Method for predicting remaining service life of rolling bearing based on time-varying Kalman filtering

A Kalman filter, Kalman filter technology, applied in special data processing applications, complex mathematical operations, geometric CAD and other directions, can solve the problem of high computational cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0067] (1) Measure the acceleration performance degradation data of rolling bearing, and calculate the root mean square value as the health index. Take the acceleration performance degradation experimental data of rolling bearings published by the University of Cincinnati as an example. The rotating shaft is supported by 4 Rexhord ZA-2115 double row rolling bearings, each bearing is equipped with a sensor on the bearing seat and collects data simultaneously. A load of 6000lbs is applied radially to speed up the bearing degradation process. Data was collected every 10 min, and 980 data were collected by the end of the experiment, with a total time of about 160 h. Among them, the evolution curve of the health index of bearing 2 is as follows image 3 shown by the * mark.

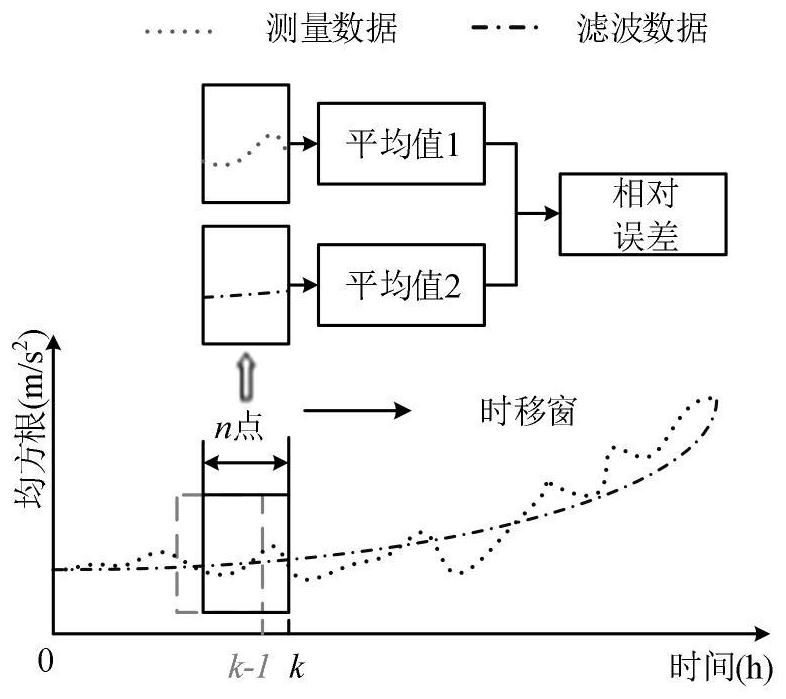

[0068] (2) First, the Kalman filter based on the linear function model i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com