Laser-MIG composite double-gun synchronous symmetric welding method for titanium alloy T-shaped joint of medium plate

A compound double-gun, symmetrical welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult shape correction, large cumulative longitudinal bending deformation, and difficult protection of titanium alloy, and achieve flexibility And good accessibility, increase the droplet transfer frequency, enhance the effect of laser penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

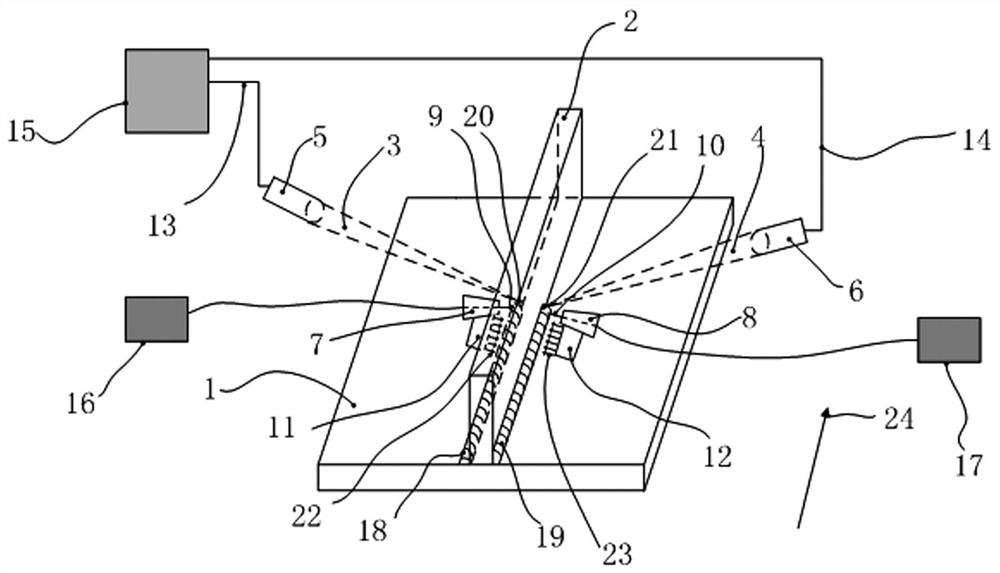

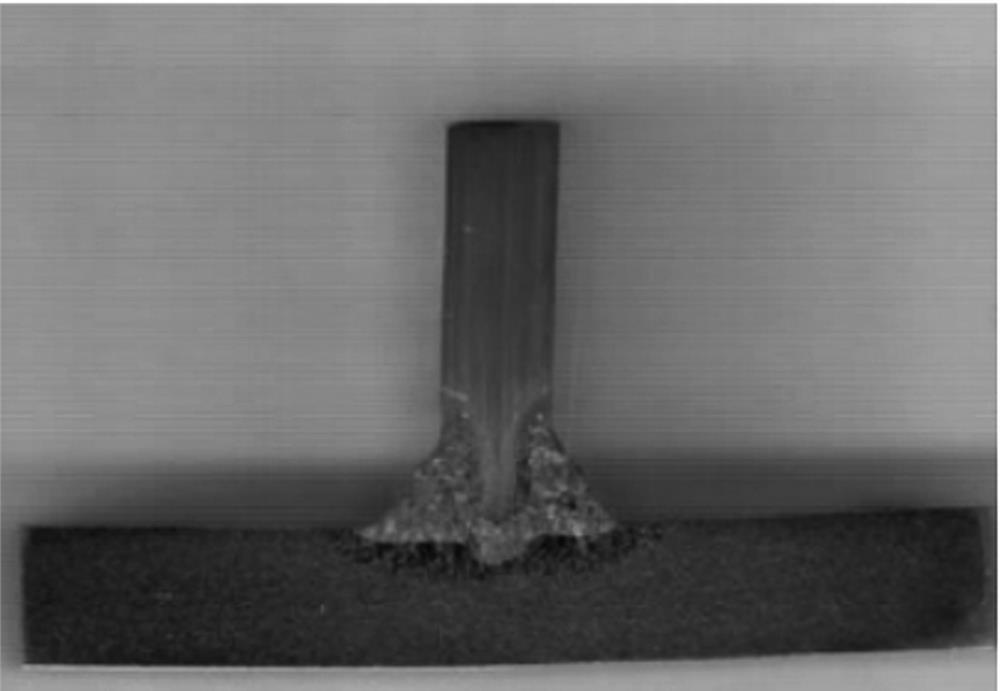

[0051] like figure 2 and image 3 As shown in the figure, the appearance of the TA5 titanium alloy T-joint laser double-gun symmetrical welding joint and the macro-section view of the weld, the thickness of the panel is 6mm, the thickness of the web is 5mm, and the high-power fiber laser-MIG composite double-gun synchronous symmetrical welding is used to achieve The T-joint is welded on both sides at one time, and the welding process specification is selected: the laser power on both sides is 3000W, the defocusing amount is +15mm, the welding speed is 90cm / min, the inclination angle of the composite welding gun is 20° (the angle with the panel), the light filament The distance is 1mm, the angle between the filaments is 30°, the welding arc adopts a unified pulse mode, the welding current is 160A, the voltage is 23V, the wire feeding speed is 6m / min, and the protective gas on the front and back of the welding is 99.99% pure argon.

Embodiment 2

[0053] like Figure 4 and Figure 5 As shown in the figure, the appearance of the laser double gun symmetrical welding joint of Ti80 titanium alloy T-joint and the macro cross-sectional view of the welding seam, the panel and the web are both 18mm, and the 18mm thick T-shaped joint is realized by high-power fiber laser-MIG composite double-gun synchronous symmetrical welding. The joints are formed by one-time welding on both sides, and the welding process specification is selected: the laser power on both sides is 9000W, the defocusing amount is +10mm, the welding speed is 30cm / min, the inclination angle of the composite welding gun is 5° (the angle with the panel), and the filament distance is 2mm. , The included angle of the light wire is 30°, the welding arc adopts a unified pulse mode, the welding current is 220A, the voltage is 28V, the wire feeding speed is 12m / min, and the protective gas on the front and back of the welding is 99.99% pure argon.

[0054] To sum up, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com