Preparation method of benzoxazine-based conjugated trapezoidal polymer and application of benzoxazine-based conjugated trapezoidal polymer in hydrogen sulfide detection

A benzoxazine-based polymer technology, applied in the detection of hydrogen sulfide, the preparation field of benzoxazine-based conjugated ladder polymers, can solve the problems of unmentioned hydrogen sulfide detection performance and different applications , to achieve the effects of low cost, high specificity, good conductivity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

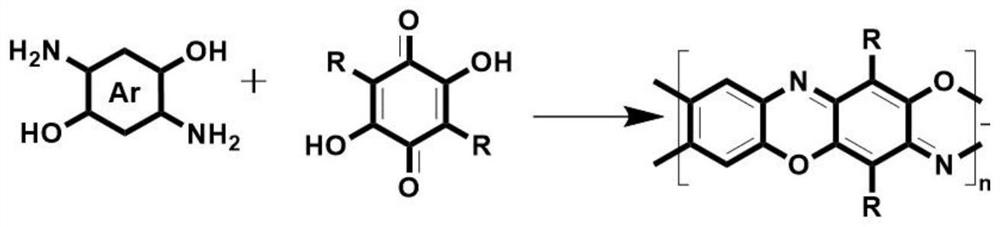

Method used

Image

Examples

Embodiment 1

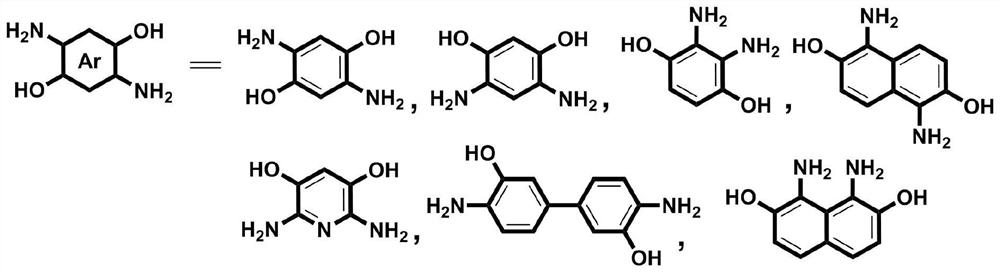

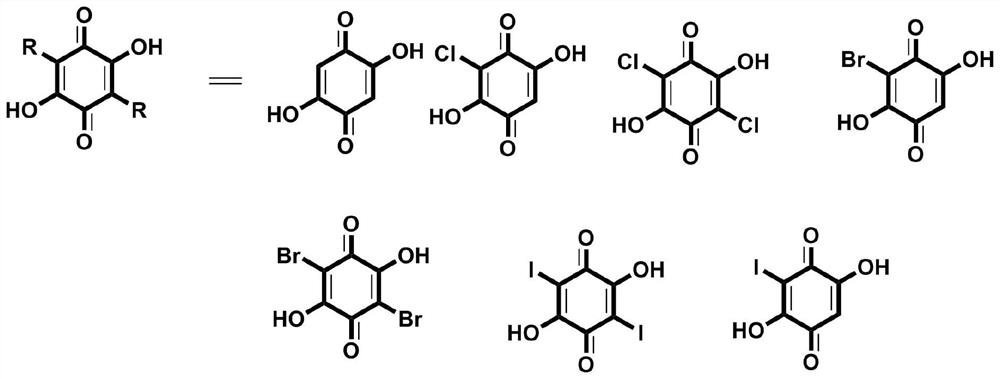

[0034] (1) a preparation method of a benzoxazine-based conjugated ladder polymer, the steps are as follows:

[0035] Add 21.3 grams of A monomer DAR (213.06) and 24.9 grams of B monomer chlororanic acid (208.98) into the polymerization reactor, add 500 ml of anhydrous NMP, and after vacuuming for many times, the temperature is programmed to 140 ° C, and stirring is uniform, Argon gas was bubbled in (flow rate 70 ml / min). The reaction was carried out for 120h. After the reaction, the reaction kettle was cooled to room temperature, poured into a centrifuge tube and centrifuged with ultrapure water, washed 6 times, and washed 3 times with anhydrous ethanol. Dry under vacuum at 60°C for 48h. Take 10 grams of polymer powder and put it into a vacuum atmosphere furnace with a programmed temperature of 300 °C for 2 h. Then program down to room temperature (30 min 10°C). Pour into a centrifuge tube, add ultrapure water for centrifugation, wash 6 times, and wash 3 times with absolut...

Embodiment 2

[0039] (1) a preparation method of a benzoxazine-based conjugated ladder polymer, the steps are as follows:

[0040] 21.3 grams of A monomer DAR (213.06) and 20.8 grams of B monomer chlororanic acid (208.98) were added to the polymerization reactor, 450 ml of anhydrous DMF was added, and after vacuuming for many times, the temperature was programmed to 100 ° C, and the stirring was uniform. Argon gas was bubbled in (flow rate 30 ml / min). Reaction for 24h. After the reaction, the reaction kettle was cooled to room temperature, poured into a centrifuge tube and centrifuged with ultrapure water, washed 6 times, and washed 3 times with anhydrous ethanol. Dry under vacuum at 60°C for 48h. Then the program was lowered to room temperature (30 min at 5°C). Pour into a centrifuge tube, add ultrapure water for centrifugation, wash 6 times, and wash 3 times with absolute ethanol. Dry under vacuum at 60°C for 48h. The benzoxazine-based conjugated ladder polymer powder can be obtained...

Embodiment 3

[0044] (1) a preparation method of a benzoxazine-based conjugated ladder polymer, the steps are as follows:

[0045] Add 14 grams of A monomer 4,6 diaminoresorcinol (140.138) and 15.4 grams of B monomer 2,5-dihydroxybenzoquinone (140.09) into the polymerization reaction kettle, add 480ml of anhydrous NMP, and vacuumize more After the first ventilation, the temperature was programmed to 160° C., stirred evenly, and argon gas was introduced (flow rate 100 ml / min). Reaction for 48h. After the reaction, the reaction kettle was cooled to room temperature, poured into a centrifuge tube and centrifuged with ultrapure water, washed 6 times, and washed 3 times with anhydrous ethanol. Dry under vacuum at 60°C for 48h. Take 5 grams of polymer powder and put it into a vacuum atmosphere furnace with a programmed temperature of 350 °C for 3 h. Then the program was lowered to room temperature (30 min at 5°C). Pour into a centrifuge tube, add ultrapure water for centrifugation, wash 6 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com