A kind of car airbag hinge mesh

A car safety, hinge technology, used in textiles, through-hole fabrics, textiles and paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

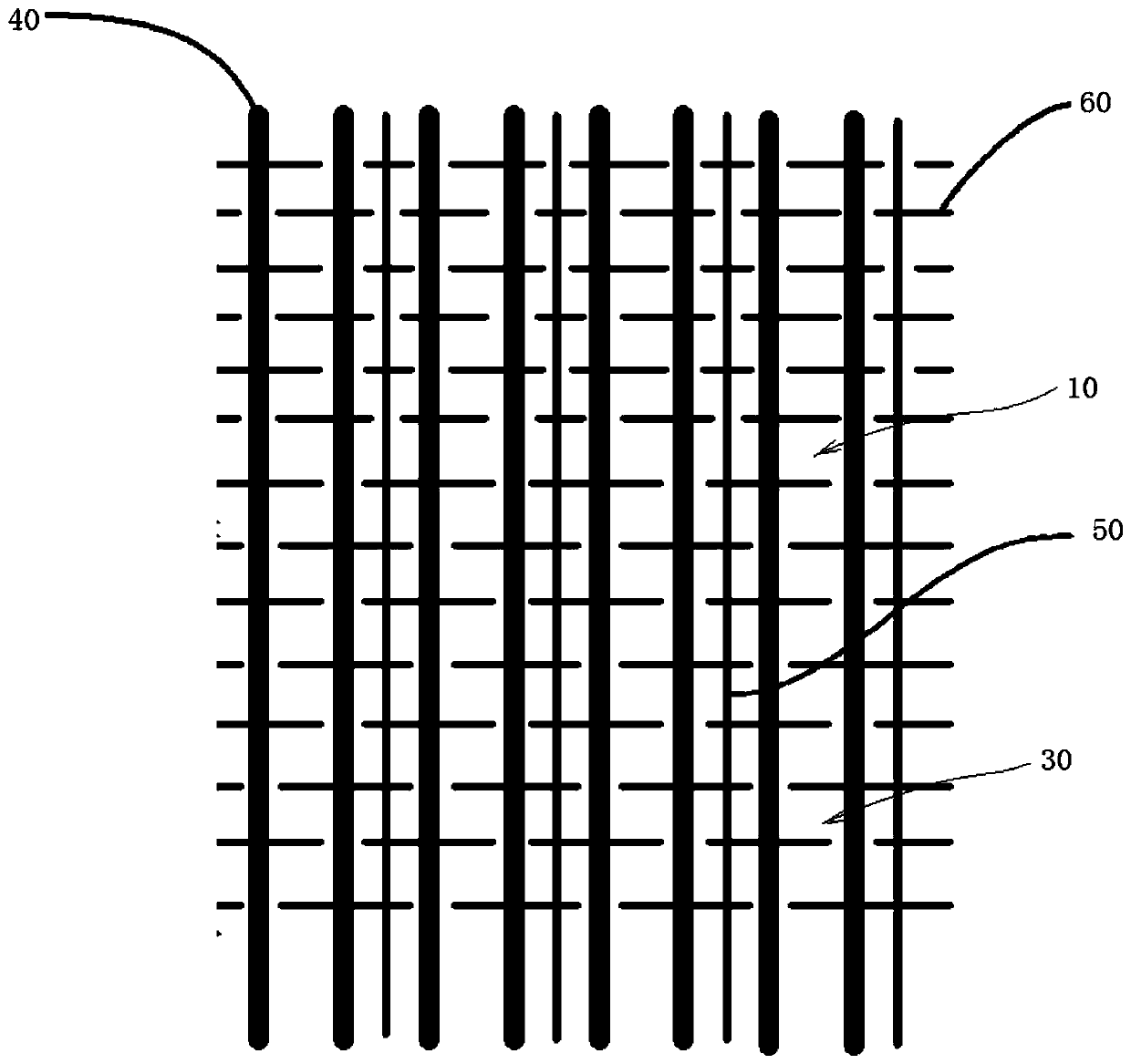

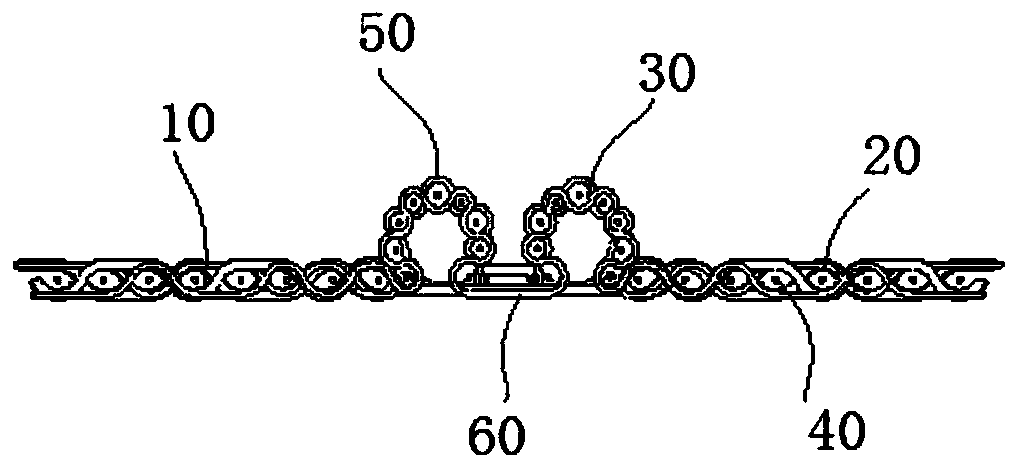

[0024] see Figure 1 to Figure 3 , The car airbag hinge mesh shown in the figure is composed of two mesh structure cloth areas 10, 20 and a hinge mesh cloth storage area 30. The hinge mesh cloth storage area 30 combines the two mesh structure cloth areas 10, 20 and 30. 20 to connect.

[0025] The car airbag hinge mesh is woven with two sets of warp yarns and weft yarns 60. One set of warp yarns in the two sets of warp yarns is high-strength yarn 40, such as: aramid yarn, polyester yarn, carbon fiber yarn, etc. The first choice is aramid yarn , The function of this group of warp yarns woven into cloth is to resist the huge pulling force generated by the opening of the shell when the airbag is exploded.

[0026] Corresponding to the high-strength warp yarns 40, the other group of yarns 50 is made of weaker-strength yarns as the base fabric warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com