Drying furnace for producing low-water-content potassium fluoride

A drying furnace and potassium fluoride technology, applied in spray evaporation, evaporator accessories, etc., can solve the problems of high moisture content, storage and low activity, and difficult transportation of potassium fluoride, and achieve lower boiling temperature and easy evaporation and drying , Increase the effect of floating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

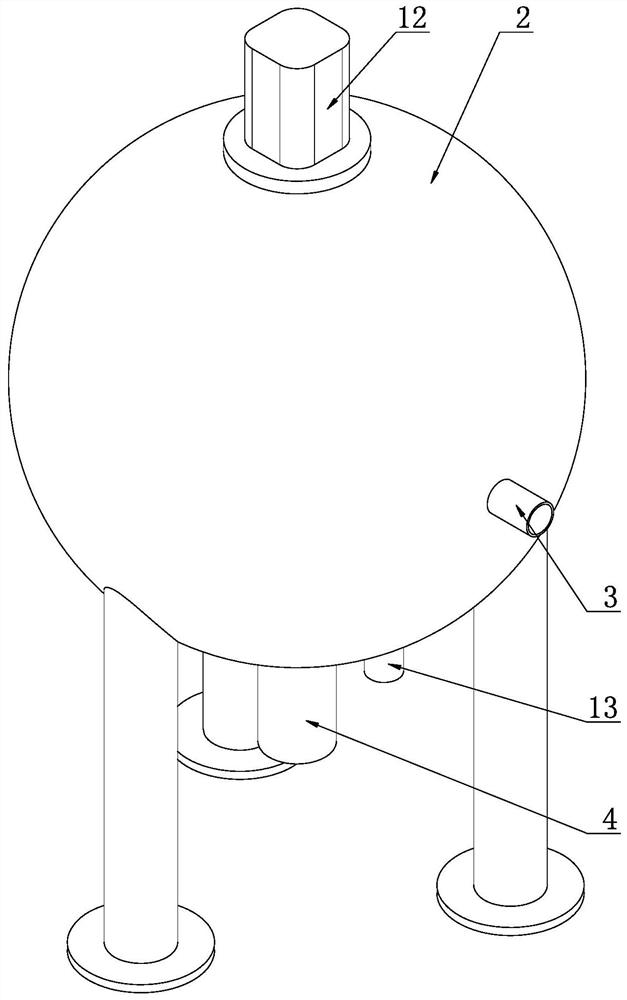

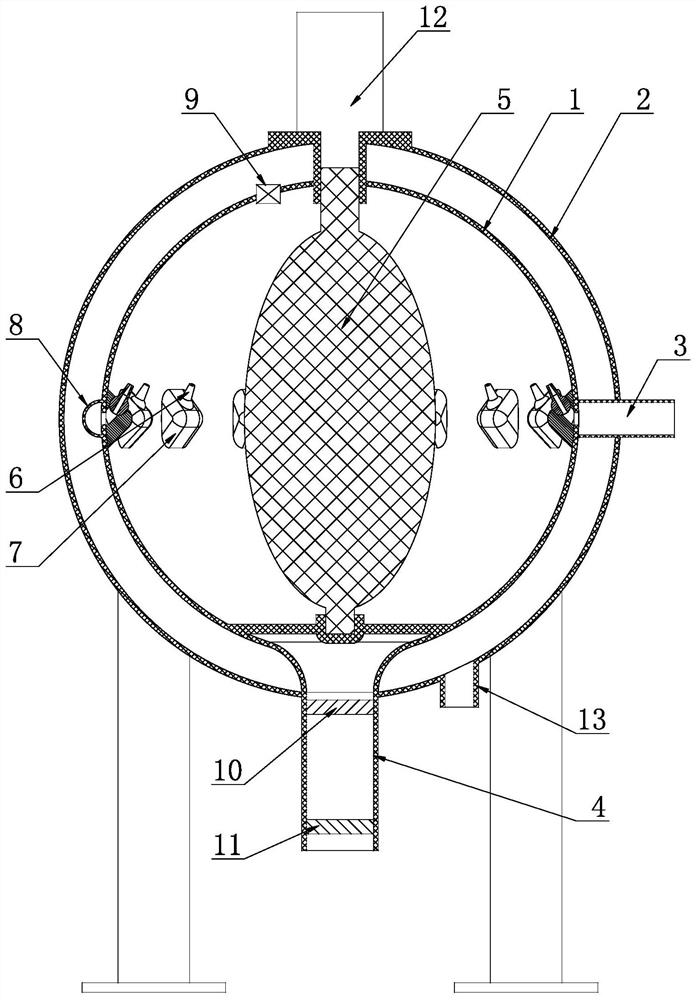

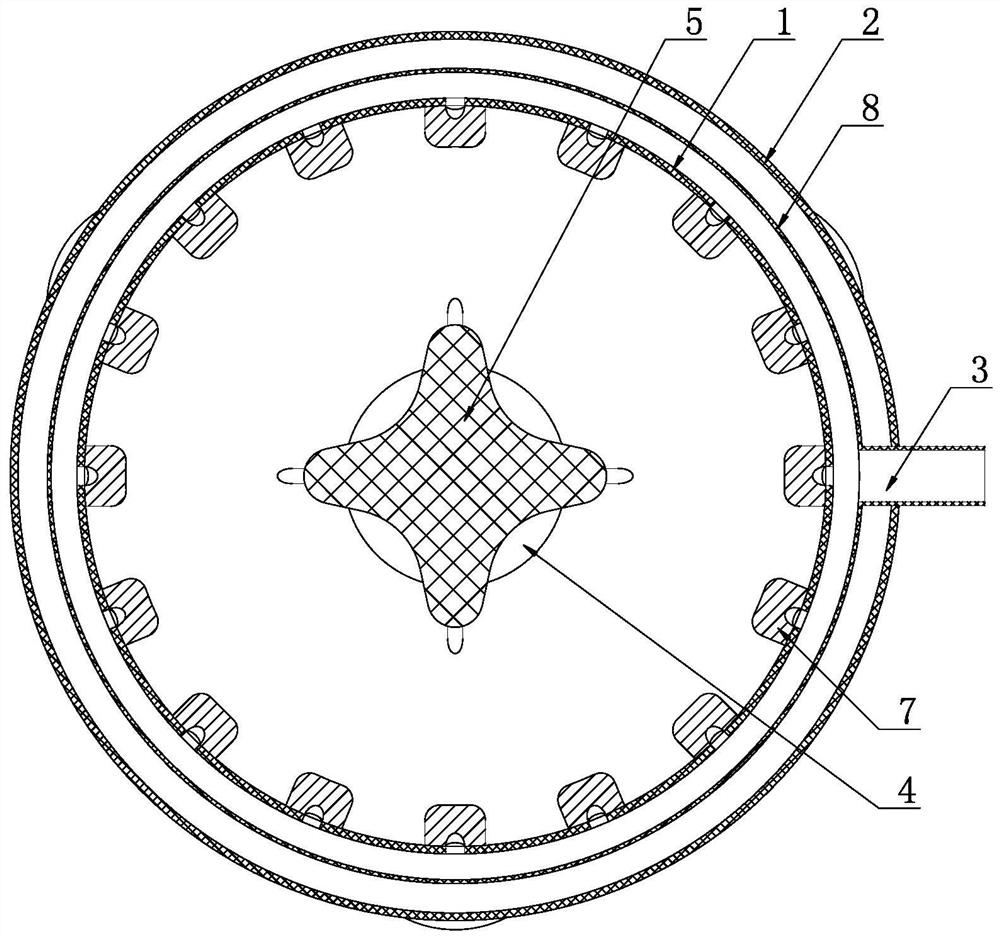

[0039] like Figure 1-10 As shown, a kind of drying furnace for the production of potassium fluoride with low moisture content, the drying furnace is spherical, and the drying furnace comprises an inner shell 1, an outer shell 2, a feeding pipe 3, a discharging pipe 4, a heat source 5 and a nozzle 6, The inner shell 1 and the outer shell 2 are arranged in a parallel and spaced sleeve, the heat source 5 is longitudinally arranged in the inner middle of the inner shell 1, a plurality of spray heads 6 are arranged in an array along the inner circumference of the inner wall of the inner shell 1, and the middle of the feeding pipe 3 is sealed and fixed in the outer shell 2, One end of the feeding pipe 3 located in the outer casing 2 is connected to the nozzle 6, the feeding pipe 4 is vertically arranged at the bottom center of the inner casing 1, the upper end of the feeding pipe 4 is fixedly connected to the inner casing 1, and the lower end extends downwardly from the outer casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com