-6 adopts potassium hydroxide as pH adjuster, and makes soft capsule with the composition of partially deacylated gellan gum, starch, glycerin and water, wherein potassium, The total content of sodium is 245, 254, 276, 356 and 463mg / 100g, all lower than 500mg / 100g, and the comprehensive evaluation of molding is 5, 5, 5, 4.4 and 3.2, all higher than 3.0, suitable for soft capsules However, the pH of the 1% soft capsule shell aqueous solution in Example 1 is 5.91 (6.0. The soft capsules of Examples 2-6 have enteric coating effects, but the examples The comprehensive evaluation of molding of 6 is 2.6 (less than 3.0), the molding viscosity is poor, and the risk of oil leakage is high, which affects the large-scale production of soft capsules.

[0092] Embodiments 7 and 8 adopt sodium hydroxide and calcium hydroxide as pH regulators, and the comprehensive evaluation of its molding is respectively 5 and 3, which are higher than 3.0, and are suitable for large-scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com